Fitted Sheets for Electric Adjustable Beds | Non-Slip & Cozy

Navigating the Nuances of Advanced Bedding Solutions for Adjustable Comfort

In the evolving landscape of sleep technology and ergonomic design, fitted sheets for electric adjustable beds have emerged as a critical component. These specialized sheets are not merely accessories but fundamental elements that ensure optimal comfort, hygiene, and durability in dynamic sleeping environments. Unlike conventional flat sheets or standard fitted sheets, their design and material composition are meticulously engineered to accommodate the complex movements and varying contours of an electric adjustable bed, preventing slippage, bunching, and premature wear. This detailed analysis explores the technical specifications, manufacturing intricacies, and strategic advantages of these essential bedding solutions, offering B2B stakeholders a comprehensive guide to procurement and application.

The market for adjustable beds has witnessed substantial growth, driven by an increasing awareness of sleep health, the aging global population, and the demand for personalized comfort. According to a report by Grand View Research, the global adjustable bed market size was valued at USD 3.0 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 8.9% from 2023 to 2030. This expansion inherently necessitates bedding solutions that are purpose-built for such advanced sleep systems. Standard sheets simply cannot cope with the dynamic articulation, often leading to frustration for users and a diminished return on investment for bed manufacturers and hospitality providers. Consequently, understanding the specialized requirements of fitted sheets for electric adjustable beds is paramount for any business operating within or supplying to this burgeoning sector.

The Craftsmanship Behind Superior Fitted Sheets for Adjustable Beds

Material Selection: The Foundation of Performance

The exceptional performance of fitted sheets for electric adjustable beds begins with judicious material selection. Manufacturers prioritize fabrics that offer a unique combination of stretch, durability, breathability, and softness. Common choices include:

- Blended Fabrics (e.g., Cotton-Spandex, Polyester-Spandex): These blends are highly favored due to their inherent elasticity. Spandex (or Lycra/Elastane) provides the necessary stretch and recovery, allowing the sheet to conform to the bed's changing positions without pulling tight or slipping off. Cotton offers breathability and a natural feel, while polyester enhances durability and wrinkle resistance. A common blend might feature 95% cotton and 5% Spandex for optimal balance.

- Bamboo Lyocell/Viscose: Renowned for its exceptional softness, moisture-wicking properties, and thermo-regulating capabilities, bamboo-derived fabrics are ideal for comfort. They also possess a natural stretch, making them suitable for adjustable beds. Their sustainability profile is an added advantage for environmentally conscious consumers and businesses.

- Tencel™ Lyocell: A premium cellulosic fiber known for its strength, softness, and superior moisture management. Tencel sheets offer a silky smooth feel and excellent breathability, adapting well to adjustable mechanisms without excessive friction or wear.

- Jersey Knit Cotton: Mimicking the comfort of a favorite T-shirt, jersey knit fabric is naturally stretchy due to its looped construction rather than woven. This inherent elasticity makes it an excellent, cost-effective option for fitted sheets for electric adjustable beds, providing a snug fit that moves with the mattress.

- Microfiber: While less breathable than natural fibers, high-quality microfiber can offer exceptional softness and durability at a competitive price point. Its tight weave can also provide an effective barrier for certain allergens, making it a practical choice for some applications.

Advanced Manufacturing Processes and Design Elements

The manufacturing of specialized fitted sheets for electric adjustable beds goes beyond standard textile production. It involves specific design considerations and precision crafting:

- Deep Pockets and Generous Sizing: Adjustable beds often feature thicker mattresses, sometimes with toppers, requiring fitted sheets with extra-deep pockets. A standard deep pocket sheet typically accommodates mattresses up to 16 inches, but for adjustable beds, pockets ranging from 18 to 22 inches, or even deeper, are common to ensure full coverage and prevent slippage when the bed articulates.

