The beauty of duvets lies in their versatility

Thin towels, also known as microfiber towels or compact towels, are designed with an ultra-thin structure that belies their remarkable absorbency. Made from a blend of polyester and nylon, they are incredibly lightweight and space-saving, making them ideal for travel, gym use, or even daily home use. Their thinness does not compromise their effectiveness; in fact, it enhances it. The tightly woven fibers create a surface area that can hold up to seven times its weight in water, drying quickly and efficiently.

The Importance of Hotel Standard Bed Sheets

In conclusion, satin cooling bed sheets are more than just a stylish addition to your bedroom. They offer a unique blend of comfort, cooling technology, and skincare benefits, making them a worthwhile investment for those seeking a superior sleep experience. Whether you're looking to combat hot summer nights or simply elevate your bedtime ritual, these sheets are a game-changer in the world of bedding. So, slip into the silky embrace of satin and discover a new level of restful, rejuvenating sleep.

All in all, the right combination of bedding types and accessories can transform your bedroom into a relaxing and visually appealing retreat. Whether you prefer a minimalist look or a more layered and decorative style, the key is to choose high-quality bedding that not only looks great but also promotes a restful sleep.

**The Erasable Advantage

Dismantling the Fence Safely

- The metal box, crafted from sturdy materials such as steel or aluminum, is a testament to durability. Its hardy exterior not only safeguards its contents from external damages but also withstands the wear and tear of daily use. The lid, seamlessly attached to the body, provides an airtight seal, protecting the items inside from dust, moisture, and potential tampering.

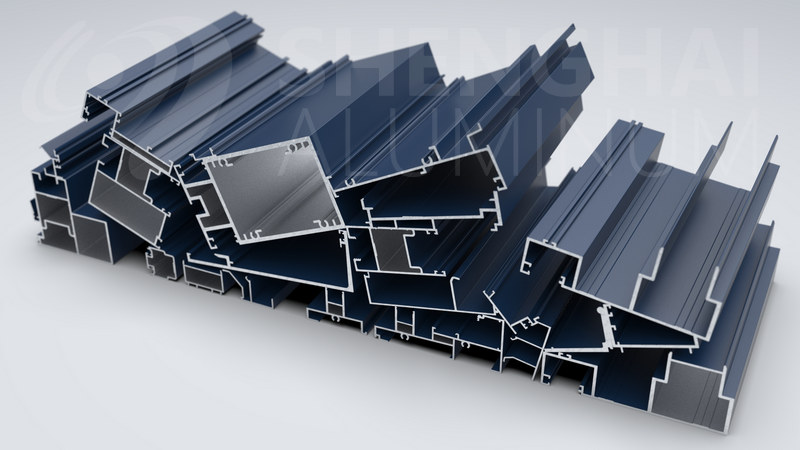

What are aluminum profiles?

- Remember, while DIY repairs can save you money, if you're not confident in your handyman skills, it's best to consult a professional. A skilled technician will have the expertise to handle the job efficiently and prevent potential damage.

- It is made of light aluminum alloy with beautiful appearance. The silver white surface is full of metallic luster.

Differences In Iron

types of sliding screen door rollers. By adjusting the rollers, you can ensure that the door slides smoothly and closes properly.

Both paint and powder coatings are common solutions, though powder coatings can’t be touched up on site when they chip, which makes them less practical for long term maintenance. we typically hot dip galvanize our wrought iron, which adds a zinc coating to the metal, protecting it from oxidation. We then prime and paint over it for finishing.

1. Remove Obstructions Before making any adjustments, ensure that the area around the sliding door is clear. This includes taking down any curtains or blinds that may interfere with your work.

adjusting rollers on sliding door

Whether it's a casement, sliding, tilt-turn, or fixed window type, aluminium frames can be tailored to fit different architectural styles, sizes, and shapes Whether it's a casement, sliding, tilt-turn, or fixed window type, aluminium frames can be tailored to fit different architectural styles, sizes, and shapes

Whether it's a casement, sliding, tilt-turn, or fixed window type, aluminium frames can be tailored to fit different architectural styles, sizes, and shapes Whether it's a casement, sliding, tilt-turn, or fixed window type, aluminium frames can be tailored to fit different architectural styles, sizes, and shapes aluminium windows profile. They can also be powder-coated in a wide range of colors and finishes to blend seamlessly with the building's exterior or interior design.

aluminium windows profile. They can also be powder-coated in a wide range of colors and finishes to blend seamlessly with the building's exterior or interior design. They are typically easy to install, often requiring just a few screws to attach them securely to the wall They are typically easy to install, often requiring just a few screws to attach them securely to the wall

They are typically easy to install, often requiring just a few screws to attach them securely to the wall They are typically easy to install, often requiring just a few screws to attach them securely to the wall steel thermostat lock box. Once in place, accessing the thermostat remains straightforward, ensuring you can still make necessary adjustments without hassle.

steel thermostat lock box. Once in place, accessing the thermostat remains straightforward, ensuring you can still make necessary adjustments without hassle.Screen doors are essential for maintaining airflow in our homes while keeping out pests. However, over time, the rollers on screen doors can wear out or become damaged, making it difficult to open and close the door smoothly. Fortunately, repairing screen door rollers is a task that can be accomplished with a bit of effort and the right tools. This article will guide you through the repair process, ensuring your screen door functions like new again.

However, the specific environmental impact of each type of iron comes down to differences in processing. Cast iron, made from melting down scrap iron and other alloys, does make use of recycled materials. However, the energy-intensive process of melting and casting iron can have a significant carbon footprint. Cast iron is also more likely to need replacement if damaged, potentially resulting in more frequent material use over time.

However, it is vital to understand only a few grades can provide high quality components.

Our Forged Steel products are expertly crafted to offer both durability and style, making them a timeless addition to any setting. The Cast Iron elements in our collection exude a classic, vintage charm, while our Aluminum pieces offer a lightweight and versatile option for a modern touch.

The number one concern most folks have about an iron fence is rusting. The problem is that a lot of companies throw out a few vague terms you don’t know and assume you won’t ask questions. Even worst, some sites don’t really specify what type (if any) rust protection they have. Galvanization is a time-honored and great way to protect iron and steel from rust. Lots of fence makers will utilize e-coatings to minimize rust. While they can be effective, it is a thinner coating. We prefer hot-dip galvanization for our parts because it encapsulates every surface of the piece inside and out.

The edges are finished with a sophisticated hemstitch detail, adding an elegant touch to your bathroom decor The edges are finished with a sophisticated hemstitch detail, adding an elegant touch to your bathroom decor

The edges are finished with a sophisticated hemstitch detail, adding an elegant touch to your bathroom decor The edges are finished with a sophisticated hemstitch detail, adding an elegant touch to your bathroom decor

Its size ensures it covers a decent surface area without being too big to handle Its size ensures it covers a decent surface area without being too big to handle

Its size ensures it covers a decent surface area without being too big to handle Its size ensures it covers a decent surface area without being too big to handle