...

2025-08-15 06:58

590

...

2025-08-15 06:47

2073

...

2025-08-15 06:45

976

...

2025-08-15 06:14

962

...

2025-08-15 06:10

2920

When choosing bed linen, thread count often comes into play. Generally, the higher the thread count, the softer and more durable the fabric. However, it's not just about the number; the quality of the yarn and the weave also play crucial roles. Egyptian cotton, for example, is renowned for its long fibers, resulting in a smoother and more durable bed linen.

...

2025-08-15 06:03

1902

Firstly, raw materials play a significant role. Towels are primarily made from cotton, which is a commodity subject to fluctuations in global markets. The quality of cotton, whether organic or conventional, Egyptian or Turkish, directly impacts the initial manufacturing cost. Add to this the energy and water consumed during the spinning, weaving, and dyeing processes, all of which contribute to the environmental footprint and the final price tag.

...

2025-08-15 06:00

1940

Organic Wool Duvet Insert

...

2025-08-15 05:42

1966

Embracing Luxury and Comfort with Extra Large Cotton Towels

...

2025-08-15 04:38

116

Every component in a control box is selected for its ability to perform under specific conditions – from extreme temperatures to the threat of corrosion. It’s this thoughtful assembly that makes the control box not just a container, but a finely tuned instrument crucial for the smooth operation of electrical systems.

heat tape electric.

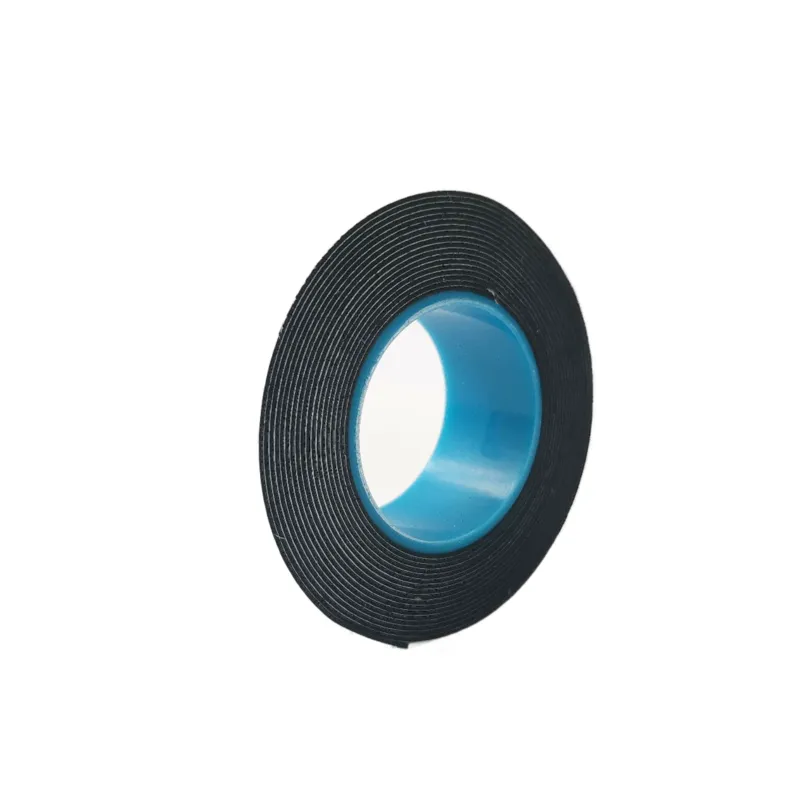

TAPES & SEALANTS

Construction:In the construction industry, butyl sealant tape is widely used to seal joints, seams, and gaps in various building materials, such as roofing membranes, window frames, and metal panels.

TAPE IS YOUR TRUSTED SOURCE FOR SINGLE COATED TAPES

Flex Tape Black is also designed to be removable, making it easy to reposition or replace the tape if needed. This makes it a great option for temporary fixes or projects where you may need to make adjustments down the line.