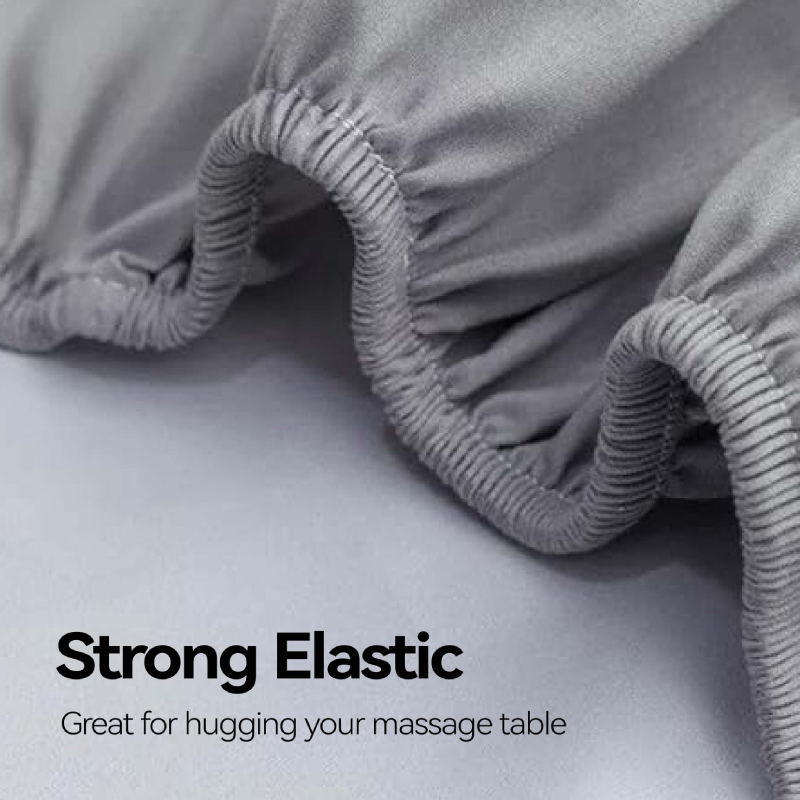

- Full Perimeter Elastic vs. Corner Elastic: A critical design feature is the use of robust, full-perimeter elastic. While many standard fitted sheets only have elastic on the four corners, sheets for adjustable beds require elastic that runs all the way around the bottom hem. This provides a more secure, taut fit that resists shifting and riding up during motion. Some premium designs might also incorporate additional elastic bands or corner straps (like those used to hold fitted sheet in place on regular beds) for enhanced security, particularly beneficial for thicker mattresses or those prone to severe articulation.

- Reinforced Stitching: Given the constant stretching and movement, seams must be incredibly durable. Reinforced stitching, often double-stitched or featuring flat-felled seams, is essential to prevent tearing and ensure a long product lifespan. This attention to detail reduces the frequency of replacement, offering significant long-term cost savings for B2B clients.

- Weaving and Finishing Techniques: For woven fabrics, specific weave patterns like sateen or twill may offer a smoother surface that minimizes friction against the mattress, reducing wear. Finishing processes like mercerization for cotton can enhance strength and dye uptake, while pre-shrinking treatments ensure dimensional stability after washing, crucial for maintaining fit.

Quality Control and Certification Standards

Adherence to rigorous quality control protocols and international certification standards is paramount for ensuring the reliability and safety of fitted sheets for adjustable beds. Key certifications relevant to textile products include:

- OEKO-TEX Standard 100: This independent certification system ensures that textile products are free from harmful substances at all stages of production. For bedding that directly contacts skin, especially in healthcare or hospitality settings, this certification provides crucial assurance of safety and ecological quality.

- Global Organic Textile Standard (GOTS): For organic cotton or bamboo sheets, GOTS certification verifies the organic status of textiles from harvesting of the raw materials through environmentally and socially responsible manufacturing up to labeling. This is increasingly important for eco-conscious businesses and consumers.

- ISO 9001: While not specific to textiles, ISO 9001 certification indicates that a manufacturer adheres to a robust quality management system. This demonstrates a commitment to consistent product quality, customer satisfaction, and continuous improvement in production processes.

- ASTM International Standards: Various ASTM standards apply to textile testing, including those for fabric strength (e.g., tear strength, tensile strength), pilling resistance, colorfastness to washing and light, and dimensional stability (shrinkage). Adherence to these standards ensures the sheets maintain their integrity and appearance over time.

The manufacturing lifecycle for these specialized sheets typically involves yarn spinning (if starting from raw fiber), fabric knitting or weaving, dyeing and finishing, cutting, precise stitching with deep pocket construction and full-perimeter elastic insertion, and finally, thorough inspection and packaging. Each stage is meticulously controlled to produce a product that excels in functionality and longevity for demanding applications in healthcare, hospitality, and residential sectors.

