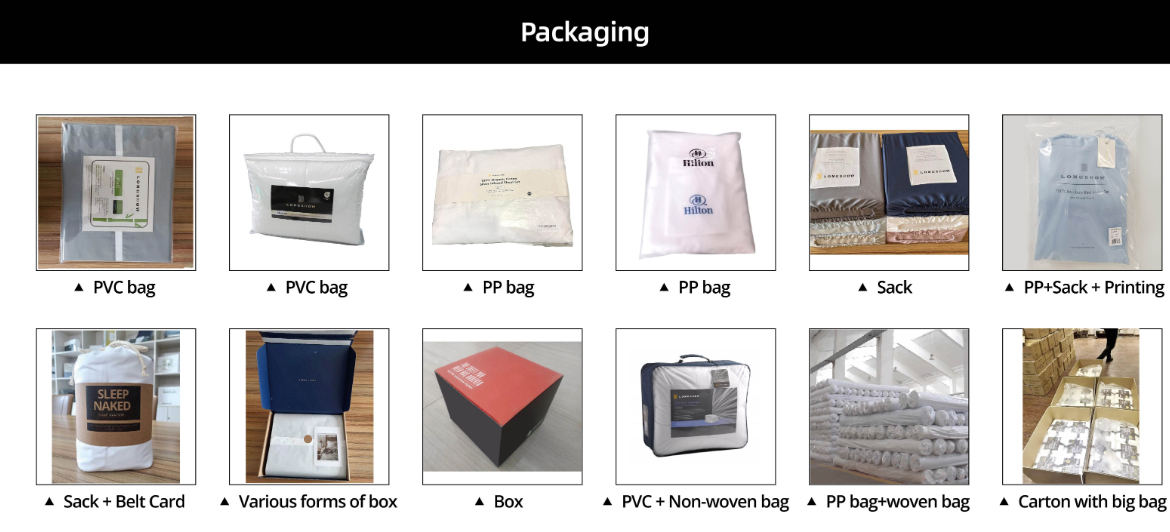

The presentation of a towel gift set can elevate its appeal even further

Oil seals, often called a rotary shaft seal or grease seal, closes the gap between stationary and moving components in mechanical equipment — most often rotating shafts — helping prevent lubricant escape and stopping harmful materials, such as dirt, from moving in through the clearance. Oil seals are most commonly used in gearboxes, hydraulic cylinders, and related components.

Installation techniques must be carefully selected and executed to ensure the seal functions correctly throughout its service life. Each technique addresses specific installation needs and ensures long-term reliablity.

In the UK, customers have a range of options for purchasing oil seals. There are several reputable UK gasket manufacturers that offer a wide selection of oil seals to meet various industrial needs.

JTEKT provides special seals for use in a wide variety of machines and applications.

Table 5 lists the major special seals, their shapes, and their features.

Figure 14.1. Shaft seals (DuPont Dow Elastomers).

silicone oil seal. They can be tailored to meet specific requirements, whether it's customizing the hardness, shape, or size to fit unique applications. They can be used in static or dynamic sealing situations, sealing everything from hydraulic fluids to aggressive solvents.

silicone oil seal. They can be tailored to meet specific requirements, whether it's customizing the hardness, shape, or size to fit unique applications. They can be used in static or dynamic sealing situations, sealing everything from hydraulic fluids to aggressive solvents. Engineers showcased how it could optimize fuel consumption, leading to better fuel economy and reduced emissions – a timely solution amidst growing environmental concerns Engineers showcased how it could optimize fuel consumption, leading to better fuel economy and reduced emissions – a timely solution amidst growing environmental concerns

Engineers showcased how it could optimize fuel consumption, leading to better fuel economy and reduced emissions – a timely solution amidst growing environmental concerns Engineers showcased how it could optimize fuel consumption, leading to better fuel economy and reduced emissions – a timely solution amidst growing environmental concerns e3 12 spark plug. The audience was captivated as they witnessed the tangible impact of this innovation on engine performance, witnessing smoother starts, faster acceleration, and quieter operations.

e3 12 spark plug. The audience was captivated as they witnessed the tangible impact of this innovation on engine performance, witnessing smoother starts, faster acceleration, and quieter operations.Coat the sump flange with gasket-sealant and fit the flat parts of the gasket to it, ensuring that they are exactly positioned and joined.

Table 5: Major rubber materials and their operational temperature ranges

No code: without minor lip

Shaft and Bore Tolerance

Our suppliers try to provide the best quality oil seals and products are in some cases optimised to improve performance and fitment. Corteco is one of these brands, whose case studies we have listed for you.

Oil seals made of HNBR are characterised by excellent properties that include high resistance to mineral oils with additives, low steam and gas permeability, good cold flexibility down to -30 °C depending on type, good ozone resistance and friction resistance. HNBR seals withstand heat up to 150°C.

They also feature a good electrode gap, which determines the distance between the center electrode and the spark plug's outer shell They also feature a good electrode gap, which determines the distance between the center electrode and the spark plug's outer shell

They also feature a good electrode gap, which determines the distance between the center electrode and the spark plug's outer shell They also feature a good electrode gap, which determines the distance between the center electrode and the spark plug's outer shell truck spark plugs. A smaller gap results in a higher voltage and thus a more effective spark, while a larger gap provides a longer life to the spark plug.

truck spark plugs. A smaller gap results in a higher voltage and thus a more effective spark, while a larger gap provides a longer life to the spark plug. oil seal 20 40 7. Different oils have different properties, such as viscosity and chemical composition, which can affect the performance of the seal. It is essential to choose a seal that is specifically designed to work with the oil being used in the application.

oil seal 20 40 7. Different oils have different properties, such as viscosity and chemical composition, which can affect the performance of the seal. It is essential to choose a seal that is specifically designed to work with the oil being used in the application.