i choose you bedding

Durability is another hallmark of stonewashed linen sheets stonewashed linen sheets. Linen is known for its resilience, lasting several times longer than cotton. The stonewashing process further strengthens the fibers, reducing the likelihood of shrinkage or color fading. These sheets are designed to withstand the test of time, maintaining their charm and quality even after numerous washes.

stonewashed linen sheets. Linen is known for its resilience, lasting several times longer than cotton. The stonewashing process further strengthens the fibers, reducing the likelihood of shrinkage or color fading. These sheets are designed to withstand the test of time, maintaining their charm and quality even after numerous washes.

...

2025-08-14 05:11

1058

...

2025-08-14 05:06

1511

Another key feature of the T300 is its temperature regulating properties

...

2025-08-14 04:48

1772

A duvet insert protector, often overlooked, is an essential component in maintaining the longevity and hygiene of your bedding. It serves as a shield for your duvet insert, safeguarding it from stains, allergens, and general wear and tear, thereby enhancing its overall performance and durability.

...

2025-08-14 04:30

377

Bedding exporter specializes in sourcing, manufacturing, and distributing a wide range of bedding products, including bed linens, comforters, pillows, and mattress protectors. These exporters work closely with manufacturers to ensure that the products meet the highest quality standards and comply with all relevant regulations.

...

