Premium Absorbent Towel for Bath | Soft Bathroom Linen

In the realm of bathroom linen, the **towel for bath** stands as a quintessential item, embodying comfort, hygiene, and luxury. More than just a utility, a high-quality **towel for bath** enhances daily rituals, transforming a simple shower into a spa-like experience. This comprehensive guide delves into the intricate world of bath towels, covering everything from industry trends and technical specifications to manufacturing processes, application scenarios, and expert tips for selection and care. We aim to provide unparalleled insights, ensuring you make informed decisions whether for personal use, hospitality, or healthcare.

Fig 1: A display showcasing the diverse textures and colors of modern bath towels, reflecting current industry trends in bathroom linen.

Current Industry Trends and Market Dynamics in Bathroom Linen

The global market for **bathroom linen**, particularly **towel for bath** products, is experiencing dynamic shifts driven by consumer preferences for sustainability, luxury, and smart technologies. The market size for towels alone was valued at approximately USD 11.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of over 5% from 2023 to 2030, according to reports from Grand View Research. Key trends include:

- Sustainability and Eco-Friendliness: Growing demand for organic cotton, bamboo, recycled materials, and OEKO-TEX certified products signifies a shift towards environmentally conscious consumption. Manufacturers are increasingly adopting sustainable production practices to reduce water and energy consumption.

- Premiumization and Luxury: Consumers are willing to invest more in high-quality, ultra-soft, and highly absorbent towels, viewing them as an affordable luxury. This drives demand for towels made from premium materials like Egyptian or Pima cotton with higher GSM (Grams per Square Meter).

- Technological Innovations: Advances in textile technology have led to quick-drying, antimicrobial, and even self-cleaning **towel for bath** options. These innovations enhance convenience and hygiene, particularly appealing to hospitality and healthcare sectors.

- Personalization and Customization: The desire for unique home decor and branded experiences fuels the demand for custom embroidered, jacquard woven, and color-matched towels for both residential and commercial clients.

- Digital Retail Growth: E-commerce platforms have become pivotal distribution channels, offering consumers wider selections and competitive pricing, while enabling brands to reach global audiences directly.

Understanding the Core: What Makes a Superior Towel for Bath?

The quality of a **towel for bath** is determined by several critical factors, primarily its material composition, weave type, and technical specifications. Understanding these elements is crucial for evaluating performance and durability.

Materials Deep Dive: The Foundation of Feel and Function

The choice of material significantly impacts a towel's absorbency, softness, and drying speed:

- Cotton: The most popular choice, renowned for its absorbency and softness.

- Egyptian Cotton: Known for its extra-long staple fibers, producing incredibly soft, strong, and highly absorbent towels. Ideal for luxury **bath towel** and hotel use.

- Pima Cotton (Supima): Similar to Egyptian cotton, with long staples that yield strong, soft, and durable fabrics.

- Turkish Cotton: Features longer fibers than standard cotton but shorter than Egyptian, resulting in a balance of absorbency and a quicker drying time, making it excellent for a fluffy, soft **towel for bath**.

- Upland Cotton: The most common type, with shorter fibers, offering good absorbency but less softness and durability compared to long-staple varieties.

- Organic Cotton: Grown without synthetic pesticides or fertilizers, certified by standards like GOTS (Global Organic Textile Standard), appealing to eco-conscious consumers.

- Microfiber: A synthetic blend, typically polyester and polyamide. Highly absorbent, quick-drying, and lightweight. Excellent for travel and athletic use, but may not offer the same luxurious feel as cotton.

- Bamboo: Made from bamboo cellulose, known for its exceptional softness, natural antimicrobial properties, and high absorbency. It's also biodegradable and sustainable.

- Linen Blends: Often blended with cotton, linen provides a crisp texture, excellent absorbency, and quick-drying properties. Known for durability and a slightly rustic aesthetic.

Fig 2: Close-up view of various towel textures, highlighting the distinct feel and appearance derived from different materials and weave types, crucial for a high-quality **bath towel**.

Technical Parameters & Specifications: Quantifying Quality

Beyond material, several technical parameters define a towel's performance:

- GSM (Grams per Square Meter): This measures the density of the fabric.

- 300-400 GSM: Lighter, quicker drying, suitable for gym towels or **wash cloth**.

