washed linen bedding sale

...

...

...

...

...

...

...

...

...

...

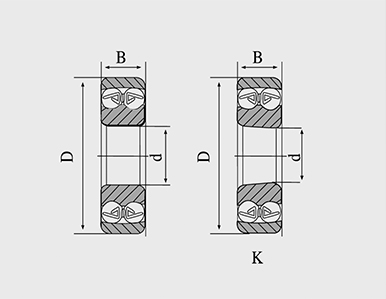

Proper installation is crucial for the longevity and performance of bearing ID 80 OD 140 taper roller bearings. Follow these steps for correct installation Material composition plays a crucial role in defining performance. Typically manufactured from high-carbon chromium steel, the 6211 bearing offers excellent hardness and wear resistance. For more demanding environments, variants may include ceramic or stainless steel components to enhance corrosion resistance and reduce friction. 2RS, however, paints a different picture. It could denote a model number in the world of hardware or electronics It could denote a model number in the world of hardware or electronics 6309 2rs A deep groove ball thrust bearing consists primarily of an outer ring, inner ring, balls, and a cage. The deep grooves in the rings provide a larger contact area for the balls, increasing the load-carrying capacity and allowing for higher speeds. The design also ensures a more uniform distribution of stress, leading to enhanced durability and longer service life. An In-depth Look at Tapered Bearing Cross Reference One of the key factors that make deep groove ball bearings stand out is their contact angle. The contact angle refers to the angle between the line connecting the contact points of the ball and the raceway and the horizontal plane. In deep groove ball bearings, the contact angle is typically between 15° and 25°. This unique design allows the bearings to accommodate both radial and axial loads simultaneously, making them highly versatile. Moreover, proper installation and maintenance of these bearings are equally important. Regular lubrication, cleaning, and timely replacement when signs of wear appear are necessary to maintain the bearing's efficiency and prevent premature failure. Moreover, regular maintenance and proper installation are crucial for maximizing the lifespan of the 6303 bearing. Regular cleaning, lubrication, and timely replacement when signs of wear are detected are essential practices to ensure optimal performance and prevent unexpected breakdowns. When interpreting a thrust needle roller bearing size chart, it's essential to consider the specific application's requirements, including the magnitude and direction of the load, operating speeds, and environmental factors. Compatibility with the housing, as well as any additional components like seals or washers, should also be assessed. The application of the 6308 z bearing extends across diverse fields such as industrial equipment, power transmission systems, and even heavy machinery used in mining operations 6308 z bearing Maintenance and Storage Introduction A taper roller bearing is a type of rolling-element bearing that is designed to handle both radial and axial loads. It consists of an inner ring, an outer ring, a cage, and tapered rollers. The inner and outer rings are tapered, with the inner ring being smaller in diameter than the outer ring. This design allows the bearing to handle radial loads by providing contact between the tapered rollers and the raceway on the inner and outer rings. Benefits of the 48548 Bearing 3. Enhanced Safety The reliability and stability of conical roller bearings contribute to enhanced safety in machinery operations. By reducing the risk of bearing failure, these bearings help prevent accidents and minimize downtime. Another important aspect of the 33217 bearing is its versatility 33217 bearing Conclusion These bearings are commonly used in industries like automotive, mining, construction, and power generation. Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity nj 307 bearing Maintenance and Troubleshooting 1. High Load Capacity The 51213 bearing is designed with a large contact area and a robust design, which enables it to withstand high loads and (torsional moments). The 6207 2RS is a deep groove ball bearing, a common type used in various industrial applications. The '6207' part of the code indicates the size of the bearing, referring to its inner diameter of 35mm and a standard width. The ' 2' signifies the series, which is a classification based on the bearing's dimensions and load-carrying capabilities. It is designed to handle both radial and axial loads, making it versatile for different applications. Another factor that may have influenced the price of bearing 6312 is the demand-supply dynamics in the market. The global demand for bearings has been steadily increasing due to the growth of various industries that rely on bearings for their operations. This increase in demand has put pressure on the supply chain, leading to a scarcity of bearings in the market. As a result, bearing manufacturers have been able to raise their prices to capitalize on the high demand. Understanding Tapered Roller Bearings ID 80, OD 140 * Pumps and compressors These bearings are used in pumps and compressors to support the rotating shaft and ensure smooth operation a deep groove ball bearing 3. Construction equipment Heavy-duty machinery used in construction, such as excavators and bulldozers, require bearings that can withstand extreme loads and rough operating conditions. Conical roller bearings meet these requirements and ensure long-lasting performance in these applications. Design and Construction Double row thrust ball bearings, an integral part of numerous mechanical and engineering systems, play a pivotal role in facilitating linear motion and withstanding heavy axial loads. These specialized bearings, with their unique design and functionality, have become indispensable in various industries due to their efficiency and durability. In conclusion, the bearing NU 208 is a robust and adaptable component in the world of mechanical engineering. Its design, characterized by a non-locating outer ring and cylindrical roller configuration, allows it to excel in environments where flexibility and load-bearing capacity are paramount. Whether it's a small motor or a large industrial machine, the NU 208 brings efficiency, reliability, and a touch of versatility to any system it serves. Leading spherical bearing manufacturers, such as SKF, Timken, NSK, and NTN, have established themselves as industry benchmarks due to their unwavering commitment to quality and technological advancement. Their manufacturing processes incorporate cutting-edge technology, precision engineering, and rigorous testing to ensure each product meets the highest standards. Introduction The brand of the bearing can significantly impact the price. Some reputable brands may have higher prices due to their reputation for quality and reliability. It's essential to consider the brand's track record and customer reviews to ensure you are getting a durable and long-lasting bearing. Thrust angular contact ball bearings are available in different designs, including single row, double row, and four-point contact 5. Versatility Cylindrical roller bearings can accommodate misalignment and are suitable for both radial and thrust loads, making them highly versatile. * Improved efficiency The high load capacity and stiffness of the bearing allow for increased operational efficiency, reducing downtime and maintenance costs In addition to its durability and load-bearing capacity, the 51312 thrust bearing is also known for its ease of installation and maintenance . With proper care and lubrication, this type of bearing can operate smoothly for extended periods without the need for frequent repairs or replacements51312 thrust bearing Deep groove ball bearings are characterized by their deep raceway grooves, which enable them to accommodate radial loads as well as moderate axial loads in both directions. These bearings are designed to operate at high speeds and are ideal for applications where the primary load is radial. Deep groove ball bearings have low friction and high rotational accuracy, making them popular in electric motors, gearboxes, and pumps. In conclusion, the 6301 diameter bearing is a superior product that offers unparalleled performance in terms of load-carrying capacity, durability, rotational stability, and ease of maintenance. Its combination of features and benefits makes it an excellent choice for a wide range of applications, making it a must-have for anyone in need of a reliable and efficient bearing solution. Overall, a tapered bearing puller is a valuable tool for anyone who works with tapered roller bearings. Its ability to safely and efficiently remove bearings makes it a must-have for mechanics, technicians, and DIY enthusiasts. By investing in a high-quality bearing puller, you can ensure that your bearings are removed properly, prolonging their lifespan and avoiding costly repairs. Whether you are working on a car, a tractor, or a piece of heavy machinery, a bearing puller is an essential tool that will make your job easier and more efficient. In addition to their high load-carrying capacity, four-row cylindrical roller bearings are also known for their long service life and low maintenance requirements * Reduced downtime The maintenance-free design of the bearing reduces downtime caused by maintenance or repairs Market dynamics, including supply and demand, competition, and global economic conditions, also significantly affect bearing prices. During periods of high demand or supply chain disruptions, prices may rise. Conversely, when the market is saturated or the economy slows down, prices might decrease to stimulate sales. 3. Lubricate the bearing according to the manufacturer's recommendations to ensure proper operation and reduce wear. This bearing finds its application in a broad spectrum of industries, from automotive to aerospace, from home appliances to precision instruments Over the years, the 6215 2RS bearing has been subjected to continuous refinement and improvement In conclusion, the price of cylindrical roller bearings is a reflection of a complex interplay between material quality, design intricacy, manufacturing processes, market forces, and additional services. As a buyer, it's essential to strike a balance between cost and performance, considering the specific needs of your application and the long-term benefits that a high-quality bearing can provide. Remember, while price is undoubtedly a significant factor, it's equally important to invest in a bearing that ensures reliability, efficiency, and a prolonged service life.

