3

There are several different types of materials that can be used to make a wiring loom wrap, including plastic, fabric, and tape

. Each material has its own set of advantages and disadvantages, depending on the specific requirements of the vehicle and its environment.automotive wiring loom wrap

safety floor tape. In high-risk areas where special precautions are necessary, safety floor tape can be used to clearly mark off these areas and prevent unauthorized access.

The car harness tape is a type of adhesive tape that is specifically designed to secure and protect the wiring harnesses in your car. These harnesses are responsible for connecting various electrical components in your vehicle, such as lights, sensors, and the engine control unit.

Amalgamating tape is a great alternative to traditional sealing methods such as glue, caulk, or silicone. It is flexible, durable, and can withstand a wide range of temperatures and environments. Whether you are repairing a leaky pipe, sealing an electrical connection, or fixing a broken hose, amalgamating tape is a reliable solution.

Silicone tape is renowned for its waterproof properties. It is an ideal solution for sealing leaks in boats, outdoor equipment, or even temporarily fixing damaged gutters during heavy rain.

Generally speaking, manufacturers use three different adhesive types in combination with the backing material to produce a final “tape” product. Though these adhesive types can be subdivided into subgroups, the main categories are as follows:

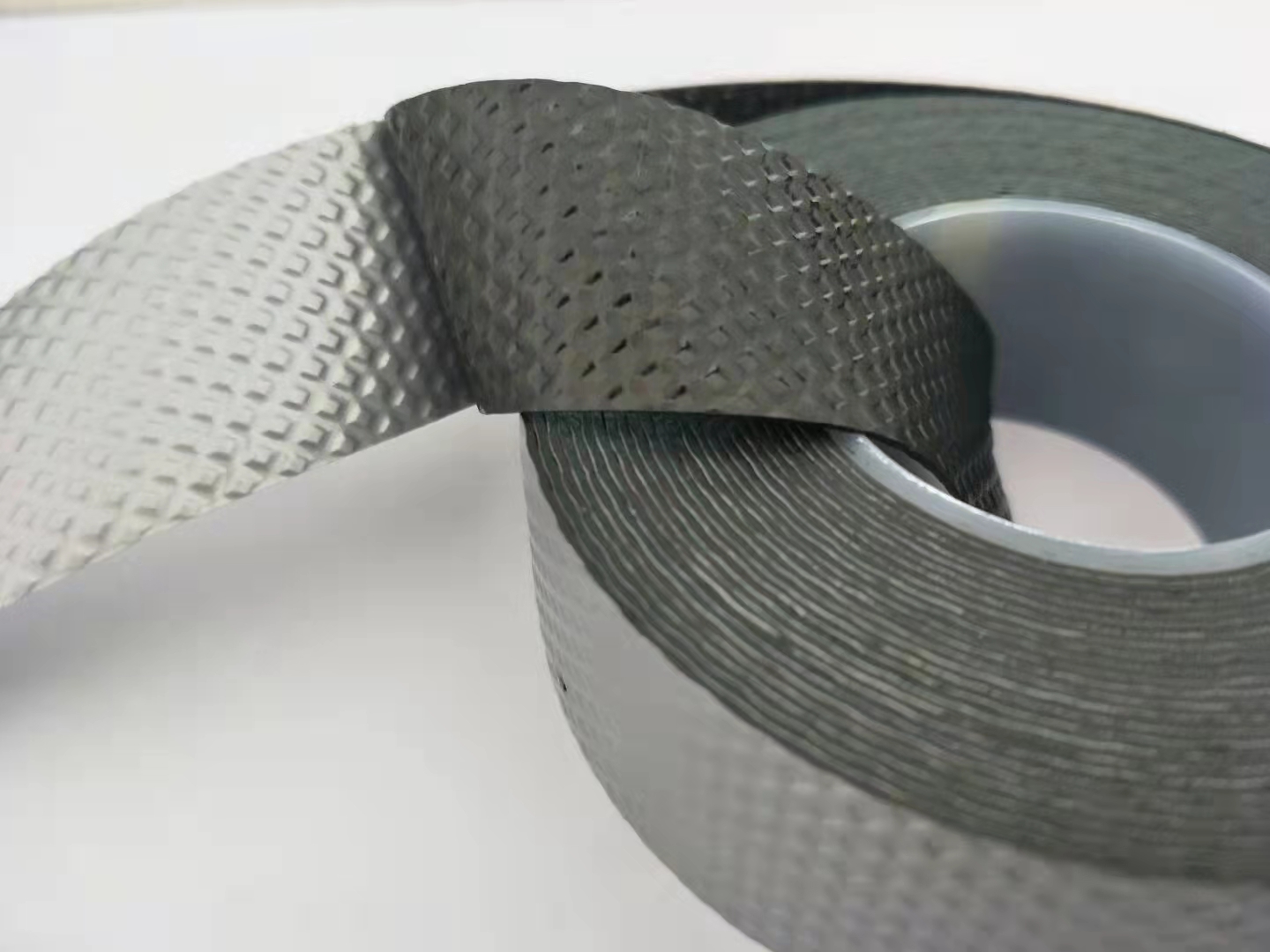

adhesive cloth automotive wiring harness tape. Durability The combination of a cloth backing and a strong adhesive layer makes this tape highly resistant to wear and tear. It can withstand extreme temperatures, vibrations, and other harsh conditions commonly encountered in automotive environments.

adhesive cloth automotive wiring harness tape. Durability The combination of a cloth backing and a strong adhesive layer makes this tape highly resistant to wear and tear. It can withstand extreme temperatures, vibrations, and other harsh conditions commonly encountered in automotive environments.Insulating tape is also commonly used for temporary repairs. In emergency situations where wires are damaged or exposed, insulating tape can be used to quickly cover and protect them until a permanent solution can be implemented. This can help to prevent further damage and ensure that the electrical system stays operational.

- Power Plants In electricity generation facilities, insulation tape is critical for securing connections and protecting sensitive components from high voltage electricity.

Its resistance to temperature fluctuations, vibrations, and chemicals makes it an ideal choice for ensuring a secure and long-lasting seal Its resistance to temperature fluctuations, vibrations, and chemicals makes it an ideal choice for ensuring a secure and long-lasting seal

Its resistance to temperature fluctuations, vibrations, and chemicals makes it an ideal choice for ensuring a secure and long-lasting seal Its resistance to temperature fluctuations, vibrations, and chemicals makes it an ideal choice for ensuring a secure and long-lasting seal butyl rubber sealant black.

butyl rubber sealant black. insulation cotton tape. Its gentle nature makes it suitable for sensitive skin, and the cotton material promotes air circulation, aiding in injury recovery. Furthermore, its insulating properties can help regulate body temperature during rehabilitation processes.

insulation cotton tape. Its gentle nature makes it suitable for sensitive skin, and the cotton material promotes air circulation, aiding in injury recovery. Furthermore, its insulating properties can help regulate body temperature during rehabilitation processes.Furthermore, silicone insulation tape is available in various colors and widths, which can be beneficial for color-coding applications or ensuring visibility in complex electrical systems. This versatility allows users to choose the most suitable tape for their specific project requirements.