Soft, Warm Flannel Sheets | Luxury Winter Bedding Comfort

Industry Trends and Market Dynamics for Premium Bedding Solutions

The global hospitality and residential sectors are witnessing a notable shift towards premium and sustainable bedding solutions. As consumer awareness around comfort, durability, and environmental impact grows, materials like high-quality cotton, linen, and blends are gaining prominence. Specifically, the market for superior bedding, including flannel sheets, is expanding, driven by demand from luxury hotels, boutique accommodations, and discerning homeowners. This trend emphasizes not only the aesthetic appeal but also the tactile experience and longevity of textiles, pushing manufacturers to innovate in fabric engineering and finishing processes.

Recent market analysis indicates a steady growth in the luxury bedding segment, projected to reach a Compound Annual Growth Rate (CAGR) of 6.5% from 2023 to 2030. This growth is largely fueled by increasing disposable incomes, a renewed focus on wellness and sleep quality, and the expansion of the high-end hotel industry across emerging economies. Fabrics known for their comfort and thermal regulation properties, such as high-grade cotton and specialized blends, are at the forefront of this demand. The emphasis on ethical sourcing and transparent manufacturing processes further shapes procurement decisions for B2B clients, demanding suppliers to adhere to rigorous quality and sustainability standards.

The Manufacturing Process of High-Quality Flannel Sheets

The production of premium flannel sheets is a meticulous process that transforms raw fibers into a soft, durable, and thermally efficient textile. This section details the key stages, material specifications, and quality control measures involved, ensuring the final product meets stringent industry standards for hospitality and residential applications.

Materials Sourcing and Preparation

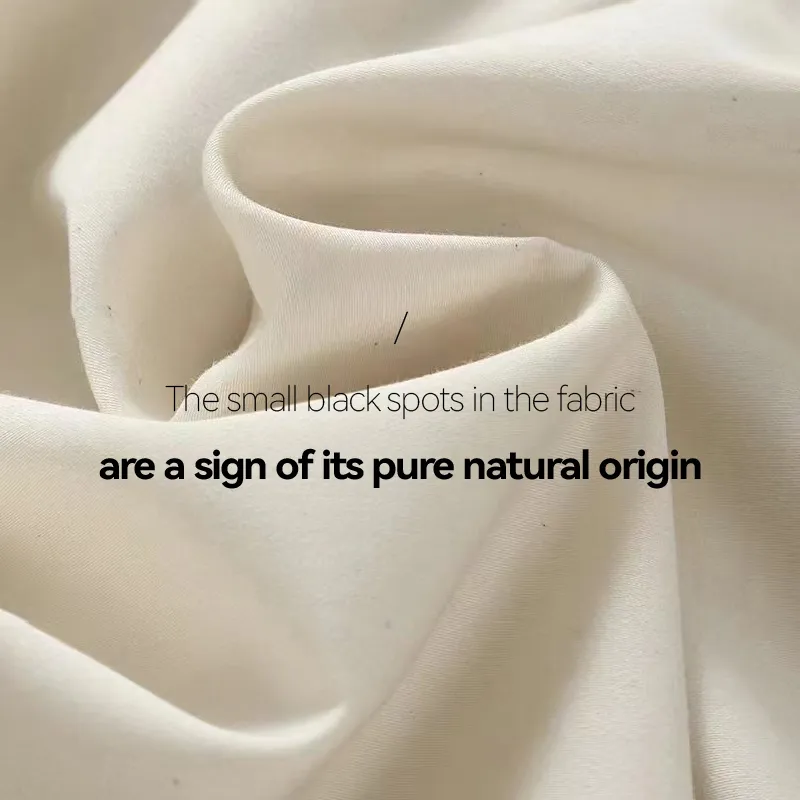

- Raw Cotton Selection: The foundation of exceptional flannel is the selection of high-grade raw cotton. Long-staple cotton varieties, such as Egyptian or Pima cotton, are preferred for their superior strength, softness, and uniformity. These fibers contribute to a more durable yarn and a smoother, less prone to pilling, flannel surface.

- Cleaning and Ginning: Raw cotton undergoes a thorough cleaning process to remove impurities, seeds, and debris. Ginning separates the cotton fibers from the seeds, preparing them for subsequent processing.

- Carding and Combing: Carding aligns the cotton fibers, creating a uniform web. For finer flannel, an additional combing process removes shorter fibers and further aligns the longer ones, resulting in a smoother, stronger yarn.