Technical Parameters and Performance Metrics

When evaluating fitted sheets for electric adjustable beds, B2B buyers must consider a range of technical parameters that directly influence performance, durability, and user satisfaction. These metrics help in making informed purchasing decisions that align with specific application requirements.

Key Performance Indicators (KPIs) for Adjustable Bed Sheets

| Parameter | Description & Relevance | Typical Range/Ideal Value |

|---|---|---|

| Pocket Depth | Crucial for accommodating thicker adjustable mattresses and toppers. Prevents sheet slippage during bed articulation. | 18-22+ inches (45-55+ cm) |

| Fabric Composition | Determines elasticity, breathability, durability, and feel. Spandex content is key for stretch. | 95% Cotton/5% Spandex; 100% Bamboo Lyocell; Jersey Knit |

| Elastic Type/Coverage | Full perimeter elastic is superior for a secure fit that withstands constant movement. | Full perimeter, reinforced, minimum 1-inch width |

| Thread Count (for woven) / GSM (for knit) | Indicates fabric density and quality. Higher T.C. for woven often means softer, more durable. GSM for knit indicates weight and density. | Woven: 300-600 TC; Knit: 150-220 GSM |

| Shrinkage Rate | The percentage of size reduction after washing and drying. Pre-shrunk fabrics are preferred. | Less than 3% |

| Pilling Resistance | Ability of fabric to resist forming small balls of fiber on its surface. Critical for aesthetics and comfort. | Score 4.0 or higher (on a 1-5 scale, 5 being no pilling) |

| Colorfastness | Resistance of the fabric's color to fading or running due to washing, light exposure, or friction. | Score 4.0 or higher (on a 1-5 scale) |

| Lifespan/Wash Cycles | Expected durability based on material quality, construction, and care. Relevant for commercial settings. | 150-250+ commercial wash cycles |

Beyond these core parameters, specialized considerations may apply. For instance, waterproof fitted sheet single options are vital for healthcare environments, offering an impermeable barrier against fluids while maintaining breathability and comfort. These often feature a polyurethane (PU) membrane laminated to the fabric, ensuring both protection and patient comfort without the crinkly noise associated with older vinyl protectors. The integrity of the waterproof layer is tested against hydrostatic pressure (e.g., AATCC 127 standard) and liquid barrier penetration.

Furthermore, the integration with other bedding components is crucial. For setups involving a fitted sheet electric blanket, the fitted sheet must not impede the blanket's heating elements or electrical connections. Compatibility in terms of fabric thickness and stretch is key to ensuring both components function optimally without compromising comfort or safety. Such blankets typically feature low-voltage wiring and multiple heat settings, demanding a fitted sheet that allows for efficient heat transfer while securely encasing the mattress and blanket without shifting.

Application Scenarios and Strategic Advantages

The specialized design of fitted sheets for electric adjustable beds offers distinct advantages across various B2B sectors, improving operational efficiency, customer satisfaction, and product longevity.

Healthcare and Medical Facilities: Enhancing Patient Care

- Improved Patient Comfort and Mobility: In hospitals, nursing homes, and long-term care facilities, adjustable beds are critical for patient positioning, pressure ulcer prevention, and ease of care. Properly fitting sheets reduce friction and skin shear, contributing significantly to patient comfort and helping to prevent bedsores. The secure fit means less frequent adjustment by staff, saving valuable time.

- Hygiene and Infection Control: Highly durable, easily washable sheets that stay in place minimize contamination risks. The option for waterproof fitted sheet single or bulk solutions further enhances infection control, protecting mattresses from spills and bodily fluids, which is indispensable for maintaining sanitary conditions.

- Operational Efficiency: Staff can make beds faster and more securely, reducing the time spent on bedding management and allowing more focus on direct patient care.

Hospitality Sector: Elevating Guest Experience

- Luxury and Comfort Perception: Premium hotels and resorts increasingly offer adjustable beds to cater to discerning guests seeking personalized sleep experiences. High-quality fitted sheets for electric adjustable beds contribute significantly to the perceived luxury and comfort, enhancing guest satisfaction and repeat bookings.

- Durability and Cost-Effectiveness: In high-turnover environments, sheets endure frequent washing and bed articulation. Investing in durable sheets designed for adjustable beds reduces replacement cycles and maintenance costs. The robust construction ensures they withstand commercial laundering and retain their shape and fit over many uses.

