...

2025-08-15 18:36

2072

...

2025-08-15 18:23

683

...

2025-08-15 18:04

2832

...

2025-08-15 17:18

934

...

2025-08-15 17:03

1323

...

2025-08-15 16:42

603

...

2025-08-15 16:30

1293

...

2025-08-15 16:29

1995

...

2025-08-15 16:24

1444

...

2025-08-15 16:20

648

These gaskets are often made from flexible rubber compounds that can withstand the pressure and temperature variations common in plumbing applications These gaskets are often made from flexible rubber compounds that can withstand the pressure and temperature variations common in plumbing applications

These gaskets are often made from flexible rubber compounds that can withstand the pressure and temperature variations common in plumbing applications These gaskets are often made from flexible rubber compounds that can withstand the pressure and temperature variations common in plumbing applications thin rubber gasket.

thin rubber gasket.There are several key factors to consider when you are selecting the oil seals for your next project to ensure that you protect your machinery from immediate and long-term damage.

OIL SEAL (LIP SEAL) VS. MECHANICAL SEAL: PROS & CONS OF EACH

Rubber type

black spark plug. This increased durability can result in fewer maintenance issues and a more reliable engine overall.

1. Clean the Surface

ordinary fluorine rubber, but are 10 times as high as fluorine rubber.

If you follow the above instructions, the oil seals should work properly. Also watch the video below for an example of the installation process.

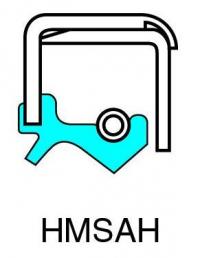

The construction of an oil seal is a testament to meticulous engineering. Each oil seal primarily comprises two core components: the sealing element and the metal case. The collaboration of these parts brings about the seal’s functionality and effectiveness. A garter spring may also be included as an available feature, providing an extra layer of operational support.