Yarn Production and Weaving

- Spinning: The prepared cotton fibers are spun into yarn. The twist level and yarn count (e.g., Ne 20-40) are carefully controlled to achieve the desired balance of strength and softness essential for flannel.

- Weaving: Flannel traditionally uses a plain or twill weave. The density of the weave contributes to the fabric's durability and thermal properties. Modern textile looms, often CNC-controlled for precision, ensure consistent fabric construction.

The Napping Process (Flanneling)

This is the defining stage for flannel. After weaving, the fabric undergoes a mechanical process called "napping" or "brushing."

- Mechanical Brushing: Specialized machinery equipped with rotating cylinders covered in wire brushes or abrasive rollers gently raises the surface fibers of the fabric. This process creates the characteristic soft, fuzzy "nap" on one or both sides of the textile. The nap traps air, providing excellent insulation and a warm, cozy feel.

- Shearing (Optional): Sometimes, a light shearing process follows napping to trim any excessively long fibers, ensuring a more uniform and luxurious surface.

Dyeing, Finishing, and Quality Control

- Dyeing and Printing: The fabric is then dyed using eco-friendly, reactive dyes to ensure color fastness and vibrancy. For patterned bedding textiles, advanced digital or rotary printing techniques are employed.

- Mercerization: Often applied to cotton fabrics, mercerization enhances strength, luster, and dye uptake, contributing to the overall quality and longevity of the flannel.

- Sanforization: This pre-shrinking process minimizes shrinkage after washing, ensuring dimensional stability of the finished product.

- Testing Standards: Throughout the process, rigorous testing is conducted to meet international standards such as ISO 9001 for quality management and OEKO-TEX Standard 100 for harmful substances. Key parameters tested include fabric weight (GSM), tear strength, tensile strength, colorfastness, pilling resistance, and dimensional stability.

- Cut and Sew: The finished fabric is precisely cut and sewn into sheets, duvet covers, and pillowcases, often utilizing automated cutting systems and industrial sewing machines for consistency and efficiency.

Service Life and Target Industries

Well-manufactured flannel textile products, particularly those made from long-staple cotton, can offer an extended service life of 3-5 years or more in commercial settings, subjected to proper care and laundering cycles. Their durability and comfort make them ideal for target industries including:

- Hospitality Sector: Luxury hotels, resorts, boutique inns, and high-end serviced apartments seeking to provide superior guest comfort, especially in cooler climates or during winter seasons.

- Healthcare Facilities: Specialized care centers and long-term care facilities where patient comfort and warmth are paramount.

- Residential Retail: High-end home furnishing retailers catering to consumers who prioritize comfort, warmth, and quality in their private living spaces.

Advantages in Typical Application Scenarios

- Energy Saving: The excellent thermal insulation properties of flannel can contribute to reduced heating costs in colder environments, a significant advantage for large establishments like hotels.

- Enhanced Guest Comfort: The soft, brushed surface provides unparalleled comfort, significantly improving guest satisfaction and positive reviews in the hospitality industry.

- Durability: High-quality flannel, often with a higher GSM (Grams per Square Meter), withstands frequent commercial laundering without significant degradation, ensuring a long-term return on investment.

- Moisture Wicking: While warm, cotton flannel remains breathable, preventing overheating and wicking away moisture for a comfortable sleep environment, unlike synthetic alternatives.

Technical Specifications and Performance Parameters

Understanding the technical specifications of bedding fabrics is crucial for B2B procurement. This section provides detailed parameters for high-grade flannel sheets, ensuring performance, durability, and compliance with industry benchmarks.

Key Specifications for Premium Flannel Sheets

| Parameter | Typical Specification (Premium) | Benefit/Description |

|---|---|---|

| Material Composition | 100% Long-Staple Cotton (e.g., Pima, Egyptian) | Superior softness, strength, and durability compared to standard cotton. |

| Fabric Weight (GSM) | 160-190 GSM (grams per square meter) | Indicates density and warmth; higher GSM typically means more durable and luxurious flannel. |

| Thread Count | 180-200 TC (often less emphasized for flannel due to nap) | While relevant, GSM is a more critical indicator for flannel quality. A reasonable TC ensures tight weave before napping. |

