- Thrust Ball Bearing Installation A Comprehensive Guide

- Another significant advantage of the 6211 ZZ bearing is its double-sealed design. This feature not only prevents contaminants such as dust and dirt from entering the bearing, but also helps to retain lubricant within the bearing chamber. As a result, the bearing operates smoothly and efficiently, reducing friction and wear, and extending its service life.

- Sealed Tapered Roller Bearings The Ultimate Solution for High Load Capacity and Efficiency

- One of the key advantages of the 6002 rz bearing is its high speed capability. This bearing is designed to operate at high speeds, making it suitable for applications where speed and efficiency are critical. The non-contact seal also helps to reduce friction and heat generation, allowing the bearing to run smoothly and efficiently even at high speeds.

- The 638 ZZ bearing, a precision-engineered component, is renowned for its exceptional performance in various industrial applications. This article delves into the features, benefits, and potential applications of this bearing, highlighting its superior qualities that set it apart from other bearings in the market.

- However, like all mechanical components, the 22326 bearing is not without its challenges. Proper lubrication is essential to ensure longevity and prevent premature failure. Additionally, regular inspection and maintenance are necessary to identify any signs of wear or damage before they become catastrophic.

- Electric Motors and Generators: Bearings are employed in electric motors, generators, and other rotating electrical equipment to support shafts, rotors, and other moving parts, enabling efficient and reliable operation.

- 1. High Load Capacity The 638 ZZ bearing is designed to withstand high radial and axial loads, making it suitable for heavy-duty applications. Its robust construction and precise manufacturing process ensure long-lasting performance and durability.

- When engineers design machinery requiring the use of a 6302 bearing, they must consider these dimensions meticulously. For instance, if the application demands high rotational speeds, the clearance between the inner ring and the shaft becomes critical to prevent excessive heat buildup For instance, if the application demands high rotational speeds, the clearance between the inner ring and the shaft becomes critical to prevent excessive heat buildup

For instance, if the application demands high rotational speeds, the clearance between the inner ring and the shaft becomes critical to prevent excessive heat buildup For instance, if the application demands high rotational speeds, the clearance between the inner ring and the shaft becomes critical to prevent excessive heat buildup

For instance, if the application demands high rotational speeds, the clearance between the inner ring and the shaft becomes critical to prevent excessive heat buildup For instance, if the application demands high rotational speeds, the clearance between the inner ring and the shaft becomes critical to prevent excessive heat buildup bearing 6302 dimensions. Conversely, in heavy-load scenarios, the width and the material properties of the bearing become more important to ensure durability and longevity.

bearing 6302 dimensions. Conversely, in heavy-load scenarios, the width and the material properties of the bearing become more important to ensure durability and longevity. - The quality of the bearing is another crucial factor to consider. High-quality bearings may have a higher price tag, but they are often more durable and have a longer lifespan. It's important to invest in a quality bearing to prevent costly repairs or replacements in the future

30209 bearing price. - When choosing materials for taper roller bearings, engineers must consider several factors, including the operating environment, load conditions, speed requirements, and temperature extremes. Common materials for taper roller bearings include high-carbon chromium steel, stainless steel, ceramics, and various alloys. Each material offers its own set of benefits and drawbacks.

- Thirdly, the market demand for 6307 bearings can influence their price

6307 bearing price. If there is high demand for these bearings, suppliers may increase their prices to capitalize on the market trend. On the other hand, if there is low demand, suppliers may reduce their prices to attract buyers and move inventory.

6307 bearing price. If there is high demand for these bearings, suppliers may increase their prices to capitalize on the market trend. On the other hand, if there is low demand, suppliers may reduce their prices to attract buyers and move inventory. - Cost-Effectiveness

- In conclusion, the 6307 ball bearing, with its robust construction and versatile application, plays a vital role in modern industry. Its widespread use underscores the value placed on precision, durability, and efficiency in engineering solutions. As technology advances, the importance of such components will only continue to grow, shaping the future of mechanical systems and driving innovation across various sectors.

- 1. Quality and Material The quality of a bearing is determined by the materials used in its construction. Higher-quality bearings are typically made from materials like chrome steel, which offer better durability and longevity. These bearings also undergo strict quality control checks, resulting in a higher price tag.