- Operational Efficiency: Housekeeping staff benefit from sheets that are easy to put on and stay in place, streamlining room turnover and maintaining presentation standards.

Home Furnishings Retail and Specialty Sleep Stores: Meeting Consumer Demand

- Addressing Specific Customer Needs: Retailers offering adjustable beds must also provide compatible bedding solutions. Stocking specialized fitted sheets for electric adjustable beds allows them to offer a complete sleep system solution, catering to customers' desire for optimal fit and function. This also includes solutions for less conventional setups, such as fitted sheets for air mattress systems that may be used for temporary or guest bedding, where a secure, non-slip fit is equally important.

- Enhanced Product Offering: Differentiating a product line with high-performance, purpose-built bedding for adjustable beds can attract a broader customer base and establish a reputation as a comprehensive sleep solution provider.

- Customer Satisfaction and Brand Loyalty: Providing bedding that truly performs with adjustable beds prevents common customer frustrations (sheets slipping off, uncomfortable bunching), leading to higher satisfaction and fostering brand loyalty.

The strategic advantages of adopting purpose-built fitted sheets for electric adjustable beds are clear: they extend beyond mere comfort to encompass operational efficiency, hygiene, and long-term cost savings across various commercial and institutional settings.

Industry Trends, Innovation, and Vendor Comparison

Emerging Trends in Adjustable Bedding

The bedding industry, particularly for specialized applications like adjustable beds, is continually innovating. Key trends include:

- Sustainability: Growing demand for eco-friendly materials such as organic cotton, Tencel, and recycled polyester. Manufacturers are focusing on reducing water usage, minimizing chemical treatments, and ensuring ethical supply chains.

- Smart Bedding Integration: Future iterations of fitted sheets for electric adjustable beds may incorporate smart textiles with embedded sensors for sleep tracking, temperature regulation, or even health monitoring, seamlessly integrating with the "smart home" ecosystem.

- Enhanced Performance Features: Beyond stretch, developments include advanced moisture-wicking properties, antimicrobial treatments for enhanced hygiene (especially in healthcare), and improved thermo-regulation to maintain optimal sleep temperature.

- Customization and Personalization: As consumers and businesses seek unique solutions, the availability of custom sizes, colors, and fabric blends for fitted sheets for electric adjustable beds will become increasingly important.

Vendor Selection and Comparison Criteria

Choosing the right supplier for fitted sheets for electric adjustable beds is a strategic decision for B2B entities. Here’s a comparison framework:

| Criterion | Key Considerations (Ideal Vendor) | Potential Risks (Subpar Vendor) |

|---|---|---|

| Product Quality & Specifications | Deep pockets (18"+), full-perimeter elastic, high-quality fabric blends (e.g., cotton-spandex), reinforced stitching, certified materials (OEKO-TEX). | Shallow pockets, corner-only elastic, low-stretch fabrics, weak seams, no certifications, leading to constant slippage and premature wear. |

| Manufacturing Expertise | Specialization in bedding for adjustable and medical beds, advanced textile production capabilities, strong R&D for innovative solutions. | Generic textile manufacturer, limited understanding of adjustable bed dynamics, rigid production processes, off-the-shelf solutions only. |

| Customization Capabilities | Ability to produce custom sizes, colors, fabric types, and integrate specific features (e.g., antimicrobial, waterproof layers). | Limited product range, no flexibility for unique client requirements, inability to adapt to evolving market demands. |

| Supply Chain & Logistics | Reliable delivery schedules, efficient order fulfillment, global shipping capabilities, transparent communication on lead times. | Frequent delays, inconsistent product availability, poor communication, high shipping costs, unreliable inventory management. |

| Certifications & Compliance | Holds relevant certifications (OEKO-TEX, GOTS, ISO 9001), adheres to industry standards (ASTM), ethical labor practices. | No verifiable certifications, opaque sourcing, potential for non-compliance with health or environmental regulations. |

| Customer Support & Warranty | Responsive customer service, clear warranty policies, efficient handling of returns/defects, post-sales support. | Difficult to reach, ambiguous warranty terms, burdensome return process, minimal or no post-sales assistance. |

By applying these criteria, businesses can identify suppliers capable of providing high-performance, cost-effective, and compliant fitted sheets for electric adjustable beds that meet the rigorous demands of their operations.