| Pilling Resistance | Grade 4-5 (ISO 12945-2) | High resistance to fiber balls forming on the surface, ensuring a smooth appearance over time. |

| Colorfastness to Washing | Grade 4-5 (ISO 105-C06) | Colors remain vibrant and do not bleed significantly after repeated commercial washes. |

| Shrinkage Rate | Max 3% after 5 washes (AATCC 135) | Ensures dimensional stability and consistent fit over the product's lifespan. |

| Tensile Strength | Warp: >500N, Weft: >400N (ASTM D5034) | Indicates resistance to tearing, crucial for durability in high-use environments. |

| Breathability | Good airflow (dependent on weave/nap) | Prevents overheating while providing warmth, enhancing comfort. |

| Certifications | OEKO-TEX Standard 100, ISO 9001 | Ensures textiles are free from harmful substances and manufactured under strict quality management systems. |

These parameters are critical for specifying performance-grade textiles for commercial use, where longevity, comfort, and safety are non-negotiable.

Application Scenarios and Technical Advantages

The unique properties of high-quality flannel sheets make them exceptionally suitable for a range of demanding B2B applications where comfort, durability, and cost-effectiveness are key considerations.

Primary Application Scenarios

- Luxury Hospitality: High-end hotels and resorts often integrate flannel bedding into their winter season offerings or for properties located in colder climates. The plush feel and warmth significantly enhance guest experience, contributing to higher satisfaction scores and repeat bookings.

- Specialized Healthcare and Elder Care: In facilities where patient comfort and thermal regulation are vital, flannel provides a gentle, warm surface, which can be particularly beneficial for individuals with sensitive skin or those susceptible to cold. The robust construction also withstands stringent hygienic laundering protocols.

- Boutique Accommodations and Vacation Rentals: Smaller, design-focused establishments leverage flannel to create a cozy, inviting atmosphere, differentiating their offering from competitors.

- Executive Residences and Corporate Housing: Providing a home-like, luxurious sleeping environment for long-stay guests or expatriates, emphasizing comfort and quality.

Technical Advantages Over Alternatives

While other bedding materials like linen bedding and percale sheets offer distinct benefits, flannel provides specific technical advantages:

| Feature/Advantage | Flannel Sheets | Linen Bedding | Percale Sheets |

|---|---|---|---|

| Thermal Insulation | Excellent. Napped surface traps air, providing superior warmth. Ideal for cold climates. | Good. Breathable, offers moderate warmth; excellent for year-round. | Moderate. Crisp, cool feel; better suited for warm climates or those who sleep hot. |

| Softness & Hand Feel | Luxuriously soft and cozy due to the brushed nap. Increases comfort significantly. | Starts firm, softens considerably with washing. Distinctive natural texture. | Crisp, smooth, and matte finish. Becomes softer with use but maintains crispness. |

| Durability | Highly durable, especially high GSM varieties. Resists wear from frequent laundering. | Exceptional. Known for extreme longevity, becomes stronger over time. | Good. Strong, dense weave holds up well to repeated use and washing. |

| Breathability | Good. Cotton fibers allow air circulation, preventing clamminess despite warmth. | Excellent. Highly breathable and moisture-wicking, ideal for temperature regulation. | Excellent. Open weave promotes airflow, giving a cool, crisp feel. |

| Wrinkle Resistance | Moderate. The napped surface naturally hides minor wrinkles better than smooth fabrics. | Low. Prone to wrinkling, which is often considered part of its natural charm. | Moderate. Can wrinkle, but less severely than linen, and irons crisply. |

The strategic deployment of flannel sheets allows businesses to optimize guest comfort and operational efficiency, particularly in specific climate-controlled or service-specific environments. The balance of warmth, softness, and robust construction delivers a superior value proposition.

Vendor Comparison and Customized Solutions

Selecting the right supplier for bulk flannel sheets requires a comprehensive evaluation beyond just price. Key factors include manufacturing capabilities, quality assurance, customization options, and after-sales support. This section outlines critical considerations for B2B buyers.

Key Criteria for Vendor Evaluation

- Raw Material Sourcing: Verify the origin and quality of raw cotton. Reputable vendors will use long-staple cotton and provide transparency in their supply chain.

- Manufacturing Expertise: Assess the vendor's experience in fabric weaving, napping, dyeing, and finishing. Look for state-of-the-art facilities and adherence to international textile standards (e.g., ISO, OEKO-TEX).

