...

...

In conclusion, the elegance and practicality of 118 wide fabric make it a versatile and highly sought-after choice for both fashion and home decor enthusiasts. Its ability to create stunning drapes and curtains, soft furnishings, and sewing projects, coupled with its stylish options, make it a must-have for anyone looking to add a touch of sophistication and comfort to their living space.

Another advantage of using a light down duvet insert is that it is incredibly easy to care for. Most down duvets are machine washable, which means that you can keep them clean and fresh without any hassle Most down duvets are machine washable, which means that you can keep them clean and fresh without any hassle Most down duvets are machine washable, which means that you can keep them clean and fresh without any hassle Most down duvets are machine washable, which means that you can keep them clean and fresh without any hassle

Most down duvets are machine washable, which means that you can keep them clean and fresh without any hassle Most down duvets are machine washable, which means that you can keep them clean and fresh without any hassle light down duvet insert. Simply follow the manufacturer's instructions and tumble dry on low heat to ensure that your duvet insert stays in top condition.

light down duvet insert. Simply follow the manufacturer's instructions and tumble dry on low heat to ensure that your duvet insert stays in top condition.

Finally, consider using a mattress protector underneath your flat sheet. This will provide an additional layer of protection against spills and stains, keeping your mattress looking and feeling like new for years to come.

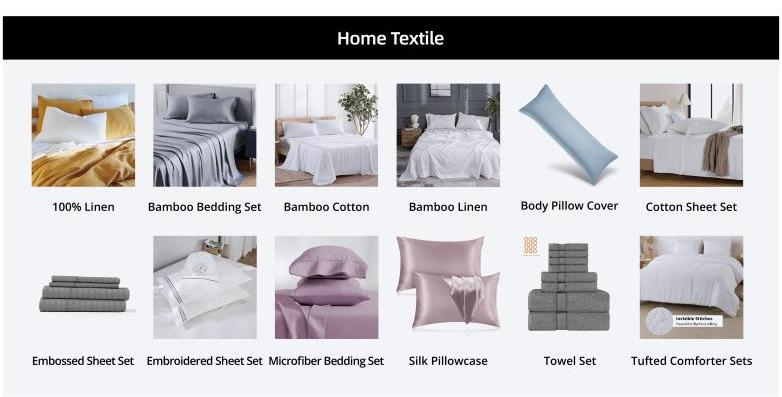

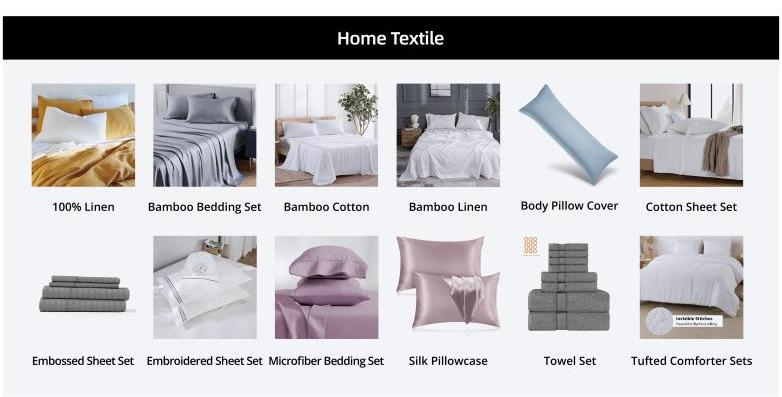

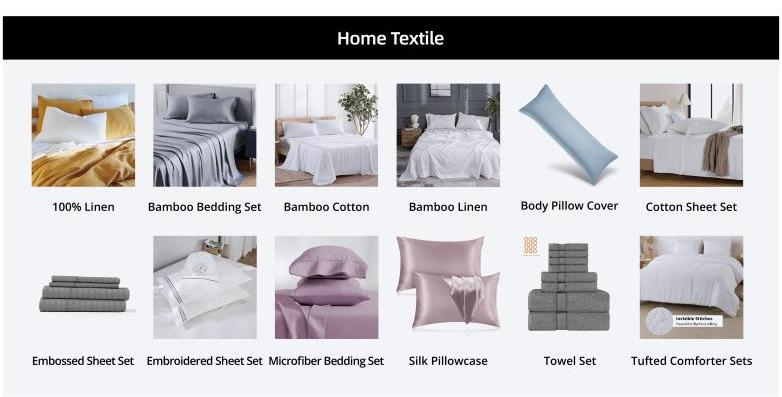

When it comes to the most absorbent bath towels, the fabric composition plays a crucial role in determining their effectiveness. The ideal towel should not only efficiently wick away moisture but also provide a soft and comfortable touch. Two materials that stand out for their exceptional absorbency are cotton and microfiber.

- The 6310 bearing is typically made from high-quality steel, which ensures its strength and durability. The steel used in this bearing is subjected to strict heat treatment processes to improve its hardness and wear resistance.

