...

2025-08-14 20:22

242

A single bed sheet with elastic fitted, also known as a fitted sheet, is designed specifically for single-sized beds. It is distinguished by its elasticized corners and edges, which snugly hug the mattress, ensuring a secure fit and eliminating the annoyance of constant readjustment. The term 'fitted' refers to the elasticized corners that adapt to the contours of the mattress, whether it's thick or thin, providing a tailored fit.

...

2025-08-14 19:59

91

Bed cover designs also have a psychological impact

...

2025-08-14 19:56

286

Elasticated Bed Valance A Timeless Solution for Comfort and Style

...

2025-08-14 19:52

2881

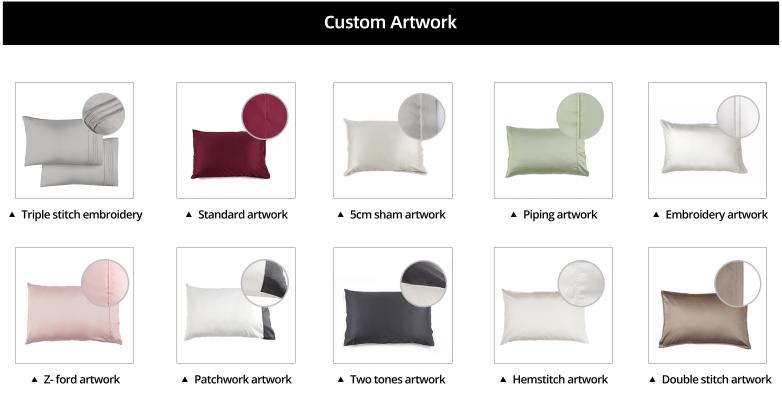

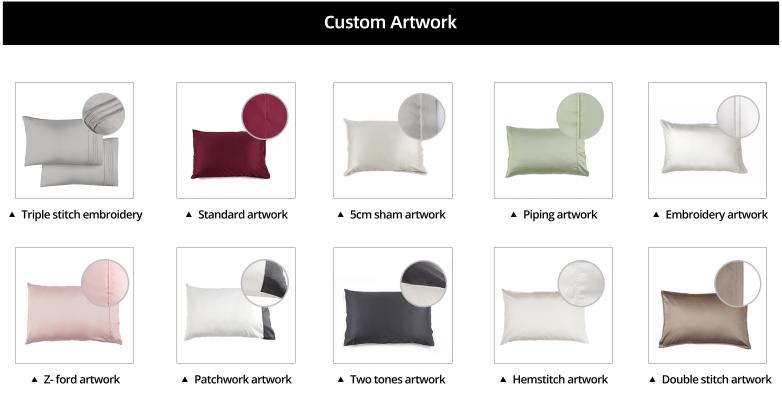

Another influencing factor is the manufacturing process. Sheets with intricate designs, embroidery, or specialized features like anti-bacterial treatment or waterproofing will naturally command a higher price. Moreover, the cost of production, including labor, transportation, and overheads, also contribute to the final price.

...

2025-08-14 19:12

2697

...

2025-08-14 20:22

242

A single bed sheet with elastic fitted, also known as a fitted sheet, is designed specifically for single-sized beds. It is distinguished by its elasticized corners and edges, which snugly hug the mattress, ensuring a secure fit and eliminating the annoyance of constant readjustment. The term 'fitted' refers to the elasticized corners that adapt to the contours of the mattress, whether it's thick or thin, providing a tailored fit.

...

2025-08-14 19:59

91

Bed cover designs also have a psychological impact

...

2025-08-14 19:56

286

Elasticated Bed Valance A Timeless Solution for Comfort and Style

...

2025-08-14 19:52

2881

Another influencing factor is the manufacturing process. Sheets with intricate designs, embroidery, or specialized features like anti-bacterial treatment or waterproofing will naturally command a higher price. Moreover, the cost of production, including labor, transportation, and overheads, also contribute to the final price.

...

2025-08-14 19:12

2697

...

2025-08-14 18:47

2371

This smart technology effectively reduces the number of times you wake up overheated, leading to a more uninterrupted sleep cycle This smart technology effectively reduces the number of times you wake up overheated, leading to a more uninterrupted sleep cycle

This smart technology effectively reduces the number of times you wake up overheated, leading to a more uninterrupted sleep cycle This smart technology effectively reduces the number of times you wake up overheated, leading to a more uninterrupted sleep cycle