- 400-600 GSM: Mid-range, good balance of absorbency and drying time, common for everyday **bath towel**.

- 600-900+ GSM: Denser, heavier, highly absorbent, and luxurious, typical of premium hotel towels or high-end **towel for bath**.

- Pile Height: Refers to the length of the loops on a terry towel. Longer loops mean more surface area for absorbency and a softer feel.

- Weave Type:

- Terry: The most common, characterized by looped pile that stands away from the base, maximizing surface area for absorbency.

- Waffle: Features a honeycomb-like weave, creating pockets that increase absorbency while remaining lightweight and quick-drying.

- Velour: Terry loops are sheared, resulting in a smooth, plush, velvet-like surface. Less absorbent than traditional terry but offers a luxurious feel, often used for beach towels or decorative **bathroom linen**.

- Jacquard: Incorporates intricate woven patterns or logos directly into the fabric, providing a premium, customized look for **towel for bath**.

- Dye Fastness: The ability of the dye to resist fading or bleeding when exposed to washing, light, or sweat. Measured by standards like ISO 105.

- Shrinkage Rate: The percentage a fabric shrinks after washing. High-quality towels are pre-shrunk or designed to minimize shrinkage, typically below 5%.

Towel for Bath Parameter Comparison Table

| Parameter | Standard Terry (450 GSM) | Luxury Egyptian Cotton (700 GSM) | Bamboo Blend (500 GSM) | Microfiber (350 GSM) |

|---|---|---|---|---|

| Material | Upland Cotton | Egyptian Cotton (Extra-Long Staple) | Bamboo Viscose / Cotton Blend | Polyester / Polyamide |

| Feel/Softness | Soft, Absorbent | Ultra-Soft, Plush, Luxurious | Silky Soft, Hypoallergenic | Smooth, Slightly Synthetic |

| Absorbency Rate | Good | Excellent | Exceptional | Very High |

| Drying Time | Moderate | Slow (due to density) | Fast | Very Fast |

| Durability | Good | Excellent, Long-Lasting | Good, if cared for | Very Good, Resists Wear |

| Typical Use | Everyday **bath towel** | Luxury Hotels, Spas, Premium Home Use | Sensitive Skin, Eco-Conscious, Quick Dry | Sports, Travel, Cleaning, Quick Dry |

| Price Point | Entry-Mid | High | Mid-High | Mid |

The Journey from Fiber to Fluff: Manufacturing Process of a Towel for Bath

The creation of a high-quality **towel for bath** is a meticulous process involving several stages, each crucial for the final product's performance and feel. This journey ensures durability, absorbency, and softness.

Fig 3: An industrial loom in operation, illustrating the intricate weaving process that creates the characteristic loops of a terry **towel for bath**.

Detailed Manufacturing Process Flow:

-

1

Fiber Selection & Preparation: Raw fibers (e.g., raw cotton bales) are rigorously selected based on staple length, fineness, and purity. These fibers are then cleaned to remove impurities and "carded" – a process that aligns the fibers into a continuous web. For premium towels, "combing" is an additional step that removes shorter fibers, resulting in a smoother, stronger yarn.

-

2

Spinning: The prepared fibers are spun into yarn. Common spinning methods include "ring-spun" (creates finer, softer, and stronger yarn due to tighter twists) and "open-end spun" (produces bulkier, faster-drying yarn). The yarn's twist level influences its strength and absorbency.

-

3

Warping & Sizing: Yarns destined for the length of the fabric (warp yarns) are wound onto large beams. They are then treated with a "sizing" agent (a protective coating) to increase their strength and reduce friction during weaving, preventing breakage.

-

4

Weaving: This is the core of towel production. Terry towels are woven on specialized looms that create loops. Two sets of warp yarns are used: the ground warp (forms the base fabric) and the pile warp (forms the loops). Weft yarns interlace horizontally. The density and height of these loops directly impact the towel's absorbency and plushness.

Illustration of Terry Weaving (Conceptual):

Ground Warp (tensioned) → Weft Insertion → Pile Warp (slack, forms loops) ↑ ↑ ↑ Loom Mechanism Yarn Interlacing Loop Formation -

5

Pre-treatment (Scouring & Bleaching): The woven grey fabric undergoes scouring to remove natural impurities, oils, and sizing agents. It is then bleached (often with hydrogen peroxide) to achieve a uniform white base, which is crucial for subsequent dyeing or for maintaining pristine white **wash cloth** or **bath towel** used in hotels.