- Another significant advantage of this bearing is its low friction coefficient, which results in reduced energy loss and increased efficiency

- The Significance of Ball Bearing 625ZZ in Modern Engineering

- One of the key advantages of the 6211 2rs bearing is its ability to minimize friction and reduce heat generation during operation. This helps to extend the lifespan of the bearing and the equipment it is installed in. The two rubber seals on the bearing also act as a barrier against moisture and dirt, preventing premature wear and damage

6211 2rs bearing. - Conclusion

- | 6400 Series | 17 | 42 | 14 | 16 |

- The 6205 bearing is widely used in various industries due to its versatility and performance capabilities. Some common applications include

- 2. Outside diameter (D) The diameter of the outer race, measured in millimeters or inches.

- The 6218 ZZ bearing's durability and resistance to wear and tear make it an economic choice for businesses. Regular maintenance and lubrication can extend its lifespan significantly, reducing the need for frequent replacements and downtime. Moreover, its standardization allows for easy sourcing and interchangeability, simplifying inventory management.

- Introduction

- * Plastic Plastic bearings are lightweight, low friction, and corrosion-resistant

angular contact ball bearing size chart. They are suitable for low-load and low-speed applications.

angular contact ball bearing size chart. They are suitable for low-load and low-speed applications. - * Pumps and compressors These bearings are used in pumps and compressors to support the rotating shaft and ensure smooth operation

a deep groove ball bearing.

a deep groove ball bearing. The main difference between main bearings and thrust bearings lies in their specific functions within an engine or machinery:

- Firstly, the cost of raw materials is a primary determinant in the price of 22215 bearings. Steel, being the primary material, undergoes fluctuations in the global market, directly impacting the production cost. The quality of steel used also plays a role; high-grade materials often result in a higher price tag but guarantee better performance and durability.

- Understanding the dimensions of a 6403 bearing is vital for proper installation, maintenance, and performance optimization. It is crucial to ensure that the bearing fits snugly onto the shaft without any clearance, and that there is adequate space in the housing for it to function effectively. Misalignment or incorrect dimensions can lead to premature failure or reduced efficiency.

- Features of the 48548 Bearing

- One of the most common applications of tapered roller bearings is in the automotive industry, particularly in the wheel hub assemblies of cars, trucks, and other vehicles. They effectively manage the radial and axial forces generated during acceleration, braking, and cornering, ensuring smooth and safe operation. In addition, they are used in differentials and transmission systems, where they handle high torque and shock loads.

- When selecting spherical plain bearings, it is essential to consider the following factors

- 2. Outer Diameter 47 mm

- Automotive Vehicles: Bearings are essential components in automotive applications, including engines, transmissions, wheels, and suspension systems. They are used in wheel hubs, crankshafts, camshafts, and other rotating parts to reduce friction and support rotational motion.

- In conclusion, deep groove ball bearings, with their robust design and versatility, have become indispensable in modern engineering. Their continued evolution, driven by advancements in materials science and manufacturing techniques, promises even higher performance and durability in the future. Despite their simplicity, these bearings play a pivotal role in the efficient functioning of numerous devices and systems, making them a cornerstone of mechanical engineering.

- Investing in the 6004z bearing is an investment in the future of any industrial setup. It offers a competitive edge by ensuring that operations run smoothly without breaking the bank. As companies strive for excellence in their field, the 6004z bearing proves to be a reliable partner, providing stability in motion and peace of mind in budgeting.

- When selecting a taper roller bearing, it is important to consider factors such as load capacity, speed rating, and temperature range

taper roller bearing catalogue. By choosing the right bearing for the application, you can ensure optimal performance and long service life. - In the realm of manufacturing, efficiency is paramount. It dictates how quickly products are produced, how much they cost to make, and ultimately, how successful a company can be. One critical component in this efficiency equation is the bearing manufacturing machine. These advanced tools have revolutionized the production process, enabling manufacturers to produce bearings with unprecedented speed, accuracy, and quality.

- Outer Diameter (OD)

- The AN 2002 series ball bearing is made from high-quality materials such as chrome steel or stainless steel, which ensures durability and reliability. These bearings are also available in different sizes and configurations to suit the specific requirements of different applications

an 02 series single row deep groove ball bearing.

- Despite their advantages, double-row deep groove ball bearings may not be suitable for all applications. Their larger size and weight make them less ideal for lightweight or compact designs, and they may not be necessary for applications with lower load requirements. In such cases, single-row deep groove ball bearings or other types of bearings may be a more appropriate choice.

- In addition to these dimensions, the size chart may also include details about the roller diameter and length, which contribute to the bearing's efficiency and load distribution. The number of rollers in the bearing, the roller arrangement, and the cage type are also specified, as they affect the bearing's performance and service life.

- Overall, cylindrical roller bearings are a versatile and reliable solution for a wide range of industrial applications. Their excellent load capacity, high speed performance, and long service life make them a popular choice among engineers and manufacturers. With proper care and maintenance, these bearings can provide years of reliable service in even the most demanding environments.

- * Machine tools Used in spindle bearings, guideways, and feed screws to ensure precise movement and high speed operation.