2025-08-14 04:23

1249

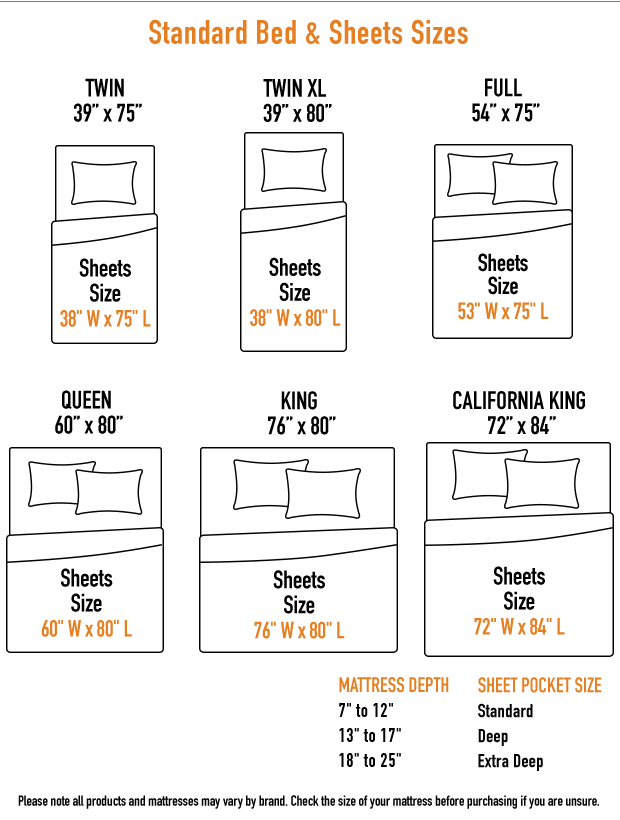

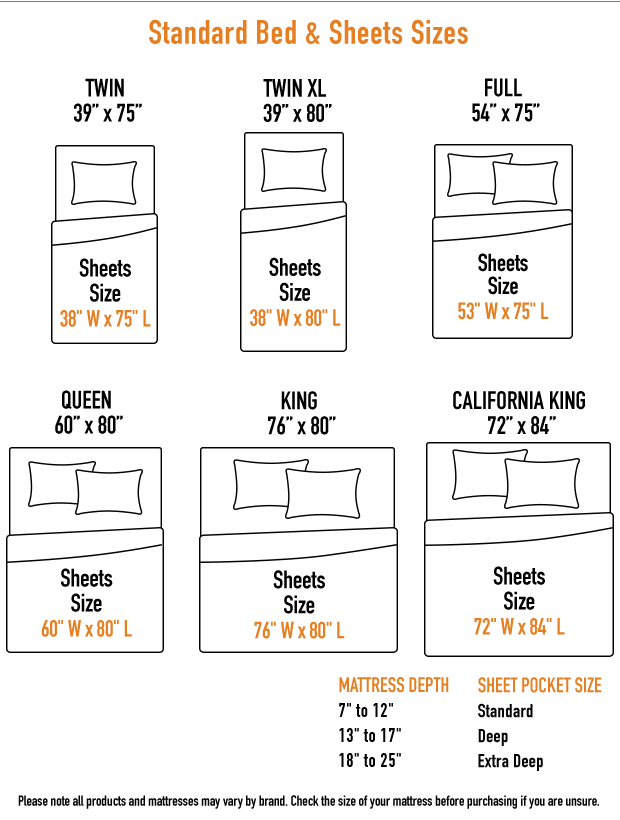

2. Size Measure your bed before purchasing a duvet cover set to ensure a perfect fit. Standard sizes include twin, full, queen, and king. Consider your personal preferences and the size of your bed when choosing the right size.

...

2025-08-14 04:00

1076

Egyptian Cotton Bedding

...

2025-08-14 03:25

712

Additionally, microfiber sheets are lightweight and thin, which can also help prevent overheating. Unlike some other types of sheets, microfiber sheets do not trap heat, allowing air to circulate and keep you cool.

...

2025-08-14 03:18

2441

Another key feature of the T300 is its temperature regulating properties

A duvet insert protector, often overlooked, is an essential component in maintaining the longevity and hygiene of your bedding. It serves as a shield for your duvet insert, safeguarding it from stains, allergens, and general wear and tear, thereby enhancing its overall performance and durability.

Bedding exporter specializes in sourcing, manufacturing, and distributing a wide range of bedding products, including bed linens, comforters, pillows, and mattress protectors. These exporters work closely with manufacturers to ensure that the products meet the highest quality standards and comply with all relevant regulations.

2. Size Measure your bed before purchasing a duvet cover set to ensure a perfect fit. Standard sizes include twin, full, queen, and king. Consider your personal preferences and the size of your bed when choosing the right size.

Egyptian Cotton Bedding

Additionally, microfiber sheets are lightweight and thin, which can also help prevent overheating. Unlike some other types of sheets, microfiber sheets do not trap heat, allowing air to circulate and keep you cool.

4. Shaft Sleeves

In addition to its shape and size, the material used for the volute's construction is also important. Typically, materials such as cast iron, stainless steel, or thermoplastics are employed, chosen based on factors like fluid characteristics, temperature, and pressure. For example, corrosive fluids may necessitate the use of more durable materials to prevent degradation and ensure longevity.

- Head: Calculate the total head required (static head plus friction losses).

Tailings management is a critical aspect of mining operations, requiring reliable equipment to handle the byproducts of extraction processes. OEM horizontal slurry pumps are designed to manage the unique challenges associated with tailings, such as the need for pumps that can withstand the abrasive nature of the slurry and the constant demand for high efficiency. These pumps are essential in transporting tailings to designated storage areas, where they can be safely contained and processed. The use of horizontal slurry pumps in tailings management helps minimize environmental impact, as these pumps are capable of handling large volumes of material with minimal leakage or spillage. Additionally, AH slurry pump parts ensure that the pumps maintain their performance over time, even under the harsh conditions often found in tailings processing.

The centrifugal slurry pump design plays a significant role in the effective transportation of slurry in mining operations. The design ensures that the pump can handle high-density materials without compromising performance. This is particularly important in mining, where the slurry often contains heavy and abrasive particles that can wear down pump components. The robust construction and optimized design of horizontal slurry pumps allow them to move large volumes of slurry over long distances, ensuring that materials are efficiently transported from extraction sites to processing facilities. By selecting the appropriate centrifugal pump for slurry, mining operations can maintain consistent material flow, reduce downtime, and enhance overall productivity.

Function: The backplate provides structural support and helps in mounting the pump.

