หนึ่งในข้อดีของการใช้สายเชื่อมแบบเคลือบสังกะสี คือมีน้ำหนักเบาและง่ายต่อการติดตั้ง ซึ่งช่วยประหยัดเวลาในกระบวนการก่อสร้าง นอกจากนี้ยังช่วยลดต้นทุนในการบำรุงรักษาในระยะยาว เนื่องจากไม่ต้องดำเนินการป้องกันสนิมหรือเปลี่ยนสายเชื่อมบ่อยครั้งเมื่อเปรียบเทียบกับสายเชื่อมที่ผลิตจากโลหะทั่วไป

galvanized brick ties

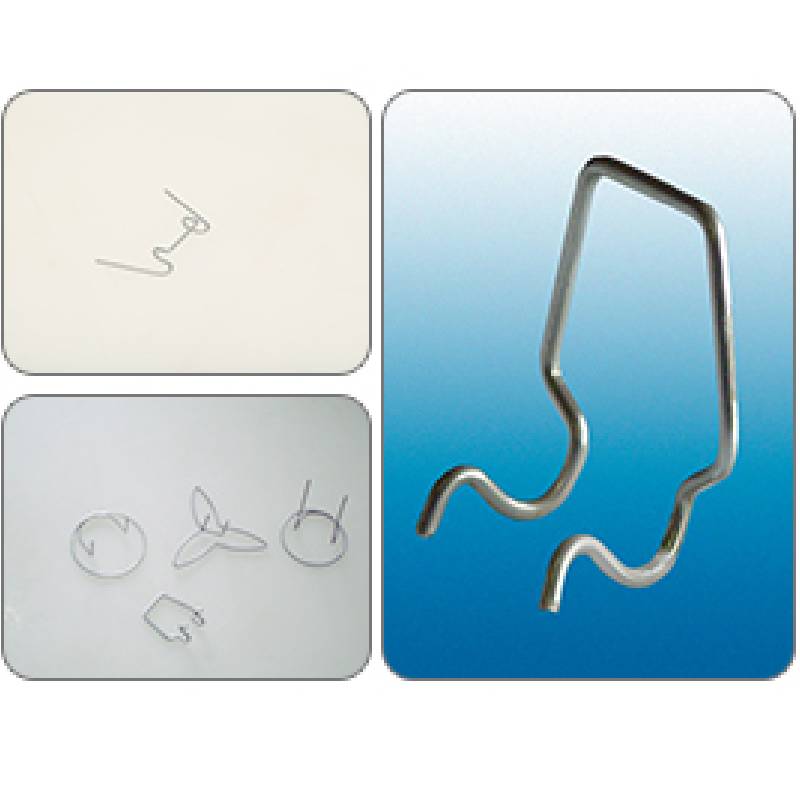

Corrugated brick ties are metal connectors designed to bond brickwork with the underlying structural framework, such as concrete or steel. Their unique corrugated design provides increased surface area, which enhances their strength and ability to resist shear forces—vital characteristics in ensuring the stability of brick walls. Unlike traditional flat ties, the corrugated design allows for better load distribution and is less prone to buckling under pressure.

The spring rate, or stiffness, indicates how a spring will perform under load. It is defined as the amount of load required to compress the spring by a unit of length. In heavy-duty applications, selecting a spring with the correct spring rate is essential to ensure that the spring can absorb the required forces without compromising its structural integrity or functionality. A higher spring rate indicates a stiffer spring, which is beneficial for applications involving heavy loads, but it must be balanced with the need for flexibility and shock absorption.

Welded wire spacers are essential for maintaining the correct spacing between concrete blocks during construction. These spacers, made from durable welded wire, ensure that the blocks are evenly spaced and properly aligned. The uniformity provided by welded wire spacers is crucial for achieving consistent grout or mortar application, which in turn affects the overall structural integrity of the wall. When choosing welded wire spacers, consider factors such as wire thickness, spacing requirements, and the specific needs of your construction project to ensure optimal performance.

Heat Treatment –Cold winding begins withheat treatmentof the wire or working to reach its highest strength level. The process of cold winding can only work with wires that have a diameter of 0.75 inches or 18 mm or less.

Design Considerations for Compression Coil Springs

Galvanoitu Hitsattu Langaverkko Kestävä ja monipuolinen ratkaisu

We deliver manufactured metal spring samples so that you can test them in real-world applications. This guarantees that you are happy with the spring and that it is reaching optimal performance before going into production.

Coil Spring

Due to their robust nature, 20mm compression springs find extensive applications across multiple industries, including automotive, aerospace, electronics, and manufacturing

.Applications

Joint Reinforcement in Masonry

Conclusion

Rodzaje łączników ścian blokowych

For one thing, without the insert, the duvet cover may not provide as much warmth or insulation as it would with the insert For one thing, without the insert, the duvet cover may not provide as much warmth or insulation as it would with the insert

For one thing, without the insert, the duvet cover may not provide as much warmth or insulation as it would with the insert For one thing, without the insert, the duvet cover may not provide as much warmth or insulation as it would with the insert