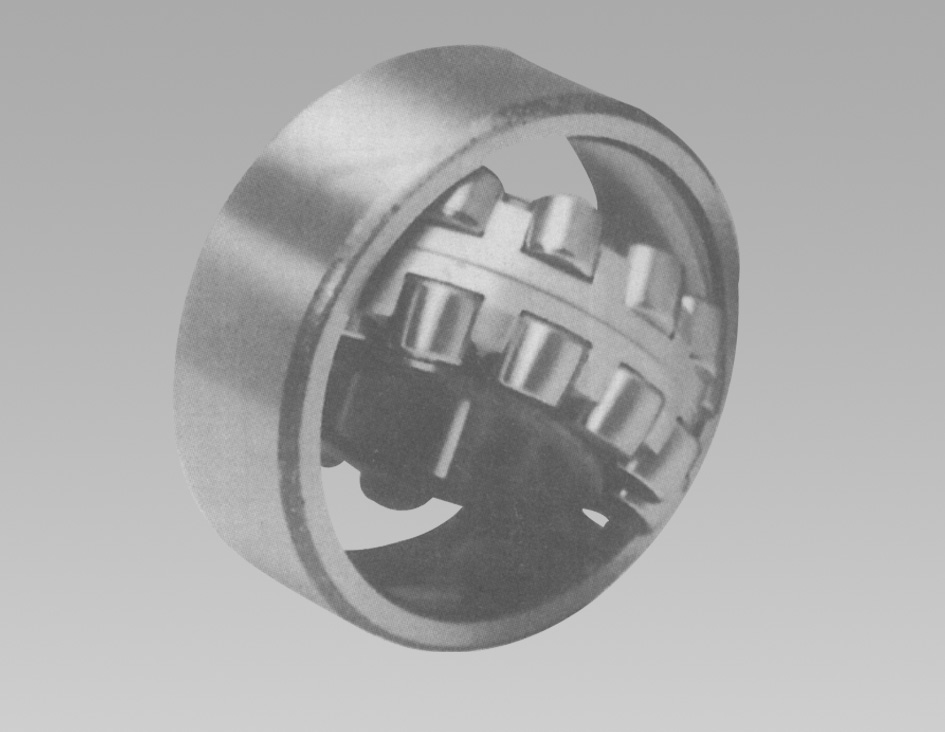

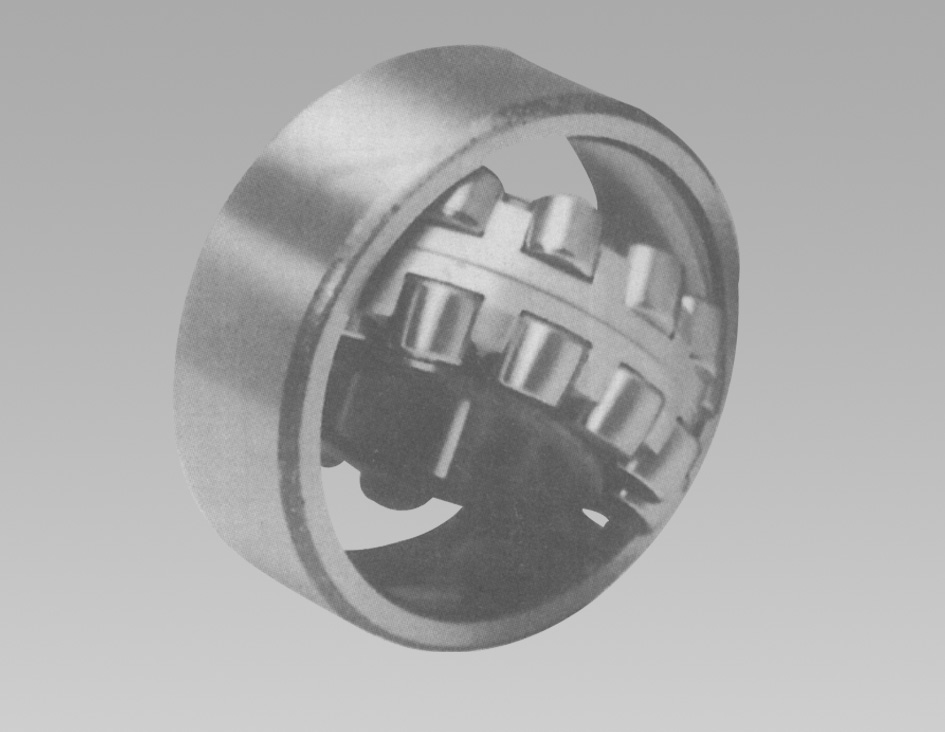

- Mounted spherical roller bearings, an integral component in the world of mechanical engineering, are designed to withstand the rigorous demands of various industrial applications. These bearings, with their unique combination of strength and versatility, have become the go-to solution for numerous industries seeking reliable and efficient machinery operation.

