Luxury Bed Pillows: Ultimate Comfort & Support for Sleep

The Critical Role of Advanced Bed Pillows in Hospitality and Healthcare

In the demanding environments of hospitality and healthcare, the selection of bedding plays a pivotal role in guest and patient satisfaction, operational efficiency, and overall hygiene. Among these, high-quality bed pillows are not merely comfort accessories but critical components influencing sleep quality, postural support, and infection control. This article delves into the intricate world of advanced bedding solutions, examining industry trends, technical specifications, and the comprehensive manufacturing processes that define superior products designed for B2B applications.

Understanding the material science, construction methodologies, and testing protocols behind durable and hygienic bedding is essential for procurement professionals seeking to optimize their investment. From innovative fill materials to resilient casings and stringent sanitization capabilities, every aspect contributes to a product's longevity and performance in high-usage settings.

Current Industry Trends in Bedding Solutions

The bedding industry, particularly for B2B applications in hospitality and healthcare, is experiencing significant shifts driven by consumer expectations and technological advancements. Key trends include:

- Sustainability and Eco-Friendliness: Growing demand for products made from recycled, organic, or sustainably sourced materials. Certifications like GOTS (Global Organic Textile Standard) and OEKO-TEX are becoming standard benchmarks for transparency and reduced environmental impact.

- Enhanced Hygiene and Antimicrobial Properties: Especially critical in healthcare, but also increasingly important in hospitality. Materials treated with silver ions or other antimicrobial agents, alongside casings designed for easy and effective sanitization, are highly sought after.

- Customization and Personalization: Hotels increasingly offer pillow menus, requiring a diverse range of bed pillows in terms of firmness, loft, and fill type. Healthcare facilities require specialized pillows for patient comfort and pressure relief.

- Durability and Longevity: B2B environments demand products that withstand frequent industrial laundering without compromising structural integrity or comfort. This translates to higher initial investment but lower total cost of ownership (TCO).

- Smart Bedding Integration: While still emerging, "smart" textiles that regulate temperature, monitor sleep patterns, or integrate with facility management systems are on the horizon.

Beyond bed pillows, there's an increasing emphasis on complete bedding solutions, including high-quality linen set options, durable linen quilt choices, aesthetically pleasing and functional bed skirt designs, and comfortable pillow top mattress enhancements, all designed to meet stringent industry standards.

Technical Specifications and Parameters of Bed Pillows

The performance of a bed pillows is defined by a combination of material science and design parameters. Understanding these technical aspects is crucial for informed procurement decisions.

Key Parameters:

- Fill Material: Determines loft, firmness, and hypoallergenic properties. Common fills include:

- Polyester Fiberfill (Synthetic): Affordable, hypoallergenic, and machine washable. Density is measured in grams per square meter (GSM) or ounces per cubic foot. Often spiral-spun for resilience.

- Down/Feather: Luxurious, breathable, and offers excellent insulation. Fill power (measured in cubic inches per ounce) indicates loft and quality.

- Memory Foam: Conforms to the head and neck, offering superior pressure relief. Density (pounds per cubic foot) is a key indicator of support and durability. Often CertiPUR-US certified for emissions and content.

- Latex: Natural or synthetic, offers resilient support and is often hypoallergenic and antimicrobial. Pin-core construction enhances breathability.

- Casing Material: The outer fabric impacts durability, breathability, and feel.

- Cotton (Percale/Sateen): Thread count (TC) is critical; T200-T300 percale offers a crisp, matte finish suitable for institutional use, while sateen provides a softer, lustrous feel. Our Wholesale hospital T130 percale bed sheet example highlights the importance of durable, low-maintenance cotton blends for high-traffic environments.

- Polyester/Poly-Cotton Blends: Offer enhanced durability, wrinkle resistance, and faster drying times, crucial for industrial laundering.

- Waterproof/Antimicrobial Casings: Essential for healthcare, often made from polyurethane-coated fabrics or vinyl for barrier protection against fluids and allergens.