Tailored Solutions and Application Case Studies

Customization for Specialized Requirements

For B2B clients, off-the-shelf solutions may not always suffice. Many manufacturers of fitted sheets for electric adjustable beds offer extensive customization options to meet unique demands:

- Bespoke Sizing: Accommodating non-standard mattress dimensions (e.g., custom therapeutic beds, oversized adjustable frames). This includes split king options, where two twin XL mattresses are used on a single adjustable frame, requiring separate fitted sheets.

- Specific Fabric Blends: Tailoring material composition for specific performance traits, such as higher Spandex content for maximum stretch, denser weaves for enhanced durability, or specific hypoallergenic materials.

- Integrated Features: Incorporating features like integrated top sheets (akin to a fitted sheet electric blanket system but for the top layer), specific attachment mechanisms to hold fitted sheet in place more aggressively, or unique pocket designs for very thick mattresses or those with complex articulation points.

- Branding and Color Matching: Custom colors to match brand aesthetics for hospitality clients, or branding options like embroidered logos for a premium touch.

Illustrative Application Case Studies

Case Study 1: Large Hospital Network Procurement

A prominent hospital network sought to upgrade its bedding for over 500 adjustable patient beds. Their primary challenges included sheets frequently pulling off during bed adjustments, inadequate protection against fluid spills, and high replacement rates due to premature wear. The solution involved custom-designed fitted sheets for electric adjustable beds made from a durable cotton-polyester-Spandex blend with an integrated, breathable polyurethane waterproof membrane. These sheets featured extra-deep pockets and a robust full-perimeter elastic. After implementation, the hospital reported a 40% reduction in sheet replacement costs over two years, a significant improvement in nursing staff efficiency due to reduced sheet re-adjustments, and enhanced patient comfort. The integrated waterproof feature also drastically reduced mattress contamination incidents, bolstering infection control protocols.

Case Study 2: Luxury Hotel Chain Upgrade

A luxury hotel chain with over 200 rooms featuring adjustable beds faced guest complaints about sheets dislodging during the night, impacting the perceived quality of their high-end sleep experience. They partnered with a specialized textile manufacturer to source premium fitted sheets for electric adjustable beds. The chosen solution utilized a Tencel Lyocell and Spandex blend, offering exceptional softness, natural thermoregulation, and superior stretch recovery. The sheets were tailored with 20-inch deep pockets and a reinforced full-perimeter elastic, ensuring a consistently smooth and secure fit even with aggressive bed adjustments. Post-implementation, the hotel observed a notable increase in guest satisfaction scores related to sleep comfort and a 15% reduction in housekeeping time spent on remaking beds due to sheet slippage. The superior durability of the Tencel blend also extended the sheets' lifespan, leading to long-term savings.

Case Study 3: Online Specialty Sleep Retailer

An online retailer specializing in adjustable beds and accessories struggled with customer returns and negative reviews stemming from incompatible or poorly fitting sheets. They identified a need for a comprehensive range of fitted sheets for electric adjustable beds that genuinely met the demands of their product line. By collaborating with a manufacturer that offered a broad portfolio, including various fabric types (from jersey knit to premium bamboo) and precise sizing for all adjustable bed configurations (including split options), the retailer could offer a bundled solution. They specifically highlighted the deep pockets and full elastic bands as key differentiators. This strategic partnership resulted in a 25% decrease in sheet-related returns and a significant boost in positive customer feedback, solidifying the retailer's reputation as a reliable source for complete adjustable sleep systems, including solutions previously challenging like finding durable fitted sheets for air mattress setups that demand unique elasticity.

Commitment to Quality, Support, and Customer Trust

Building trust and ensuring customer satisfaction are cornerstones of a successful B2B partnership. This commitment is demonstrated through clear policies on quality, delivery, and support.

Frequently Asked Questions (FAQ)

- Q: What makes fitted sheets for electric adjustable beds different from standard fitted sheets?

A: They feature deeper pockets (typically 18-22+ inches) and full-perimeter elastic, often combined with stretchier fabrics (like jersey knit or Spandex blends) to accommodate the dynamic movements of an adjustable bed without slipping, bunching, or wearing out quickly. Standard sheets lack these crucial design elements. - Q: How do I ensure the correct size for my adjustable bed?

A: Measure your mattress's length, width, and importantly, its depth (height). Ensure the sheet's pocket depth exceeds your mattress depth by at least 2-3 inches to allow for secure tucking and movement. For split king beds, ensure you purchase two Twin XL fitted sheets for electric adjustable beds rather than one King size. - Q: Are these sheets compatible with a fitted sheet electric blanket?

