In controlled drug delivery systems, HPMC's ability to form gels ensures a sustained release of active ingredients, improving patient compliance and efficacy In controlled drug delivery systems, HPMC's ability to form gels ensures a sustained release of active ingredients, improving patient compliance and efficacy

In controlled drug delivery systems, HPMC's ability to form gels ensures a sustained release of active ingredients, improving patient compliance and efficacy In controlled drug delivery systems, HPMC's ability to form gels ensures a sustained release of active ingredients, improving patient compliance and efficacy hydroxypropyl methylcellulose hpmc powder.

hydroxypropyl methylcellulose hpmc powder. hpmc hs code. Companies dealing with HPMC need to be well-versed in these codes to ensure accurate declarations and avoid potential legal issues.

hpmc hs code. Companies dealing with HPMC need to be well-versed in these codes to ensure accurate declarations and avoid potential legal issues. Its emulsifying and stabilizing properties make it a popular choice for hair and skincare products Its emulsifying and stabilizing properties make it a popular choice for hair and skincare products

Its emulsifying and stabilizing properties make it a popular choice for hair and skincare products Its emulsifying and stabilizing properties make it a popular choice for hair and skincare products methyl hydroxyethyl cellulose mhec. It improves the texture and consistency of lotions, shampoos, and conditioners, providing a smooth, silky feel. Furthermore, MHEC acts as a suspending agent, preventing the separation of ingredients in formulations.

methyl hydroxyethyl cellulose mhec. It improves the texture and consistency of lotions, shampoos, and conditioners, providing a smooth, silky feel. Furthermore, MHEC acts as a suspending agent, preventing the separation of ingredients in formulations.WARNING/CAUTION: Even though it may be rare, some people may have very bad and sometimes deadly side effects when taking a drug. Tell your doctor or get medical help right away if you have any of the following signs or symptoms that may be related to a very bad side effect:

The edges are finished with a sophisticated hemstitch detail, adding an elegant touch to your bathroom decor The edges are finished with a sophisticated hemstitch detail, adding an elegant touch to your bathroom decor

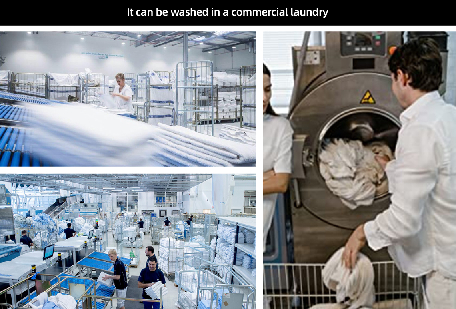

The edges are finished with a sophisticated hemstitch detail, adding an elegant touch to your bathroom decor The edges are finished with a sophisticated hemstitch detail, adding an elegant touch to your bathroom decor It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details

It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details

RDP can be used as a feedstock material in 3D printing, allowing for the creation of complex and intricate designs that would be difficult or impossible to produce using traditional manufacturing methods RDP can be used as a feedstock material in 3D printing, allowing for the creation of complex and intricate designs that would be difficult or impossible to produce using traditional manufacturing methods

RDP can be used as a feedstock material in 3D printing, allowing for the creation of complex and intricate designs that would be difficult or impossible to produce using traditional manufacturing methods RDP can be used as a feedstock material in 3D printing, allowing for the creation of complex and intricate designs that would be difficult or impossible to produce using traditional manufacturing methods