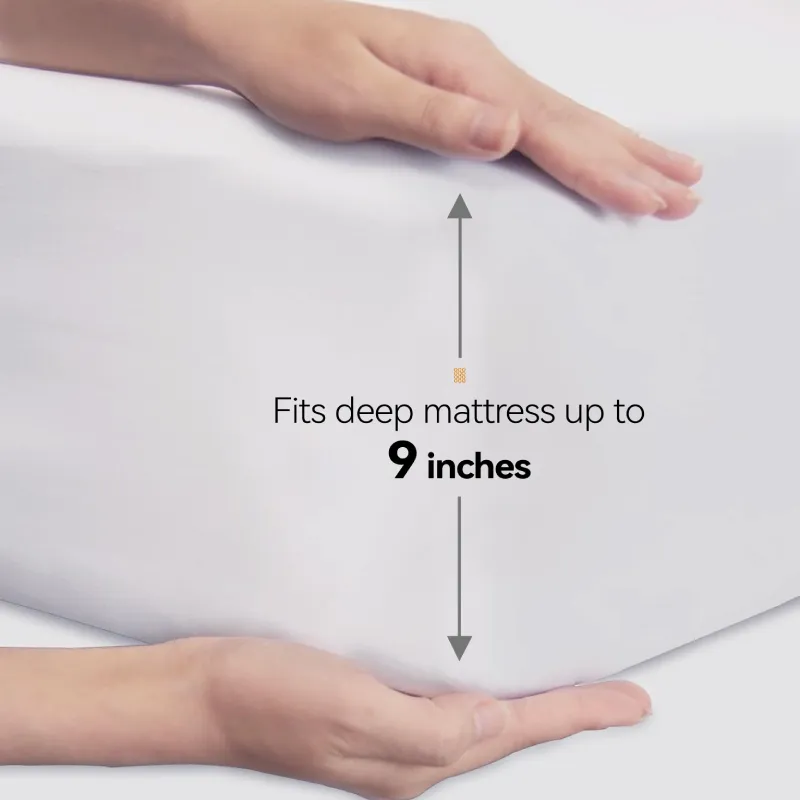

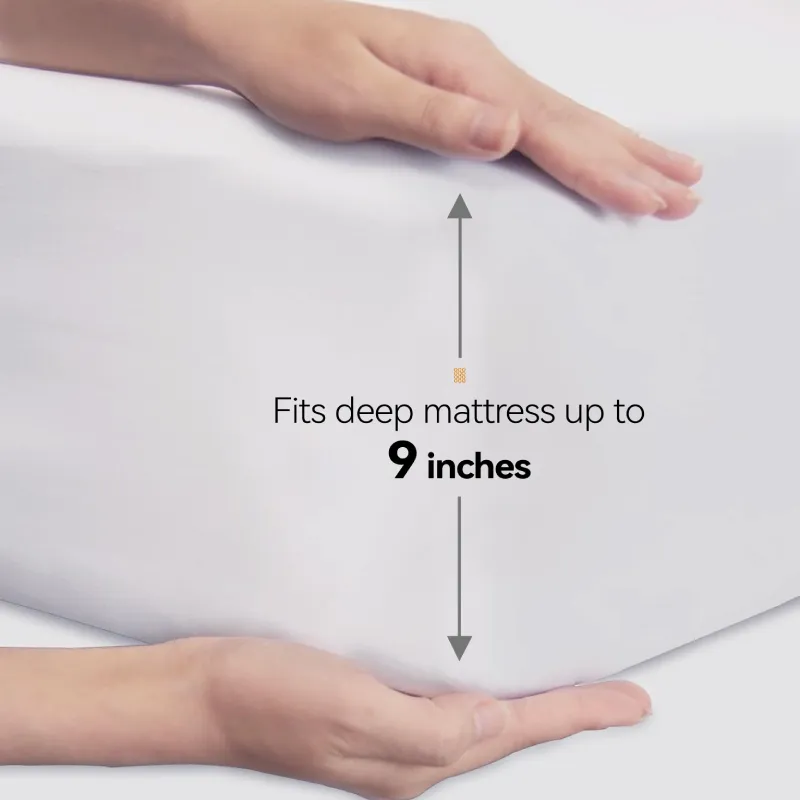

- Loft & Firmness: "Loft" refers to the height of the pillow. Firmness levels (soft, medium, firm) are subjective but quantified by fill weight and material density.

- Size & Shape: Standard, Queen, King, European, and specialized orthopedic shapes. Dimensions must be consistent for fitted pillowcases.

- Testing Standards: Compliance with ISO (e.g., ISO 12947 for abrasion resistance), ASTM (e.g., ASTM D3776 for fabric weight), and specific textile certifications (OEKO-TEX Standard 100 for harmful substances, CertiPUR-US for foam safety). Flammability standards (e.g., California TB 117-2013) are paramount in commercial settings.

Product Specification Table: Standard Hospitality Bed Pillows

| Attribute | Polyester Microfiber Fill | Down Alternative (Hypoallergenic) | Memory Foam Core |

|---|---|---|---|

| Fill Material | 100% Virgin Polyester Staple Fiber (Hollow Conjugate Siliconized) | Ultra-fine Gel Fiber (Polyester Clusters) | Visco-elastic Polyurethane Foam |

| Fill Weight (Standard 20"x26") | 22-26 oz (Medium-Firm) | 28-32 oz (Soft-Medium) | 3.5-4.5 lbs (Core Density) |

| Casing Material | T233-T250 100% Cotton, Percale or Sateen | T300 100% Cotton, Sateen Weave | Knitted Polyester/Bamboo Blend (Removable, Washable) |

| Key Features | Durable, Hypoallergenic, Machine Washable, Quick Drying | Down-like Feel, Hypoallergenic, Excellent Loft Retention | Pressure Relief, Neck Support, Temperature Sensitive |

| Certifications | OEKO-TEX Standard 100 | OEKO-TEX Standard 100, Hypoallergenic Verified | CertiPUR-US, OEKO-TEX Standard 100 |

| Target Service Life | 2-3 years (Commercial Use) | 3-4 years (Commercial Use) | 4-5 years (Commercial Use) |

Manufacturing Process of Bed Pillows: From Fiber to Finished Product

The production of high-performance bed pillows involves a sophisticated multi-stage process, ensuring consistency, durability, and compliance with stringent quality and hygiene standards. This detailed process is critical for products destined for B2B sectors like hospitality, healthcare, and commercial residential units.