- On the other hand, ball bearings utilize spherical balls to maintain separation between moving parts. They are known for their ability to handle both radial and axial loads, making them versatile in various applications. Ball bearings typically have lower friction and can operate at higher speeds compared to cylindrical roller bearings. Their compact size also makes them suitable for smaller, more compact machinery such as dental drills, computer hard drives, and automotive wheel hubs.

- The 6002RS bearing is a popular choice in the world of mechanical engineering due to its exceptional performance and reliability. These bearings are designed to withstand high speeds, heavy loads, and harsh operating conditions, making them an ideal choice for a wide range of applications.

- 2. Reduced Maintenance Costs The long life and low wear of the 6301 bearing result in lower maintenance costs and downtime.

- The 638 ZZ Bearing A Comprehensive Guide

- The Intricacies of Deep Groove Ball Bearings in SolidWorks

- 3

- 1. Cleaning Regularly clean the bearings to remove dirt and debris that can cause wear and tear.

- Bearings are an integral component in mechanical systems, facilitating the smooth rotation of parts and reducing friction. Among various types of bearings, the 627zz model is a specific kind, typically used in applications requiring high-speed performance and durability. The dimensions of these bearings are crucial to their function and compatibility with different machinery setups.

- Step 7 Testing

- Conclusion

- Designing magnetic bearings involves several critical factors, including the choice of materials, the size and shape of the magnets, and the control system. The material selection is crucial as it affects the strength and efficiency of the magnetic field. Rare-earth magnets, such as neodymium iron,are commonly used due to their high magnetic energy density Rare-earth magnets, such as neodymium iron,are commonly used due to their high magnetic energy density

Rare-earth magnets, such as neodymium iron,are commonly used due to their high magnetic energy density Rare-earth magnets, such as neodymium iron,are commonly used due to their high magnetic energy density

Rare-earth magnets, such as neodymium iron,are commonly used due to their high magnetic energy density Rare-earth magnets, such as neodymium iron,are commonly used due to their high magnetic energy density magnetic bearings theory design and application to rotating machinery. The size and shape of the magnets must be carefully chosen to ensure optimal performance and stability. Additionally, the control system must be designed to accurately sense and control the rotor's position, ensuring stable operation.

magnetic bearings theory design and application to rotating machinery. The size and shape of the magnets must be carefully chosen to ensure optimal performance and stability. Additionally, the control system must be designed to accurately sense and control the rotor's position, ensuring stable operation. - The 51124 thrust ball bearing, with its precise engineering and robust construction, not only improves system performance but also extends the lifespan of. Regular maintenance and proper lubrication can ensure optimal performance and prevent premature failure, thereby reducing downtime and maintenance costs.

- Automotive Applications: Roller bearings are widely used in automotive components such as wheel hubs, transmissions, differentials, and steering assemblies. They are valued for their ability to handle both radial and axial loads, making them suitable for various vehicle applications.

- Benefits of Using the 23268 Bearing

- Construction and mining equipment also heavily rely on these bearings

- Machinery and Equipment: Spherical roller bearings are employed in various industrial machinery and equipment, including conveyors, crushers, mixers, and vibrating screens. Their ability to accommodate heavy radial and axial loads, as well as misalignment, makes them suitable for demanding applications in industrial settings.

- An In-depth Look at Thrust Bearings by Size

- Double row deep groove ball bearings are a reliable and versatile solution for a wide range of applications. By understanding their design, specifications, applications, and maintenance requirements, users can select the appropriate bearing for their specific needs and ensure optimal performance and longevity.

Its moisture-wicking properties keep the pillow fresh and dry, preventing the growth of bacteria and fungi Its moisture-wicking properties keep the pillow fresh and dry, preventing the growth of bacteria and fungi

Its moisture-wicking properties keep the pillow fresh and dry, preventing the growth of bacteria and fungi Its moisture-wicking properties keep the pillow fresh and dry, preventing the growth of bacteria and fungi Most down duvets are machine washable, which means that you can keep them clean and fresh without any hassle Most down duvets are machine washable, which means that you can keep them clean and fresh without any hassle

Most down duvets are machine washable, which means that you can keep them clean and fresh without any hassle Most down duvets are machine washable, which means that you can keep them clean and fresh without any hassle Egyptian and Pima cotton, known for their extra-long staple fibers, provide exceptional softness and durability Egyptian and Pima cotton, known for their extra-long staple fibers, provide exceptional softness and durability

Egyptian and Pima cotton, known for their extra-long staple fibers, provide exceptional softness and durability Egyptian and Pima cotton, known for their extra-long staple fibers, provide exceptional softness and durability

Rare-earth magnets, such as neodymium iron,are commonly used due to their high magnetic energy density Rare-earth magnets, such as neodymium iron,are commonly used due to their high magnetic energy density

Rare-earth magnets, such as neodymium iron,are commonly used due to their high magnetic energy density Rare-earth magnets, such as neodymium iron,are commonly used due to their high magnetic energy density