3. Silk Silk is a luxurious bedding material that is known for its smooth texture and ability to regulate temperature. It is naturally hypoallergenic and resistant to dust mites, making it an excellent choice for allergy sufferers. Silk bedding is also lightweight and breathable, providing a comfortable sleeping environment year-round Silk bedding is also lightweight and breathable, providing a comfortable sleeping environment year-round

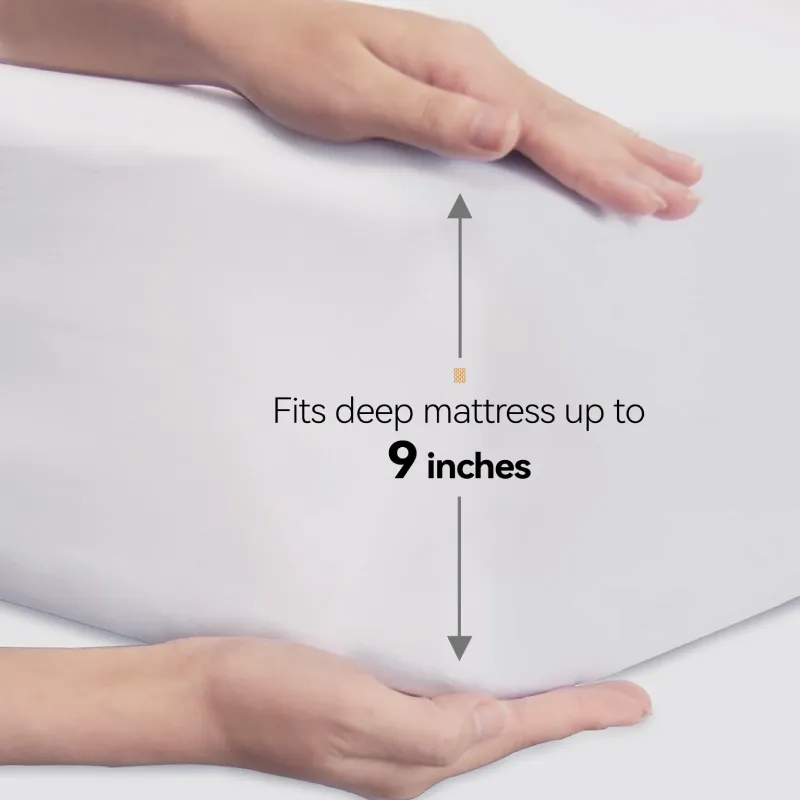

Hotel standard bed sheets are also designed with a precise fit in mind. They are tailored to snugly cover the mattress, preventing any unwanted shifting during the night. This attention to detail ensures that guests wake up to a well-made bed each morning, contributing to the overall tidiness and ambiance of the room This attention to detail ensures that guests wake up to a well-made bed each morning, contributing to the overall tidiness and ambiance of the room

- In the pharmaceutical industry, HPMC is often used as a coating agent for tablets and capsules. It helps to protect the active ingredients in medication from being degraded by stomach acid, and also ensures that the medication is released gradually in the body, leading to better absorption and effectiveness. HPMC is also used in ophthalmic solutions, where it helps to increase the viscosity of the solution, allowing for better contact with the eye.

Several factors influence the properties of HPMC, including the degree of substitution, the molecular weight of cellulose used, and the reaction conditions during synthesis.

HPMC & Heavy Metals

4. Grout HPMC is often included in grout formulations to improve consistency, reduce shrinkage, and enhance adhesion, resulting in long-lasting and effective joints between tiles.

1. Enhanced Adhesion One of the primary benefits of using China redispersible powder is the enhancement of adhesion characteristics in mortar and adhesive formulations. This feature ensures that tiles, plasters, and other materials stay securely in place.

Several factors influence the viscosity of HPMC, including concentration, temperature, and the degree of substitution. Increasing the concentration of HPMC will typically lead to higher viscosity. Temperature also plays a critical role; viscosity may decrease with rising temperatures. The degree of substitution, or the amount of methoxy and hydroxypropyl groups present, also affects viscosity—higher substitutions usually result in increased solubility and varying viscosity profiles.

Personal Care Products

Manufacturers invest in research and development to innovate and enhance the properties of HEC. This continuous improvement not only elevates the quality of the product but also expands its range of applications.

5. Biocompatibility Being non-toxic and biodegradable, HPMC is widely used in pharmaceutical formulations, especially in drug delivery systems and as a binder in tablets.

Conclusion

HPMC is derived from cellulose, which is a naturally occurring polysaccharide found in the plant cell walls. The process of creating HPMC begins with the extraction of cellulose from wood pulp or cotton linters. These natural sources consist primarily of long chains of glucose units linked together, forming the cellulose structure. This raw cellulose powder serves as the starting material for synthesizing HPMC.