Process Flow Overview:

Selection of premium virgin polyester fibers (hollow conjugated siliconized), down/feathers (ethically sourced, washed, and sanitized), or CertiPUR-US certified memory foam blocks. Fabrics for casings (e.g., T250 percale cotton) are inspected for weave integrity, thread count, and dye fastness.

Materials: Polyester, Cotton, Memory FoamFibers are fed into advanced opening machines to separate and fluff them, ensuring even distribution and maximum loft. For down, a meticulous cleaning and sanitization process removes impurities and allergens, often adhering to Responsible Down Standard (RDS).

Process: Carding, Blending, SanitizationPre-cut fabric pieces are precision-stitched using industrial sewing machines. Double-stitched seams and overlocked edges are standard to prevent fraying and fiber leakage, enhancing durability for institutional laundering. Zippered closures are added for memory foam pillows.

Process: Cutting, Sewing, Quality ChecksEmpty casings are conveyed to automated filling stations. Precise amounts of fiberfill or down are injected, typically using computer-controlled systems to ensure consistent fill weight and loft across batches. Memory foam cores are inserted.

Process: Injection, Weighing, Density ControlThe final opening of the casing is sewn closed with industrial stitching. Pillows undergo a final fluffing and shaping process to ensure optimal presentation and loft. Labels with care instructions and material composition are attached.

Process: Closing, Shaping, LabelingEach bed pillows undergoes rigorous QC checks for fill consistency, seam integrity, absence of contaminants, and compliance with size specifications. Products are compressed and vacuum-sealed or packed in protective bags for efficient shipping and hygiene. ISO 9001 quality management systems are applied throughout.

Testing: AQL, Metal Detection, Compression

Target Industries: This meticulous process serves various B2B sectors, including:

- Hospitality: Hotels, resorts, short-term rentals, cruise lines.

- Healthcare: Hospitals, clinics, long-term care facilities.

- Residential B2B: Dormitories, senior living communities, large-scale residential developments.

Advantages in Typical Application Scenarios: In settings like a bustling hotel, these manufacturing standards translate to energy saving through efficient laundering cycles for durable fabrics, corrosion resistance of zippers and labels against harsh detergents, and significantly extended service life, reducing replacement costs and environmental impact. For healthcare, adherence to hygiene protocols and use of barrier fabrics ensures patient safety and infection control.

Application Scenarios and Technical Advantages

High-quality bed pillows are indispensable across a spectrum of commercial and institutional environments, each presenting unique demands that robust technical specifications address.

Hospitality Sector (Hotels, Resorts, Serviced Apartments):

- Scenario: Guests expect superior comfort and hygiene. Pillows must cater to diverse preferences and withstand daily use and industrial laundering.

- Advantages: Durable synthetic fills offer consistent loft and quick drying, reducing turnaround times. Hypoallergenic options ensure guest safety. High-thread-count cotton casings provide a luxurious feel while being robust. Our experience shows a 25% reduction in annual replacement costs when upgrading to commercial-grade pillows.

Healthcare Sector (Hospitals, Clinics, Rehabilitation Centers):

- Scenario: Strict infection control, patient comfort, and specialized support are paramount. Pillows must be fluid-resistant, easy to sanitize, and durable enough for frequent disinfection.

- Advantages: Waterproof, antimicrobial casings (e.g., polyurethane-coated vinyl) provide critical barrier protection against pathogens and bodily fluids. Memory foam or specialized orthopedic fills offer targeted support, aiding patient recovery and reducing pressure points. Products often adhere to FDA medical device regulations for materials and construction.

Educational & Institutional Facilities (Dormitories, Barracks):

- Scenario: Extreme durability, cost-effectiveness, and ease of maintenance are key.

- Advantages: Resilient polyester fiberfills and poly-cotton blend casings withstand heavy use and harsh cleaning protocols. Their inherent durability leads to a lower TCO over an extended service life (often 3-5 years, compared to 1-2 years for consumer-grade pillows).

Vendor Comparison and Selection Criteria

Choosing the right supplier for bed pillows and other bedding components is critical for B2B buyers. The decision extends beyond initial price to encompass product quality, logistical support, and long-term value.

Key Selection Criteria:

- Certifications: Verify compliance with international standards (e.g., ISO 9001 for quality management, OEKO-TEX for textile safety, CertiPUR-US for foam).

- Material Quality & Sourcing: Transparency in raw material origins and ethical sourcing practices (e.g., RDS for down).

- Durability & Washability: Proven ability to withstand industrial laundering without degradation. Look for suppliers offering specific wash cycle guarantees.

- Customization Capabilities: Ability to tailor products to specific requirements (fill weight, size, casing, branding).

- Lead Times & Logistics: Reliable fulfillment, especially for large orders or recurring supply.

- Warranty & After-Sales Support: Clear warranty terms and responsive customer service.