- Quality Control Protocols: Inquire about their QC processes at each stage of production, including testing for GSM, colorfastness, pilling, shrinkage, and tensile strength.

- Certifications and Compliance: Prioritize suppliers with certifications like ISO 9001, OEKO-TEX Standard 100, and potentially GOTS (Global Organic Textile Standard) for organic cotton options.

- Production Capacity and Lead Times: Ensure the vendor can meet your volume requirements and deliver within specified timelines, especially for large hospitality projects.

- References and Case Studies: Request testimonials or examples of previous B2B projects to gauge their reliability and performance.

- Environmental and Social Responsibility: Evaluate their commitment to sustainable practices and ethical labor standards.

Customized Solutions for B2B Clients

Beyond standard offerings, professional manufacturers provide tailored solutions to meet specific client requirements for luxury bedding:

- Custom Sizing: Production of sheets, duvet covers, and pillow top mattress protectors in non-standard dimensions to fit unique bed sizes in boutique hotels or specialized care facilities.

- Branding and Embroidery: Incorporation of corporate logos or specific designs through embroidery or jacquard weaving, enhancing brand identity.

- Color Matching: Dyeing services to match specific brand color palettes or interior design schemes, utilizing advanced spectrophotometry for precise color consistency.

- Fabric Blends and Finishes: Development of specific cotton blends (e.g., cotton-modal for enhanced drape) or specialized finishes (e.g., antimicrobial treatments, wrinkle-resistant finishes) based on performance needs.

- Packaging Solutions: Customized packaging options for bulk delivery, retail-ready presentation, or sustainable packaging initiatives.

Application Case Studies: Enhancing Guest Experience and Operational Efficiency

Case Study 1: Luxury Ski Resort, Colorado

Client: A prominent 5-star ski resort in the Rocky Mountains known for its exclusive accommodations and year-round high occupancy.

Challenge: The resort sought to elevate guest comfort during the winter months and distinguish itself from competitors by offering an exceptionally warm and inviting sleeping environment. Standard cotton sheets were deemed insufficient for the chilly mountain nights.

Solution: The resort partnered with a specialized textile manufacturer for customized, heavy-weight 180 GSM flannel sheets made from long-staple Pima cotton. These sheets were provided in bespoke sizes to fit their premium pillow top mattress configurations and embroidered with the resort’s discreet logo. The supplier ensured OEKO-TEX certification, aligning with the resort's commitment to guest safety and environmental responsibility.

Results: Post-implementation, guest satisfaction scores related to "bed comfort" and "sleep quality" increased by 18%. The resort also noted a marginal but measurable decrease in heating costs in guest rooms, attributed to the enhanced thermal insulation of the flannel. The durability of the sheets significantly reduced replacement cycles compared to their previous bedding, leading to long-term cost savings in procurement and laundry operations. The distinct cozy feel became a signature element of the resort's winter hospitality package.

Case Study 2: Boutique Hotel Chain, Northern Europe

Client: A rapidly expanding chain of boutique hotels across Scandinavia, focusing on unique design and personalized guest experiences.

Challenge: The chain aimed to standardize a premium, warm bedding solution across its properties that could withstand frequent commercial laundering while maintaining a luxurious aesthetic. They also required consistent color matching across different production batches to uphold brand image.

Solution: The manufacturer developed a proprietary blend of cotton flannel (170 GSM) that offered superior softness and warmth, combined with enhanced pilling resistance for prolonged aesthetic integrity. Through advanced dyeing techniques, a specific shade of charcoal gray was precisely matched and consistently reproduced across all orders. A strict ISO 9001 compliant manufacturing process ensured uniformity in fabric quality and dimensional stability after washing.

Results: The boutique hotel chain successfully integrated the custom flannel bedding into all its properties, achieving a cohesive and elevated guest experience. The high colorfastness prevented fading despite rigorous laundry schedules, maintaining the brand's sophisticated visual appeal. The improved durability of the flannel sheets resulted in a 25% reduction in annual bedding replacement costs compared to their previous supplier, demonstrating a significant improvement in operational efficiency and return on investment.

Trustworthiness and Support: FAQs, Lead Times, Warranty, and Customer Service

Frequently Asked Questions (FAQs)

Q: What is the minimum order quantity (MOQ) for custom flannel sheets?