In contrast, HPMC's versatility allows for broader applications. It is widely used as a thickening agent in cosmetics and personal care products, providing a smooth, creamy texture. Additionally, HPMC plays a crucial role in the food industry, where it acts as a stabilizer and emulsifier in products like sauces and dressings. Its ability to form gels also makes it suitable for gluten-free baking products as a substitute for wheat gluten.

HPMC Limited also invests in its workforce, recognizing that employees are a vital component of its success. The company fosters a positive working environment, encouraging continuous learning and professional development. By empowering its employees and recognizing their contributions, HPMC creates a motivated team that is dedicated to achieving shared goals.

Several factors affect the pricing of RDP powder

Has a lower viscosity than HPMC, making it more suitable for certain applications where a thinner consistency is desired

Role in Construction Materials

Applications of HPMC with Consideration of Density

methyl hydroxyethyl cellulose mhec. Its ability to improve viscosity, mouthfeel, and shelf life of food products makes it a popular ingredient among food manufacturers. MHEC is also used in low-fat and reduced-sugar products to enhance their texture and sensory attributes.

Some of the well-known HPMC manufacturers in China include

Applications in Pharmaceuticals

Styrene-acrylate copolymers are another prevalent category of RDPs. These powders offer high water resistance and good film-forming capabilities, making them suitable for applications such as floor adhesives, wall coatings, and waterproofing membranes. The incorporation of styrene into the polymer structure enhances the gloss and durability of the final products. However, while styrene-acrylate systems provide substantial water repellency, they may not offer the same level of flexibility as VAE copolymers.

HPMC

1. Binders In tablet formulations, HPMC serves as a binder due to its excellent adhesive properties. It helps maintain the tablet's structural integrity and ensures uniform distribution of the API.

Understanding Hydroxyethyl Cellulose

What is HPMC Made From?

Understanding HPMC

3. Dispersibility

Hydroxypropyl Methylcellulose (HPMC) is a versatile and widely used polymer in a variety of industries, ranging from pharmaceuticals and construction to food and cosmetics. As a cellulose ether, HPMC offers unique properties such as thermal stability, solubility in water, and a smooth texture, making it a valuable ingredient in many formulations. The significance of HPMC manufacturers cannot be understated, as they play a crucial role in ensuring the consistency and quality of this essential compound.

Moreover, RDPs serve to enhance water resistance and reduce permeability. This is essential in coatings and waterproofing applications, where moisture ingress can lead to significant damage and deterioration. By incorporating RDPs, manufacturers can create products that maintain their performance even under challenging weather conditions, ensuring long-term effectiveness.

redispersible polymer powder wikipedia

Hydroxypropyl MethylCellulose is a non-ionic cellulose ether, in the appearance of white powder, odorless and tasteless. It is soluble in water, most polar organic solvents, and the appropriate proportion of ethanol/water, propanol /water and dichloroethane, but insoluble in diethyl ether, acetone, and anhydrous alcohol. In cold water, it will swell into a clear or slightly turbid colloidal solution.

2. Increased Workability Superplasticizers, a type of cement additive, increase the workability of the cement mix without the need for excess water. By reducing the water-cement ratio, these additives help achieve a more cohesive and workable mixture. This is especially advantageous in complex architectural designs where precise application and formwork are required.

cement adhesive additive

The cosmetic industry has also embraced HPMC for its thickening and film-forming abilities. It is commonly found in lotions, creams, shampoos, and other personal care products, contributing to a pleasant texture and increased stability. HPMC is non-irritating and suitable for sensitive skin, making it an ideal ingredient in a variety of formulations. Its capacity to enhance moisture retention ensures that cosmetic products not only apply smoothly but also provide lasting hydration benefits.

Where to Buy Cellulose Hydroxyethyl Cellulose A Comprehensive Guide

Applications in the Food Industry

Silk bedding is also lightweight and breathable, providing a comfortable sleeping environment year-round Silk bedding is also lightweight and breathable, providing a comfortable sleeping environment year-round

Silk bedding is also lightweight and breathable, providing a comfortable sleeping environment year-round Silk bedding is also lightweight and breathable, providing a comfortable sleeping environment year-round This attention to detail ensures that guests wake up to a well-made bed each morning, contributing to the overall tidiness and ambiance of the room This attention to detail ensures that guests wake up to a well-made bed each morning, contributing to the overall tidiness and ambiance of the room

This attention to detail ensures that guests wake up to a well-made bed each morning, contributing to the overall tidiness and ambiance of the room This attention to detail ensures that guests wake up to a well-made bed each morning, contributing to the overall tidiness and ambiance of the room