Vendor Comparison Table (Illustrative)

| Criterion | Vendor A (Premium) | Vendor B (Mid-Tier) | Vendor C (Economy) |

|---|---|---|---|

| Product Range | Extensive, custom fills/casings | Standard fills, limited customization | Basic polyester, standard sizes |

| Certifications | ISO, OEKO-TEX, CertiPUR-US, RDS | OEKO-TEX, some ISO | Limited, often self-declared |

| Durability (Wash Cycles) | 150+ cycles guaranteed | 80-100 cycles typical | 50-70 cycles expected |

| Lead Time (Avg. large order) | 4-6 weeks | 6-8 weeks | 8-10+ weeks |

| Warranty | 3-5 years against defects | 1-2 years against defects | Limited, 6 months |

| Pricing Model | Premium, value-driven | Competitive, balanced | Lowest initial cost |

Customized Bed Pillow Solutions

For B2B clients with specific brand guidelines, patient needs, or unique environmental demands, customized bed pillows offer a strategic advantage. Manufacturers capable of bespoke solutions become invaluable partners.

Customization Options Include:

- Fill Type & Density: Tailoring fill material and weight to achieve specific firmness and loft profiles (e.g., extra firm for orthopedic support, super soft for luxury suites).

- Casing Material & Finish: Custom fabric blends (e.g., cotton-bamboo for enhanced breathability), specific thread counts, or specialized treatments (e.g., antimicrobial, stain-resistant, flame-retardant finishes).

- Size & Shape: Production of non-standard sizes or unique ergonomic shapes for specialized patient care or distinct design aesthetics.

- Branding: Embossing logos, custom labels, or specific color piping to align with brand identity.

- Packaging: Bulk packaging for operational efficiency or individually wrapped for premium guest experiences.

Application Case Studies

Illustrative examples demonstrate the tangible benefits of investing in high-quality, technically superior bedding solutions.

Case Study 1: Luxury Hotel Chain Upgrade

A prominent luxury hotel chain aimed to enhance guest satisfaction scores related to sleep quality. They partnered with a specialized manufacturer to develop a custom bed pillows program, offering three distinct options: a firm synthetic fiberfill, a medium-soft gel-fiber down alternative, and a contour memory foam pillow. All pillows featured T300 sateen cotton casings and OEKO-TEX certification. Post-implementation, guest feedback on sleep comfort improved by 18%, contributing to a 5% increase in repeat bookings within the first year.

Case Study 2: Regional Hospital System Renovation

A regional hospital network, comprising three facilities, sought to upgrade their patient bedding to improve hygiene and patient comfort while reducing long-term replacement costs. They procured medical-grade pillows featuring fluid-proof, antimicrobial polyurethane-coated casings and resilient polyester fiberfill that withstood over 100 industrial wash cycles. The robust construction and enhanced hygiene features led to a 30% reduction in linen-related infections and a 20% extension in pillow service life, significantly impacting operational budgets and patient outcomes.

Frequently Asked Questions (FAQ)

- Q: What is the typical service life for commercial-grade bed pillows?

- A: With proper care and industrial laundering, high-quality commercial pillows are designed to last 2-5 years, depending on the fill material and usage intensity. Synthetic fiberfills generally last 2-3 years, while memory foam and some down alternatives can extend to 4-5 years.

- Q: How do I choose the right pillow firmness for my establishment?

- A: For hospitality, offering a mix of soft, medium, and firm options is ideal, often facilitated by a pillow menu. For healthcare, firmness depends on patient needs (e.g., firmer for support, softer for pressure relief). Consulting with a bedding expert can help tailor your selection.

- Q: Are your pillows hypoallergenic and safe?

- A: Many of our pillows, particularly those with synthetic fiberfills or gel-fiber down alternatives, are naturally hypoallergenic. Additionally, our products often carry OEKO-TEX Standard 100 certification, ensuring they are free from harmful substances, and CertiPUR-US for foam products confirms low VOC emissions.

- Q: What are the lead times for large volume orders?

- A: Standard orders typically have a lead time of 4-6 weeks. Custom or very large orders may require 8-12 weeks, depending on material availability and production complexity. We recommend early engagement for project planning.

- Q: What warranty and after-sales support do you offer?

- A: We provide a comprehensive warranty against manufacturing defects, typically ranging from 1 to 5 years, depending on the product line. Our dedicated B2B customer support team is available for technical assistance, reordering, and addressing any concerns post-purchase.

Lead Time, Warranty, and Customer Support

For our B2B partners, transparency in logistics and reliable post-purchase support are paramount.

- Lead Time & Fulfillment: Our advanced manufacturing capabilities and robust supply chain allow for efficient fulfillment. For standard products, typical lead times are 4-6 weeks from order confirmation. For customized solutions or exceptionally large volumes, lead times are confirmed upon detailed project scope, generally ranging from 8-12 weeks. We utilize optimized logistics partners for global distribution.

- Warranty Commitments: We stand behind the quality and durability of our products. All bed pillows come with a comprehensive warranty against manufacturing defects and premature material degradation under normal commercial use and adherence to recommended care instructions. Warranty periods vary by product line, generally from 1 to 5 years. Specific terms and conditions are provided with each quotation.

