The dimensions of a big duvet insert are designed to provide ample coverage, ensuring that even the most active of sleepers stay covered throughout the night. Unlike standard-sized duvets, these inserts boast a generous size that caters to the needs of larger beds or individuals who prefer the luxury of extra fabric draping around them.

* Skin Health Bamboo's natural antimicrobial properties can help reduce the risk of acne and other skin irritations, while its softness can help prevent bed sores and other pressure injuries 100 pure bamboo sheets.

100 pure bamboo sheets.

What Is Linen?

The Future of Plastic Bag Closer Machines

Looking ahead, the future of bulk bag sewing machines looks promising. As industries continue to grow and evolve, the demand for efficient and reliable packaging solutions will only increase. Companies investing in the latest technologies, such as IoT (Internet of Things) for predictive maintenance and smart manufacturing, will likely lead the way in optimizing production processes and enhancing overall efficiency.

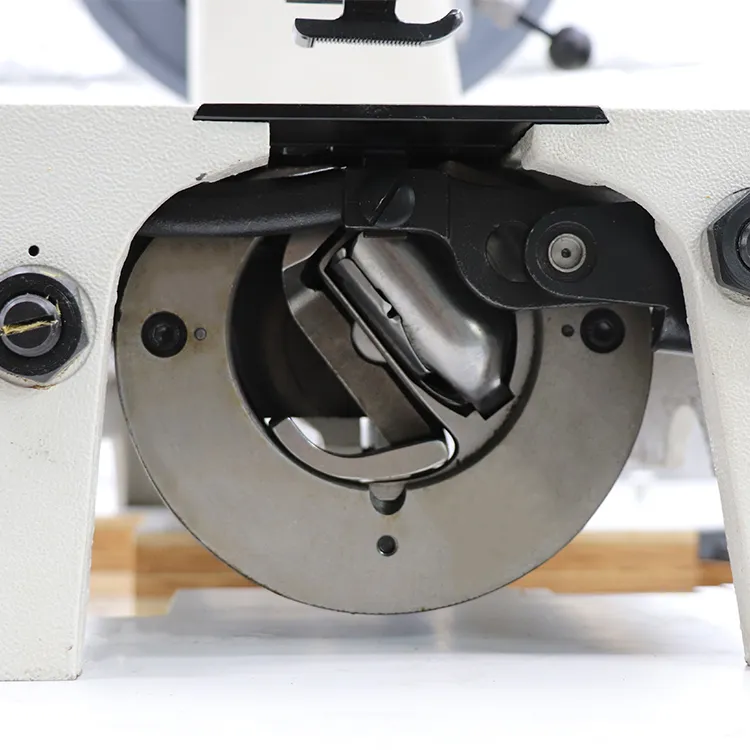

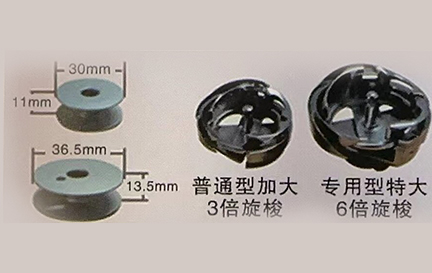

Features of a Sailmaker Sewing Machine

While the benefits of owning an overlocker are clear, they do require a learning curve. Unlike a traditional sewing machine, which primarily functions as a straight stitcher, overlockers can be more complex due to their threading mechanism and multiple feed options. However, with practice and patience, users often find that the time spent mastering this equipment pays off in the form of professionally finished garments.