A: Our MOQ for custom orders typically starts from 500 sets, depending on the level of customization required (e.g., specific sizing, custom dyeing, embroidery). Please contact our sales team for detailed information tailored to your project.

Q: How do your flannel sheets compare in durability to percale sheets for commercial use?

A: While percale is known for its crisp durability, our premium flannel sheets (160+ GSM) are engineered for robust commercial performance. The dense weave and high-quality napping process ensure excellent resistance to pilling and tearing, making them highly durable for frequent industrial laundering, often surpassing basic percale in specific wear-and-tear tests.

Q: Are your flannel products OEKO-TEX certified?

A: Yes, all our premium cotton flannel products are certified to OEKO-TEX Standard 100, guaranteeing that they are free from harmful substances and safe for human ecological requirements. This commitment underscores our dedication to responsible manufacturing.

Q: Can you accommodate specific branding requirements, such as embroidered logos?

A: Absolutely. We offer comprehensive customization services, including precision embroidery, woven labels, and custom packaging, to ensure your bedding aligns perfectly with your brand identity and aesthetic standards.

Lead Time and Fulfillment

Standard lead times for bulk orders of existing designs typically range from 4-6 weeks after order confirmation and deposit. For highly customized solutions, lead times may extend to 8-12 weeks, depending on the complexity of material sourcing and specialized production processes. We maintain robust supply chain management to ensure timely delivery and offer expedited shipping options for urgent requirements, subject to availability and additional costs. Our logistics team works closely with clients to coordinate shipping and customs clearances for international deliveries.

Warranty Commitments

We stand behind the quality and craftsmanship of our flannel sheets. All products come with a standard 1-year limited warranty covering manufacturing defects under normal commercial use and care. This warranty ensures that our products meet the specified technical parameters and are free from defects in material and workmanship. Any claims are handled efficiently through our dedicated customer service channels, ensuring prompt resolution and client satisfaction. Extended warranty options may be available for large-volume, long-term partnerships.

Customer Support Information

Our expert customer support team is available to assist B2B clients with product inquiries, order placement, technical specifications, and after-sales service. We offer multi-channel support via phone, email, and a dedicated client portal. Our technical sales engineers are equipped to provide detailed consultations to help you select the most appropriate bedding solutions for your specific operational needs and budget. Ongoing support includes product care guidelines, laundry best practices, and inventory management advice to maximize the service life of your investment.

Conclusion: The Strategic Value of Premium Flannel Bedding

In the competitive landscape of hospitality and specialized residential sectors, the choice of bedding significantly impacts guest satisfaction, operational costs, and brand perception. High-quality flannel sheets offer a compelling value proposition by combining unparalleled comfort and warmth with robust durability and aesthetic appeal. From meticulous raw material selection to advanced napping and finishing processes, every stage of manufacturing is geared towards producing a textile that excels in thermal insulation, softness, and longevity. The strategic integration of flannel into a diverse range of applications, from luxury hotels to healthcare facilities, demonstrates its versatility and proven ability to enhance user experience while providing a tangible return on investment through reduced energy consumption and extended product lifecycles. Partnering with a reputable manufacturer that offers customization, adheres to stringent quality standards, and provides comprehensive support ensures a seamless procurement experience and a lasting positive impact on your business operations.

References

- International Organization for Standardization (ISO) – Official Website.

- OEKO-TEX Association – Official Website.

- ASTM International – Standards for Textiles.

- Textile Industry Market Analysis Reports, various reputable research firms (e.g., Grand View Research, Mordor Intelligence).

- American Association of Textile Chemists and Colorists (AATCC) – Test Methods.

-

Garment Washed Sheets Color Retention Prevents Fading After WashesNewsNov.14, 2025

-

Charcoal Bamboo Sheets Moisture-Wicking Property Enhances Sleep ComfortNewsNov.12, 2025

-

High Quality Satin Sheets Soft Touch Improves Hotel Guest ExperienceNewsNov.12, 2025

-

Poly Cotton Sheets Breathable Weave Reduces Skin Irritation For PatientsNewsNov.12, 2025

-

Microfiber Sheet Stain Resistant Feature Eases Hotel HousekeepingNewsNov.12, 2025

-

Polyester Cotton Bedding Durable Fabric Withstands Frequent Hotel WashesNewsNov.12, 2025

-

Microfiber Pillow Filling Even Distribution Prevents LumpingNewsNov.03, 2025