...

2025-08-17 03:33

2248

...

2025-08-17 03:22

1955

...

2025-08-17 02:50

870

...

2025-08-17 02:43

642

...

2025-08-17 02:26

2357

...

2025-08-17 02:20

1340

...

2025-08-17 01:58

1962

...

2025-08-17 01:58

2688

...

2025-08-17 01:44

2650

...

2025-08-17 00:58

377

The primary function of hospital bed sheets is to ensure cleanliness. Given the high risk of infection in medical settings, these sheets are typically made from materials that can withstand frequent washing and sanitization without losing their integrity. Materials like cotton, polyester, or a blend of both are commonly used due to their ability to resist bacteria buildup, absorb moisture, and dry quickly. Furthermore, many hospital bed sheets feature a non-woven, waterproof backing to prevent fluid penetration, ensuring a hygienic barrier between the patient and the mattress.

The Significance of Hotel Type Towels in Enhancing Guest Experience

Color and pattern selection can greatly influence the ambiance of your bedroom

Another benefit of pure essentials sheets is their durability. Unlike cheaper sheets made from synthetic materials, these sheets are built to last. With proper care, they can withstand frequent washing and maintain their softness and color for years to come. This makes them a wise investment for those looking to upgrade their bedding and improve their sleep quality.

Will it serve its purpose?

- These new materials not only improve the performance of drill rods but also reduce the risk of accidents in underground mines. Traditional steel drill rods can become electrically charged when they come into contact with certain minerals, posing a serious safety hazard. However, composite materials are non-conductive, eliminating this risk.

- The origin of the 75mm drill bit can be traced back to the early 20th century when manual drilling was the primary method used to create holes in various materials. These early bits were made from high-speed steel (HSS) and had simple geometries, making them suitable for soft materials like wood and mild steel.

Lightweight

- Drill bits come in various sizes and types, each tailored to specific materials and drilling needs. The 34mm drill bit, with its large diameter, is typically made from high-quality materials such as high-speed steel (HSS) or carbide, ensuring durability and resistance to wear. These materials allow the bit to maintain sharpness and efficiency even when drilling through tough materials like metal, wood, or concrete.

- The process of designing a high-performance coupling sleeve begins with selecting the right material. This choice is crucial as it dictates the strength, durability, and weight of the final product. Materials such as steel, aluminum, or even composite materials can be used depending on the application. Each material has its unique properties that must be taken into account to ensure the sleeve can withstand the forces it will encounter.

- The Role of Handrails in Group Exercise Classes

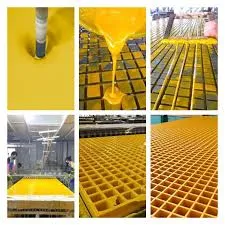

This makes them a preferred choice for companies committed to sustainable practices and reducing their environmental footprint This makes them a preferred choice for companies committed to sustainable practices and reducing their environmental footprint

This makes them a preferred choice for companies committed to sustainable practices and reducing their environmental footprint This makes them a preferred choice for companies committed to sustainable practices and reducing their environmental footprint This versatility, combined with their durability and low maintenance requirements, makes fiberglass ducts a popular choice for many industries This versatility, combined with their durability and low maintenance requirements, makes fiberglass ducts a popular choice for many industries

This versatility, combined with their durability and low maintenance requirements, makes fiberglass ducts a popular choice for many industries This versatility, combined with their durability and low maintenance requirements, makes fiberglass ducts a popular choice for many industries

Unlike wooden boats that require regular upkeep and refinishing, fiberglass vessels can be easily cleaned and maintained with simple soap and water Unlike wooden boats that require regular upkeep and refinishing, fiberglass vessels can be easily cleaned and maintained with simple soap and water

Unlike wooden boats that require regular upkeep and refinishing, fiberglass vessels can be easily cleaned and maintained with simple soap and water Unlike wooden boats that require regular upkeep and refinishing, fiberglass vessels can be easily cleaned and maintained with simple soap and water