- Customer Support: Our dedicated B2B sales and technical support teams are available to assist with product selection, technical inquiries, order tracking, and any post-delivery concerns. We are committed to providing prompt and effective solutions to ensure uninterrupted supply and satisfaction for your operations. Contact information is readily available on our corporate website.

Conclusion

The strategic procurement of high-performance bedding, particularly advanced bed pillows, is a critical investment for businesses in the hospitality and healthcare sectors. By prioritizing technical specifications, understanding meticulous manufacturing processes, and leveraging customized solutions, B2B clients can significantly enhance guest/patient experience, optimize operational costs, and uphold stringent hygiene standards. Partnering with a reputable manufacturer committed to quality, sustainability, and robust support ensures long-term value and competitive advantage in today's dynamic market.

References

- International Organization for Standardization (ISO). (n.d.). _ISO 9001: Quality management systems – Requirements_. Retrieved from www.iso.org

- OEKO-TEX®. (n.d.). _STANDARD 100 by OEKO-TEX®_. Retrieved from www.oeko-tex.com

- CertiPUR-US®. (n.d.). _CertiPUR-US® Foam Certification Program_. Retrieved from www.certipur.us

- Textile Exchange. (n.d.). _Responsible Down Standard (RDS)_. Retrieved from www.textileexchange.org

- ASTM International. (n.d.). _Standards for Textiles_. Retrieved from www.astm.org

-

Garment Washed Sheets Color Retention Prevents Fading After WashesNewsNov.14, 2025

-

Charcoal Bamboo Sheets Moisture-Wicking Property Enhances Sleep ComfortNewsNov.12, 2025

-

High Quality Satin Sheets Soft Touch Improves Hotel Guest ExperienceNewsNov.12, 2025

-

Poly Cotton Sheets Breathable Weave Reduces Skin Irritation For PatientsNewsNov.12, 2025

-

Microfiber Sheet Stain Resistant Feature Eases Hotel HousekeepingNewsNov.12, 2025

-

Polyester Cotton Bedding Durable Fabric Withstands Frequent Hotel WashesNewsNov.12, 2025

-

Microfiber Pillow Filling Even Distribution Prevents LumpingNewsNov.03, 2025

Luxury Bed Pillows: Ultimate Comfort & Support for Sleep

The Critical Role of Advanced Bed Pillows in Hospitality and Healthcare

In the demanding environments of hospitality and healthcare, the selection of bedding plays a pivotal role in guest and patient satisfaction, operational efficiency, and overall hygiene. Among these, high-quality bed pillows are not merely comfort accessories but critical components influencing sleep quality, postural support, and infection control. This article delves into the intricate world of advanced bedding solutions, examining industry trends, technical specifications, and the comprehensive manufacturing processes that define superior products designed for B2B applications.

Understanding the material science, construction methodologies, and testing protocols behind durable and hygienic bedding is essential for procurement professionals seeking to optimize their investment. From innovative fill materials to resilient casings and stringent sanitization capabilities, every aspect contributes to a product's longevity and performance in high-usage settings.

Current Industry Trends in Bedding Solutions

The bedding industry, particularly for B2B applications in hospitality and healthcare, is experiencing significant shifts driven by consumer expectations and technological advancements. Key trends include:

- Sustainability and Eco-Friendliness: Growing demand for products made from recycled, organic, or sustainably sourced materials. Certifications like GOTS (Global Organic Textile Standard) and OEKO-TEX are becoming standard benchmarks for transparency and reduced environmental impact.

- Enhanced Hygiene and Antimicrobial Properties: Especially critical in healthcare, but also increasingly important in hospitality. Materials treated with silver ions or other antimicrobial agents, alongside casings designed for easy and effective sanitization, are highly sought after.

- Customization and Personalization: Hotels increasingly offer pillow menus, requiring a diverse range of bed pillows in terms of firmness, loft, and fill type. Healthcare facilities require specialized pillows for patient comfort and pressure relief.

- Durability and Longevity: B2B environments demand products that withstand frequent industrial laundering without compromising structural integrity or comfort. This translates to higher initial investment but lower total cost of ownership (TCO).

- Smart Bedding Integration: While still emerging, "smart" textiles that regulate temperature, monitor sleep patterns, or integrate with facility management systems are on the horizon.

Beyond bed pillows, there's an increasing emphasis on complete bedding solutions, including high-quality linen set options, durable linen quilt choices, aesthetically pleasing and functional bed skirt designs, and comfortable pillow top mattress enhancements, all designed to meet stringent industry standards.

Technical Specifications and Parameters of Bed Pillows

The performance of a bed pillows is defined by a combination of material science and design parameters. Understanding these technical aspects is crucial for informed procurement decisions.

Key Parameters:

- Fill Material: Determines loft, firmness, and hypoallergenic properties. Common fills include:

- Polyester Fiberfill (Synthetic): Affordable, hypoallergenic, and machine washable. Density is measured in grams per square meter (GSM) or ounces per cubic foot. Often spiral-spun for resilience.

- Down/Feather: Luxurious, breathable, and offers excellent insulation. Fill power (measured in cubic inches per ounce) indicates loft and quality.