1. Understand Your Application Requirements

Understanding the Role of Propeller Pumps in Various Applications

6. Bearing Assemblies

Conclusion

5. Evaluate Additional Features

- Type of Slurry: Determine if the slurry is abrasive, corrosive, or contains large particles.

- Locate your required flow rate and head on the chart to find potential pump models.

The Role of the Volute in Centrifugal Pumps

4. Check Pump Performance Curves

In various industrial sectors, the efficient handling and transportation of slurry— a mixture of solids and liquids— is critical. Whether in mining, construction, or wastewater treatment, the need for reliable machinery to manage these challenging substances has led to the increased utilization of slurry pumps. Among these, wholesale slurry pumps have emerged as a vital resource, offering a practical solution for businesses looking to optimize their operations.

Understanding the Role of Propeller Pumps in Various Applications

- Locate your required flow rate and head on the chart to find potential pump models.

Efficient pump operation is critical for many industrial processes, and the maintenance of pump wear parts plays a vital role in ensuring reliability and reducing downtime. Properly managing the replacement cycle of components is essential for maintaining optimal pump performance. This article explores how to determine the best replacement cycle for these critical components, focusing on wear assessment, runtime tracking, and performance monitoring.

In quarrying, the separation of sand and gravel is a vital process that requires reliable equipment. Horizontal slurry pumps are particularly well-suited for this task, as they can efficiently handle the slurry mixture of sand, gravel, and water. The centrifugal slurry pump design ensures that these materials are separated and transported to their respective storage or processing areas with minimal energy consumption. By utilizing OEM horizontal slurry pumps, quarry operations can streamline their processes, reduce operational costs, and improve the quality of the final product. The durability and efficiency of these pumps make them a cost-effective solution for handling the abrasive and coarse materials commonly found in quarries.

In line vertical pumps are specifically designed to save space while delivering efficient performance. These pumps are installed directly in the pipeline, with the motor positioned vertically, reducing the overall footprint of the pump system. This design is particularly beneficial in applications where space is limited, but high performance is still required. In line vertical pumps are commonly used in HVAC systems, water treatment plants, and other industries where compact, efficient pumping solutions are needed. The vertical orientation of these pumps also allows for easier alignment and installation, which can reduce the time and cost associated with setting up a pump system.

Wear Factors: Casings can wear down due to the abrasive slurry and need regular inspection and maintenance.

7. Expeller and Expeller Rings

Efficiency Testing for AH Slurry Pump Parts

4. Shaft Sleeves

Sewage pump impellers play a crucial role in the effective management of wastewater systems

. These specialized components are designed to transport sewage and wastewater from lower to higher elevations, ensuring that sewage is directed away from residential and commercial properties to treatment facilities. Understanding the functionality and types of sewage pump impellers can help in selecting the right pump for specific applications.Wear Factors: Seals can degrade over time due to contact with abrasive slurry and need regular replacement.

The performance of horizontal slurry pumps in mining and quarrying is heavily influenced by the quality of their components. AH slurry pump parts are specifically designed to withstand the wear and tear associated with abrasive slurries. Regular maintenance and timely replacement of these parts are essential for ensuring that the pumps continue to operate at peak efficiency. By investing in high-quality AH slurry pump parts, operators can extend the lifespan of their equipment, reduce the frequency of repairs, and minimize downtime. This proactive approach to maintenance not only enhances productivity but also contributes to a safer and more reliable working environment in mining and quarry operations.

- Ensure the pump has adequate NPSH available to avoid cavitation.

a. Slurry Characteristics:

Conclusion

Cost Reduction through Efficient Horizontal Slurry Pumps Operation

One of the primary advantages of purchasing wholesale slurry pumps is cost efficiency. When companies buy in bulk, they can take advantage of reduced prices, resulting in significant savings. This is especially beneficial for large-scale projects where multiple pumps are required. In addition, wholesale suppliers typically offer a wide range of models and specifications, allowing businesses to choose the most appropriate pump according to their unique needs. This capability ensures that operations can run smoothly and efficiently without significant downtime caused by equipment failure.

Materials: High-chrome iron, ductile iron, and stainless steel are commonly used materials.