- The versatility of the 638 ZZ bearing makes it suitable for a wide range of applications, including industrial machinery, robotics, and aerospace. Its high load capacity and speed capabilities make it an excellent choice for high-performance applications that demand precision and reliability.

- Finally, the 6903 ZZ bearing is highly cost-effective, with a competitive price point that makes it an attractive option for businesses looking to improve their bottom line. Its durability and performance also mean that users can avoid costly repairs and replacements, further enhancing its cost-effectiveness.

- Conclusion

- Beyond the technical details, the catalog also presents Timken's commitment to sustainability and environmental responsibility. The company's bearings are designed with energy efficiency in mind, contributing to reduced carbon footprints in various industries.

- The 6301 bearing is a superior product that offers unparalleled performance and reliability in various industrial applications. Its unique features, benefits, and wide range of applications make it an indispensable component in modern machinery and equipment. By choosing the 6301 bearing, manufacturers can improve efficiency, reduce maintenance costs, enhance safety, and achieve long-term cost savings.

- Firstly, it is important to understand that bearings come in various shapes and sizes, each designed for a specific application. The dimension '6319' typically refers to a deep groove ball bearing with a particular inner diameter, outer diameter, and width. These measurements must be precise to ensure the bearing fits correctly into its housing and supports the rotating shaft without excessive play or too much friction.

- One of the key reasons behind the success of the 32236 bearing is its superior performance characteristics. These bearings are known for their high load capacity, low friction, and long service life. They are specifically designed to withstand heavy loads and high speeds, making them ideal for use in a wide range of industrial applications.

- It is important to note that the 62211 bearing dimensions may vary slightly depending on the manufacturer and the specific design of the bearing. Therefore, it is essential to refer to the technical specifications provided by the manufacturer to ensure the correct dimensions are used for a particular application.

- When incorporated into machinery, the 6006 2RS bearing becomes an unsung hero

6006 2rs bearing. It might power the rotary movement of a conveyor belt in a factory, spin the wheels of an electric scooter, or even support the rotation of a helicopter's critical components. In each scenario, the bearing operates silently, reliably, and efficiently, often going unnoticed by those who benefit from its functionality.

6006 2rs bearing. It might power the rotary movement of a conveyor belt in a factory, spin the wheels of an electric scooter, or even support the rotation of a helicopter's critical components. In each scenario, the bearing operates silently, reliably, and efficiently, often going unnoticed by those who benefit from its functionality. - Introduction

- Similarly, the width and thickness of a bearing also play a crucial role in its performance. A wider bearing provides more surface area for the lubricant to spread, reducing friction and wear A wider bearing provides more surface area for the lubricant to spread, reducing friction and wear

A wider bearing provides more surface area for the lubricant to spread, reducing friction and wear A wider bearing provides more surface area for the lubricant to spread, reducing friction and wear

A wider bearing provides more surface area for the lubricant to spread, reducing friction and wear A wider bearing provides more surface area for the lubricant to spread, reducing friction and wear 62201 bearing dimensions. In contrast, a narrower bearing may be more susceptible to wear and tear due to increased friction. The thickness of the bearing also affects its load capacity, with thicker bearings being able to support more weight than thinner ones.

62201 bearing dimensions. In contrast, a narrower bearing may be more susceptible to wear and tear due to increased friction. The thickness of the bearing also affects its load capacity, with thicker bearings being able to support more weight than thinner ones. - NSK, on the other hand, focuses on innovation and sustainability

- To use the size chart, simply find the bearing that meets your requirements based on the relevant dimensions and specifications. For example, if you need a bearing with a bore diameter of 50 mm and a maximum load capacity of 10 kN, you would look for a bearing that falls within the appropriate range on the size chart.

- * Sealed design The 6310 RS bearing features a sealed design that prevents dirt and debris from entering the bearing, extending its life and maintaining performance.