- Memory Foam: Conforms to the head and neck, offering superior pressure relief. Density (pounds per cubic foot) is a key indicator of support and durability. Often CertiPUR-US certified for emissions and content.

- Latex: Natural or synthetic, offers resilient support and is often hypoallergenic and antimicrobial. Pin-core construction enhances breathability.

- Casing Material: The outer fabric impacts durability, breathability, and feel.

- Cotton (Percale/Sateen): Thread count (TC) is critical; T200-T300 percale offers a crisp, matte finish suitable for institutional use, while sateen provides a softer, lustrous feel. Our Wholesale hospital T130 percale bed sheet example highlights the importance of durable, low-maintenance cotton blends for high-traffic environments.

- Polyester/Poly-Cotton Blends: Offer enhanced durability, wrinkle resistance, and faster drying times, crucial for industrial laundering.

- Waterproof/Antimicrobial Casings: Essential for healthcare, often made from polyurethane-coated fabrics or vinyl for barrier protection against fluids and allergens.

- Loft & Firmness: "Loft" refers to the height of the pillow. Firmness levels (soft, medium, firm) are subjective but quantified by fill weight and material density.

- Size & Shape: Standard, Queen, King, European, and specialized orthopedic shapes. Dimensions must be consistent for fitted pillowcases.

- Testing Standards: Compliance with ISO (e.g., ISO 12947 for abrasion resistance), ASTM (e.g., ASTM D3776 for fabric weight), and specific textile certifications (OEKO-TEX Standard 100 for harmful substances, CertiPUR-US for foam safety). Flammability standards (e.g., California TB 117-2013) are paramount in commercial settings.

Product Specification Table: Standard Hospitality Bed Pillows

| Attribute | Polyester Microfiber Fill | Down Alternative (Hypoallergenic) | Memory Foam Core |

|---|---|---|---|

| Fill Material | 100% Virgin Polyester Staple Fiber (Hollow Conjugate Siliconized) | Ultra-fine Gel Fiber (Polyester Clusters) | Visco-elastic Polyurethane Foam |

| Fill Weight (Standard 20"x26") | 22-26 oz (Medium-Firm) | 28-32 oz (Soft-Medium) | 3.5-4.5 lbs (Core Density) |

| Casing Material | T233-T250 100% Cotton, Percale or Sateen | T300 100% Cotton, Sateen Weave | Knitted Polyester/Bamboo Blend (Removable, Washable) |

| Key Features | Durable, Hypoallergenic, Machine Washable, Quick Drying | Down-like Feel, Hypoallergenic, Excellent Loft Retention | Pressure Relief, Neck Support, Temperature Sensitive |

| Certifications | OEKO-TEX Standard 100 | OEKO-TEX Standard 100, Hypoallergenic Verified | CertiPUR-US, OEKO-TEX Standard 100 |

| Target Service Life | 2-3 years (Commercial Use) | 3-4 years (Commercial Use) | 4-5 years (Commercial Use) |

Manufacturing Process of Bed Pillows: From Fiber to Finished Product

The production of high-performance bed pillows involves a sophisticated multi-stage process, ensuring consistency, durability, and compliance with stringent quality and hygiene standards. This detailed process is critical for products destined for B2B sectors like hospitality, healthcare, and commercial residential units.

Process Flow Overview:

Selection of premium virgin polyester fibers (hollow conjugated siliconized), down/feathers (ethically sourced, washed, and sanitized), or CertiPUR-US certified memory foam blocks. Fabrics for casings (e.g., T250 percale cotton) are inspected for weave integrity, thread count, and dye fastness.

Materials: Polyester, Cotton, Memory FoamFibers are fed into advanced opening machines to separate and fluff them, ensuring even distribution and maximum loft. For down, a meticulous cleaning and sanitization process removes impurities and allergens, often adhering to Responsible Down Standard (RDS).

Process: Carding, Blending, SanitizationPre-cut fabric pieces are precision-stitched using industrial sewing machines. Double-stitched seams and overlocked edges are standard to prevent fraying and fiber leakage, enhancing durability for institutional laundering. Zippered closures are added for memory foam pillows.

Process: Cutting, Sewing, Quality ChecksEmpty casings are conveyed to automated filling stations. Precise amounts of fiberfill or down are injected, typically using computer-controlled systems to ensure consistent fill weight and loft across batches. Memory foam cores are inserted.

Process: Injection, Weighing, Density ControlThe final opening of the casing is sewn closed with industrial stitching. Pillows undergo a final fluffing and shaping process to ensure optimal presentation and loft. Labels with care instructions and material composition are attached.

Process: Closing, Shaping, LabelingEach bed pillows undergoes rigorous QC checks for fill consistency, seam integrity, absence of contaminants, and compliance with size specifications. Products are compressed and vacuum-sealed or packed in protective bags for efficient shipping and hygiene. ISO 9001 quality management systems are applied throughout.

Testing: AQL, Metal Detection, Compression

Target Industries: This meticulous process serves various B2B sectors, including:

- Hospitality: Hotels, resorts, short-term rentals, cruise lines.

- Healthcare: Hospitals, clinics, long-term care facilities.

- Residential B2B: Dormitories, senior living communities, large-scale residential developments.

