...

2025-08-14 13:58

2320

But we don't just stop at quality; we also offer unbeatable prices

...

2025-08-14 13:57

2238

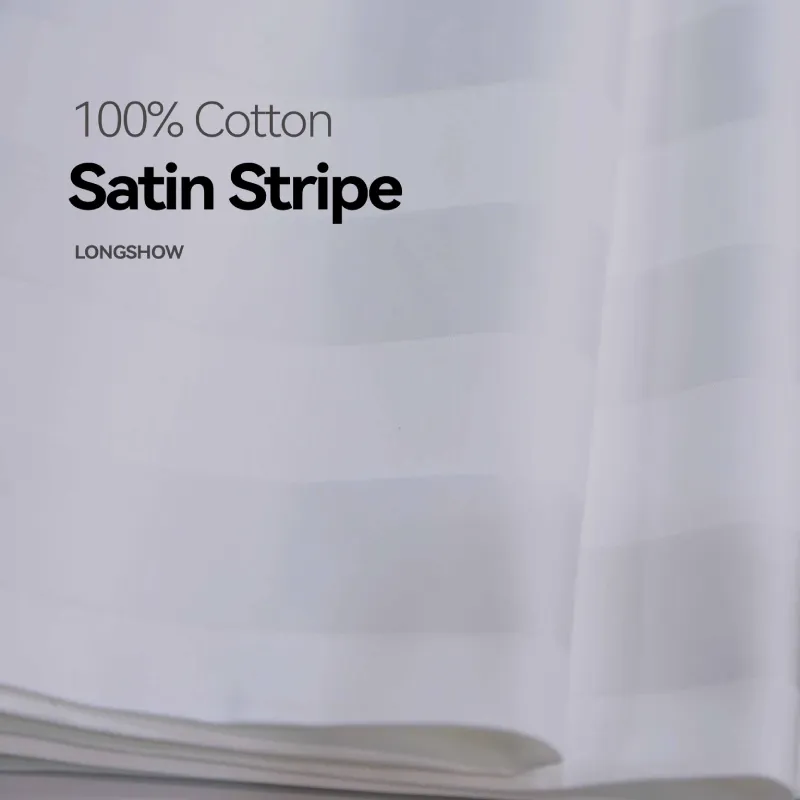

Cotton, being a natural fiber, is the preferred choice for hospital bedding due to its numerous benefits. Firstly, cotton is highly breathable, allowing air to circulate freely, which is crucial in maintaining a comfortable temperature for patients, especially those who might be confined to bed for extended periods. It helps wick away moisture, preventing excessive sweating and ensuring a cool and dry sleeping surface, thereby reducing the risk of skin irritations and infections.

...

2025-08-14 13:47

2687