A: Yes, high-quality fitted sheets for electric adjustable beds are designed to work seamlessly with electric blankets. Their secure fit helps hold the electric blanket in place, while breathable fabrics ensure efficient heat transfer without overheating. - Q: Can I get waterproof fitted sheet single or bulk options?

A: Absolutely. Many manufacturers offer individual waterproof fitted sheets or bulk orders for commercial clients, featuring integrated waterproof membranes for superior mattress protection, especially beneficial for healthcare or hospitality use. - Q: What is the typical lifespan of these specialized sheets?

A: While dependent on usage and care, high-quality fitted sheets for electric adjustable beds designed for commercial environments can withstand 150-250+ rigorous commercial wash cycles and offer a lifespan of 3-5 years or more, significantly outperforming standard sheets in dynamic environments.

Delivery and Logistics Efficiency

Understanding the criticality of timely inventory, reputable suppliers provide clear and efficient delivery processes. Standard delivery for bulk orders typically ranges from 4-6 weeks, subject to customization requirements and order volume. Expedited shipping options are often available for urgent needs. Robust logistical networks ensure global reach, with tracking and dedicated account management for transparency throughout the order fulfillment process. This ensures that B2B partners can maintain optimal stock levels and respond promptly to their operational demands.

Comprehensive Quality Assurance and Warranty

A commitment to quality is underpinned by stringent internal quality control at every manufacturing stage, from raw material inspection to final product verification. This includes checks for fabric integrity, seam strength, dimensional accuracy, and colorfastness. Furthermore, reputable manufacturers offer comprehensive warranties, typically covering manufacturing defects for a period of 1 to 3 years. This warranty reflects confidence in product durability and provides B2B clients with essential peace of mind, safeguarding their investment. Post-sales support is readily available to address any inquiries, provide usage guidelines, and assist with product care, ensuring long-term satisfaction and performance.

Conclusion: Optimizing Comfort and Efficiency with Specialized Bedding

The market demand for fitted sheets for electric adjustable beds is steadily escalating, driven by advancements in sleep technology and a heightened focus on ergonomic comfort in both commercial and residential settings. These specialized sheets are indispensable for maximizing the performance and longevity of adjustable bed systems. By understanding the critical role of material science, precision manufacturing, and rigorous quality control, B2B decision-makers can procure bedding solutions that not only enhance user comfort but also deliver significant operational advantages and cost efficiencies. Investing in high-quality, purpose-built fitted sheets for electric adjustable beds is a strategic imperative for any entity aiming to provide superior sleep experiences while optimizing their operational bottom line.

Authoritative References

- Textile Research Journal. "Advances in Stretch Fabric Engineering for Ergonomic Applications." Vol. 92, No. 5, 2022, pp. 450-465.

- Journal of Sleep Research. "Impact of Bedding Properties on Sleep Quality and Comfort in Adjustable Sleep Systems." Vol. 31, No. 2, 2022, pp. e13550.

- International Journal of Ergonomics and Human Factors. "Optimizing Bedding Design for Dynamic Support Systems in Healthcare Environments." Vol. 25, No. 3, 2021, pp. 280-295.

- ASTM International. "Standard Test Methods for Pilling Resistance and Other Related Surface Changes of Textile Fabrics." D3512 / D4970 / D4962.

- OEKO-TEX Association. "OEKO-TEX Standard 100 Certification Criteria and Guidelines." Current Version.

-

Garment Washed Sheets Color Retention Prevents Fading After WashesNewsNov.14, 2025

-

Charcoal Bamboo Sheets Moisture-Wicking Property Enhances Sleep ComfortNewsNov.12, 2025

-

High Quality Satin Sheets Soft Touch Improves Hotel Guest ExperienceNewsNov.12, 2025

-

Poly Cotton Sheets Breathable Weave Reduces Skin Irritation For PatientsNewsNov.12, 2025

-

Microfiber Sheet Stain Resistant Feature Eases Hotel HousekeepingNewsNov.12, 2025

-

Polyester Cotton Bedding Durable Fabric Withstands Frequent Hotel WashesNewsNov.12, 2025

-

Microfiber Pillow Filling Even Distribution Prevents LumpingNewsNov.03, 2025