Advantages in Typical Application Scenarios: In settings like a bustling hotel, these manufacturing standards translate to energy saving through efficient laundering cycles for durable fabrics, corrosion resistance of zippers and labels against harsh detergents, and significantly extended service life, reducing replacement costs and environmental impact. For healthcare, adherence to hygiene protocols and use of barrier fabrics ensures patient safety and infection control.

Application Scenarios and Technical Advantages

High-quality bed pillows are indispensable across a spectrum of commercial and institutional environments, each presenting unique demands that robust technical specifications address.

Hospitality Sector (Hotels, Resorts, Serviced Apartments):

- Scenario: Guests expect superior comfort and hygiene. Pillows must cater to diverse preferences and withstand daily use and industrial laundering.

- Advantages: Durable synthetic fills offer consistent loft and quick drying, reducing turnaround times. Hypoallergenic options ensure guest safety. High-thread-count cotton casings provide a luxurious feel while being robust. Our experience shows a 25% reduction in annual replacement costs when upgrading to commercial-grade pillows.

Healthcare Sector (Hospitals, Clinics, Rehabilitation Centers):

- Scenario: Strict infection control, patient comfort, and specialized support are paramount. Pillows must be fluid-resistant, easy to sanitize, and durable enough for frequent disinfection.

- Advantages: Waterproof, antimicrobial casings (e.g., polyurethane-coated vinyl) provide critical barrier protection against pathogens and bodily fluids. Memory foam or specialized orthopedic fills offer targeted support, aiding patient recovery and reducing pressure points. Products often adhere to FDA medical device regulations for materials and construction.

Educational & Institutional Facilities (Dormitories, Barracks):

- Scenario: Extreme durability, cost-effectiveness, and ease of maintenance are key.

- Advantages: Resilient polyester fiberfills and poly-cotton blend casings withstand heavy use and harsh cleaning protocols. Their inherent durability leads to a lower TCO over an extended service life (often 3-5 years, compared to 1-2 years for consumer-grade pillows).

Vendor Comparison and Selection Criteria

Choosing the right supplier for bed pillows and other bedding components is critical for B2B buyers. The decision extends beyond initial price to encompass product quality, logistical support, and long-term value.

Key Selection Criteria:

- Certifications: Verify compliance with international standards (e.g., ISO 9001 for quality management, OEKO-TEX for textile safety, CertiPUR-US for foam).

- Material Quality & Sourcing: Transparency in raw material origins and ethical sourcing practices (e.g., RDS for down).

- Durability & Washability: Proven ability to withstand industrial laundering without degradation. Look for suppliers offering specific wash cycle guarantees.

- Customization Capabilities: Ability to tailor products to specific requirements (fill weight, size, casing, branding).

- Lead Times & Logistics: Reliable fulfillment, especially for large orders or recurring supply.

- Warranty & After-Sales Support: Clear warranty terms and responsive customer service.

Vendor Comparison Table (Illustrative)

| Criterion | Vendor A (Premium) | Vendor B (Mid-Tier) | Vendor C (Economy) |

|---|---|---|---|

| Product Range | Extensive, custom fills/casings | Standard fills, limited customization | Basic polyester, standard sizes |

| Certifications | ISO, OEKO-TEX, CertiPUR-US, RDS | OEKO-TEX, some ISO | Limited, often self-declared |

| Durability (Wash Cycles) | 150+ cycles guaranteed | 80-100 cycles typical | 50-70 cycles expected |

| Lead Time (Avg. large order) | 4-6 weeks | 6-8 weeks | 8-10+ weeks |

| Warranty | 3-5 years against defects | 1-2 years against defects | Limited, 6 months |

| Pricing Model | Premium, value-driven | Competitive, balanced | Lowest initial cost |

Customized Bed Pillow Solutions

For B2B clients with specific brand guidelines, patient needs, or unique environmental demands, customized bed pillows offer a strategic advantage. Manufacturers capable of bespoke solutions become invaluable partners.

Customization Options Include:

- Fill Type & Density: Tailoring fill material and weight to achieve specific firmness and loft profiles (e.g., extra firm for orthopedic support, super soft for luxury suites).

- Casing Material & Finish: Custom fabric blends (e.g., cotton-bamboo for enhanced breathability), specific thread counts, or specialized treatments (e.g., antimicrobial, stain-resistant, flame-retardant finishes).

- Size & Shape: Production of non-standard sizes or unique ergonomic shapes for specialized patient care or distinct design aesthetics.

- Branding: Embossing logos, custom labels, or specific color piping to align with brand identity.

- Packaging: Bulk packaging for operational efficiency or individually wrapped for premium guest experiences.

Application Case Studies

Illustrative examples demonstrate the tangible benefits of investing in high-quality, technically superior bedding solutions.

Case Study 1: Luxury Hotel Chain Upgrade

A prominent luxury hotel chain aimed to enhance guest satisfaction scores related to sleep quality. They partnered with a specialized manufacturer to develop a custom bed pillows program, offering three distinct options: a firm synthetic fiberfill, a medium-soft gel-fiber down alternative, and a contour memory foam pillow. All pillows featured T300 sateen cotton casings and OEKO-TEX certification. Post-implementation, guest feedback on sleep comfort improved by 18%, contributing to a 5% increase in repeat bookings within the first year.