- The 29338 bearing is a high-performance bearing designed to withstand extreme conditions while maintaining optimal efficiency. Its unique design allows it to handle heavy loads and high speeds, making it ideal for use in demanding environments such as automotive manufacturing, aerospace engineering, and industrial machinery.

- In addition to their high load capacity, taper roller bearings also offer excellent performance at high speeds

- Unique Features of 24052 Bearings

- Another important feature of cylindrical roller bearings is their ability to withstand heavy loads

- The size chart typically includes the following information

- Tapered roller bearings are commonly used in various industrial applications due to their ability to support heavy radial and axial loads. One of the best types of tapered roller bearings available in the market today is the best tapered roller bearings. These bearings are known for their high quality and excellent performance, making them a top choice for many industries.

- Bearing size plays a crucial role in the performance and longevity of machinery. It is a critical component that ensures smooth operation and reduces friction between moving parts. A bearing's size is determined by its inner diameter (ID), outer diameter (OD), and width. These dimensions affect the load capacity, speed rating, and overall size of the bearing.

- Versatility: Cylindrical roller bearings are used in a wide range of industries and applications, including automotive, aerospace, industrial machinery, and power generation, due to their versatility and load-carrying capabilities.

- Lastly, these bearings offer excellent speed capabilities. With proper lubrication, they can operate at high speeds without compromising on performance or safety. This versatility makes them suitable for both low-speed and high-speed applications.

- The 6004Z bearing, classified as a deep groove ball bearing, features a single row design with a shield on one side to protect against dust and debris. Its dimensions, with an inner diameter of 20mm, outer diameter of 47mm, and width of 12mm, make it suitable for numerous industrial applications including motorcycles, electric motors, and office equipment.

- The 6303 bearing falls under the category of deep groove ball bearings, a type renowned for their ability to handle both radial and axial loads. The '6303' designation is derived from the ISO dimension series, where '6' signifies a single row deep groove ball bearing, and '303' denotes the specific dimensions of the inner and outer rings, balls, and cage assembly.

- Overall, the taper bearing ID and OD chart is an essential reference tool for anyone working with taper bearings. Whether selecting a bearing for a new application or troubleshooting an existing system, this chart provides the necessary information to make informed decisions. By leveraging the information in the chart, users can ensure the reliable performance and longevity of their mechanical systems.

- In conclusion, conical roller bearings are a versatile and reliable solution for various industrial applications. Their high load capacity, high speed operation, compact size, and long life make them an excellent choice for machinery that requires superior performance and reliability. As technology continues to advance, we can expect to see further improvements and innovations in conical roller bearings, making them an even more indispensable component in modern machinery design.

- The taper ratio of these bearings typically ranges from 112 to 130, allowing for a balance between load distribution and load capacity

bearing id 80 od 140 taper roller. In the case of a bearing with ID 80mm and OD 140mm, the specific taper ratio would be specified by the manufacturer, influencing its load-carrying capability and operational efficiency.

bearing id 80 od 140 taper roller. In the case of a bearing with ID 80mm and OD 140mm, the specific taper ratio would be specified by the manufacturer, influencing its load-carrying capability and operational efficiency.

The feel of crisp, clean sheets can make a significant difference in how well a traveler sleeps, especially after a long journey The feel of crisp, clean sheets can make a significant difference in how well a traveler sleeps, especially after a long journey

The feel of crisp, clean sheets can make a significant difference in how well a traveler sleeps, especially after a long journey The feel of crisp, clean sheets can make a significant difference in how well a traveler sleeps, especially after a long journey For instance, if the application demands high rotational speeds, the clearance between the inner ring and the shaft becomes critical to prevent excessive heat buildup For instance, if the application demands high rotational speeds, the clearance between the inner ring and the shaft becomes critical to prevent excessive heat buildup

For instance, if the application demands high rotational speeds, the clearance between the inner ring and the shaft becomes critical to prevent excessive heat buildup For instance, if the application demands high rotational speeds, the clearance between the inner ring and the shaft becomes critical to prevent excessive heat buildup

A wider bearing provides more surface area for the lubricant to spread, reducing friction and wear A wider bearing provides more surface area for the lubricant to spread, reducing friction and wear

A wider bearing provides more surface area for the lubricant to spread, reducing friction and wear A wider bearing provides more surface area for the lubricant to spread, reducing friction and wear