The duvet cover, while visually appealing and practical, relies on the insert to serve its intended purpose The duvet cover, while visually appealing and practical, relies on the insert to serve its intended purpose

The duvet cover, while visually appealing and practical, relies on the insert to serve its intended purpose The duvet cover, while visually appealing and practical, relies on the insert to serve its intended purpose do duvet covers need inserts. Without an insert, the cover would not provide the necessary insulation and comfort that a duvet is meant to offer. The cover acts as a casing, encasing the insert and keeping it in place, ensuring even distribution of warmth throughout the night.

do duvet covers need inserts. Without an insert, the cover would not provide the necessary insulation and comfort that a duvet is meant to offer. The cover acts as a casing, encasing the insert and keeping it in place, ensuring even distribution of warmth throughout the night. It could denote a model number in the world of hardware or electronics It could denote a model number in the world of hardware or electronics

It could denote a model number in the world of hardware or electronics It could denote a model number in the world of hardware or electronics 6309 2rs. In this context, it might refer to a specific version of a device, perhaps a cutting-edge microchip or a sophisticated sensor. Alternatively, it could be a coding standard or a unique identifier in a software development project.

6309 2rs. In this context, it might refer to a specific version of a device, perhaps a cutting-edge microchip or a sophisticated sensor. Alternatively, it could be a coding standard or a unique identifier in a software development project. 6308 z bearing. Its reliability makes it a preferred choice for applications where consistent performance is critical, like conveyor belt systems or electric motors.

6308 z bearing. Its reliability makes it a preferred choice for applications where consistent performance is critical, like conveyor belt systems or electric motors.

Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity

Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity Their ability to withstand intense operational stress, coupled with their resistance to fatigue and wear, ensures minimal downtime and increased productivity nj 307 bearing. The robust construction of NJ 307 bearings, with their high-quality steel and advanced lubrication systems, contributes to their extended service life.

nj 307 bearing. The robust construction of NJ 307 bearings, with their high-quality steel and advanced lubrication systems, contributes to their extended service life. a deep groove ball bearing.

a deep groove ball bearing.