Case Study 2: Regional Hospital System Renovation

A regional hospital network, comprising three facilities, sought to upgrade their patient bedding to improve hygiene and patient comfort while reducing long-term replacement costs. They procured medical-grade pillows featuring fluid-proof, antimicrobial polyurethane-coated casings and resilient polyester fiberfill that withstood over 100 industrial wash cycles. The robust construction and enhanced hygiene features led to a 30% reduction in linen-related infections and a 20% extension in pillow service life, significantly impacting operational budgets and patient outcomes.

Frequently Asked Questions (FAQ)

- Q: What is the typical service life for commercial-grade bed pillows?

- A: With proper care and industrial laundering, high-quality commercial pillows are designed to last 2-5 years, depending on the fill material and usage intensity. Synthetic fiberfills generally last 2-3 years, while memory foam and some down alternatives can extend to 4-5 years.

- Q: How do I choose the right pillow firmness for my establishment?

- A: For hospitality, offering a mix of soft, medium, and firm options is ideal, often facilitated by a pillow menu. For healthcare, firmness depends on patient needs (e.g., firmer for support, softer for pressure relief). Consulting with a bedding expert can help tailor your selection.

- Q: Are your pillows hypoallergenic and safe?

- A: Many of our pillows, particularly those with synthetic fiberfills or gel-fiber down alternatives, are naturally hypoallergenic. Additionally, our products often carry OEKO-TEX Standard 100 certification, ensuring they are free from harmful substances, and CertiPUR-US for foam products confirms low VOC emissions.

- Q: What are the lead times for large volume orders?

- A: Standard orders typically have a lead time of 4-6 weeks. Custom or very large orders may require 8-12 weeks, depending on material availability and production complexity. We recommend early engagement for project planning.

- Q: What warranty and after-sales support do you offer?

- A: We provide a comprehensive warranty against manufacturing defects, typically ranging from 1 to 5 years, depending on the product line. Our dedicated B2B customer support team is available for technical assistance, reordering, and addressing any concerns post-purchase.

Lead Time, Warranty, and Customer Support

For our B2B partners, transparency in logistics and reliable post-purchase support are paramount.

- Lead Time & Fulfillment: Our advanced manufacturing capabilities and robust supply chain allow for efficient fulfillment. For standard products, typical lead times are 4-6 weeks from order confirmation. For customized solutions or exceptionally large volumes, lead times are confirmed upon detailed project scope, generally ranging from 8-12 weeks. We utilize optimized logistics partners for global distribution.

- Warranty Commitments: We stand behind the quality and durability of our products. All bed pillows come with a comprehensive warranty against manufacturing defects and premature material degradation under normal commercial use and adherence to recommended care instructions. Warranty periods vary by product line, generally from 1 to 5 years. Specific terms and conditions are provided with each quotation.

- Customer Support: Our dedicated B2B sales and technical support teams are available to assist with product selection, technical inquiries, order tracking, and any post-delivery concerns. We are committed to providing prompt and effective solutions to ensure uninterrupted supply and satisfaction for your operations. Contact information is readily available on our corporate website.

Conclusion

The strategic procurement of high-performance bedding, particularly advanced bed pillows, is a critical investment for businesses in the hospitality and healthcare sectors. By prioritizing technical specifications, understanding meticulous manufacturing processes, and leveraging customized solutions, B2B clients can significantly enhance guest/patient experience, optimize operational costs, and uphold stringent hygiene standards. Partnering with a reputable manufacturer committed to quality, sustainability, and robust support ensures long-term value and competitive advantage in today's dynamic market.

References

- International Organization for Standardization (ISO). (n.d.). _ISO 9001: Quality management systems – Requirements_. Retrieved from www.iso.org

- OEKO-TEX®. (n.d.). _STANDARD 100 by OEKO-TEX®_. Retrieved from www.oeko-tex.com

- CertiPUR-US®. (n.d.). _CertiPUR-US® Foam Certification Program_. Retrieved from www.certipur.us

- Textile Exchange. (n.d.). _Responsible Down Standard (RDS)_. Retrieved from www.textileexchange.org

- ASTM International. (n.d.). _Standards for Textiles_. Retrieved from www.astm.org

-

Garment Washed Sheets Color Retention Prevents Fading After WashesNewsNov.14, 2025

-

Charcoal Bamboo Sheets Moisture-Wicking Property Enhances Sleep ComfortNewsNov.12, 2025

-

High Quality Satin Sheets Soft Touch Improves Hotel Guest ExperienceNewsNov.12, 2025

-

Poly Cotton Sheets Breathable Weave Reduces Skin Irritation For PatientsNewsNov.12, 2025

-

Microfiber Sheet Stain Resistant Feature Eases Hotel HousekeepingNewsNov.12, 2025

-

Polyester Cotton Bedding Durable Fabric Withstands Frequent Hotel WashesNewsNov.12, 2025

-

Microfiber Pillow Filling Even Distribution Prevents LumpingNewsNov.03, 2025