non down duvet insert

Crafted with superior craftsmanship, these towels are made from premium cotton, which is renowned for its excellent absorbency and breathability. The cotton fibers are combed to remove impurities, resulting in a smoother texture that feels luxurious against your skin. Whether you're soaking up the sun at the beach or relaxing in the comfort of your own home, these towels will provide you with unparalleled comfort and warmth.

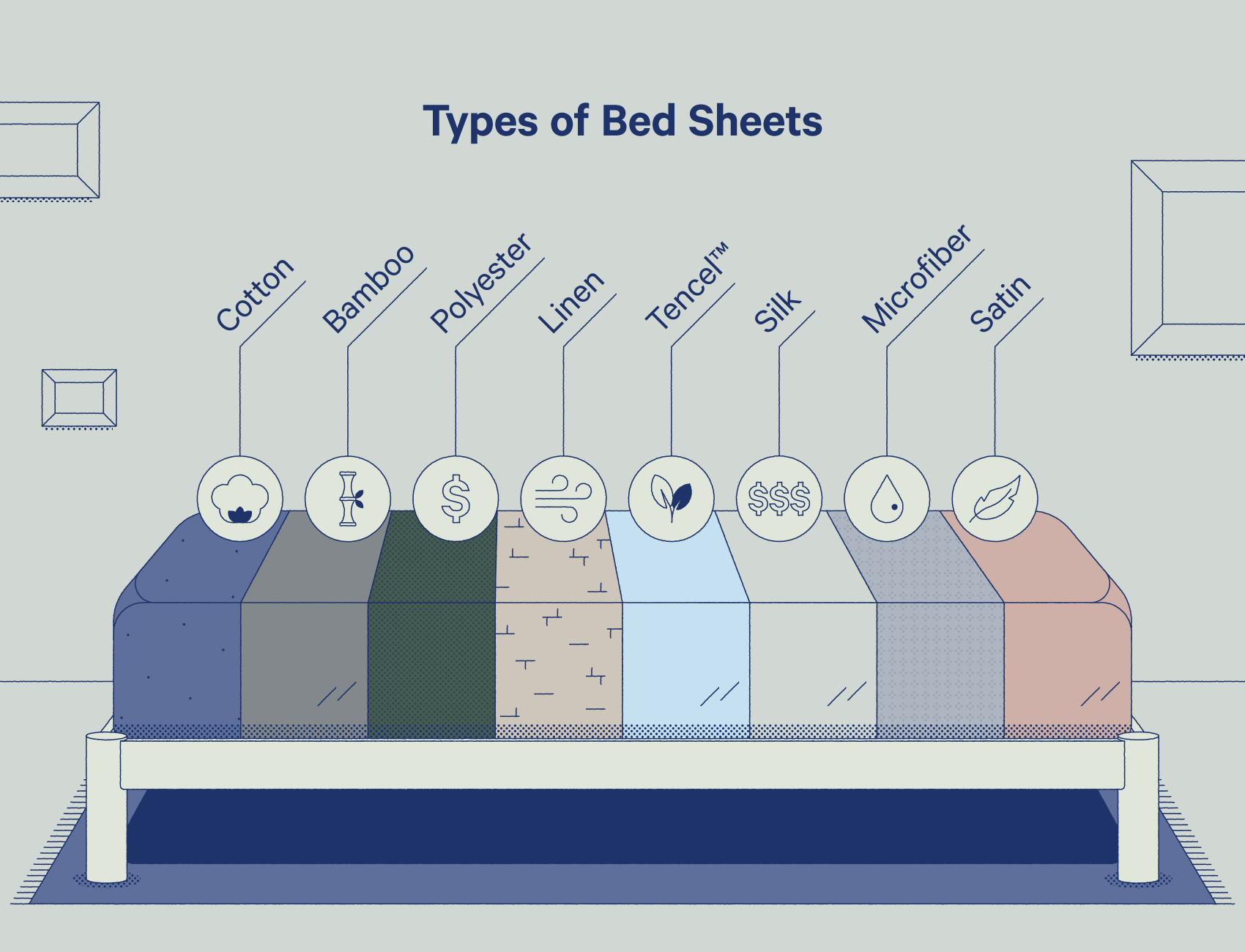

The function of hospital bed sheets goes beyond aesthetics. They contribute significantly to patient comfort. A well-fitted sheet can make all the difference in a patient's sleep quality, which in turn impacts their recovery process. The coolness and breathability of cotton help regulate body temperature, while the smooth texture provides a soothing surface against irritated or sensitive skin.

And when was the duvet invented?

By using a waterproof sheet, you can protect your mattress from these damaging elements, thereby reducing the need for frequent replacements By using a waterproof sheet, you can protect your mattress from these damaging elements, thereby reducing the need for frequent replacements

By using a waterproof sheet, you can protect your mattress from these damaging elements, thereby reducing the need for frequent replacements By using a waterproof sheet, you can protect your mattress from these damaging elements, thereby reducing the need for frequent replacements