-

6

Dyeing: If colored towels are desired, the fabric is dyed using various methods (e.g., reactive dyeing for vibrant, fade-resistant colors; vat dyeing for excellent fastness). Precise temperature and chemical control ensure uniform color penetration and excellent dye fastness, meeting standards like ISO 105.

-

7

Finishing: This stage enhances the towel's tactile properties.

- Softening: Application of fabric softeners for a luxurious feel.

- Shearing (for Velour): Loops are cut to create a smooth, velvety surface.

- Drying: Fabrics are dried, often in large tumble dryers to fluff up the loops.

- Sanforizing/Compacting: A mechanical process that pre-shrinks the fabric, minimizing further shrinkage after consumer washing and enhancing dimensional stability.

-

8

Cutting, Hemming & Stitching: Large rolls of finished fabric are cut into individual towel sizes. Edges are then hemmed and stitched using robust double-stitched seams to prevent fraying and ensure durability, especially important for hospitality-grade **towel for bath** that undergo frequent commercial laundering.

-

9

Final Inspection & Packaging: Each **towel for bath** undergoes a thorough quality inspection to check for defects, ensure consistent size, weight, color, and finish. Only products meeting stringent quality control standards (e.g., AQL - Acceptable Quality Limit) are packaged for shipment.

Rigorous Quality Control & Industry Standards for Towel for Bath

Ensuring the longevity and performance of a **towel for bath** requires adherence to strict quality control measures throughout its production. Leading manufacturers follow internationally recognized standards to guarantee product excellence and safety.

Fig 4: A quality assurance technician meticulously inspecting a batch of **bath towel** for consistency in color, weave, and finishing, a critical step in maintaining high standards.

Key Testing and Certification Standards:

- OEKO-TEX Standard 100: This is a global standard for independently testing raw, semi-finished, and finished textile products for harmful substances. Certification ensures the **towel for bath** is safe for human use, free from hundreds of chemicals known to be harmful, making it ideal for sensitive skin and children.

- ISO 9001: While not specific to towels, ISO 9001 certifies the manufacturer's Quality Management System (QMS). A factory with ISO 9001 certification demonstrates a commitment to consistent product quality, customer satisfaction, and continuous improvement in its production processes.

- AATCC (American Association of Textile Chemists and Colorists) & ISO 105: These standards govern colorfastness tests. They ensure that the towel's color will not bleed or fade significantly after washing, exposure to light, or rubbing. Key tests include:

- AATCC Test Method 8: Colorfastness to Crocking (Rubbing): Measures color transfer when rubbed.

- ISO 105-C06: Colour fastness to domestic and commercial laundering: Assesses color change and staining during washing.

- ISO 105-B02: Colour fastness to artificial light: Evaluates resistance to fading from light exposure.

- ASTM D1117 / ISO 9073: These standards relate to the absorbency and dimensional stability (shrinkage) of textile fabrics. Absorbency tests measure how quickly and how much water a **wash cloth** or **bath towel** can absorb. Dimensional stability tests ensure the towel retains its size and shape after multiple washes, crucial for commercial laundry environments.

- Fiber Content Labeling (e.g., FTC standards in the US): Ensures accurate disclosure of fiber composition, allowing consumers to make informed choices.

By adhering to these rigorous standards, manufacturers provide robust, high-performance **towel for bath** products that meet global expectations for quality, safety, and durability.

Lifespan & Durability: Investing in Quality

The lifespan of a **towel for bath** is a critical factor, especially for commercial applications where frequent laundering is common. A high-quality towel, though potentially a higher initial investment, offers superior longevity and maintains its aesthetic and functional properties over hundreds of washes, yielding a lower total cost of ownership.

- Material Quality: Long-staple cottons (Egyptian, Pima) are inherently more durable as their longer fibers reduce shedding and pilling.

- Weave Strength: Densely woven terry with strong base weaves and double-stitched hems significantly resist wear and tear.

- Dye Quality: High-quality, reactive dyes are more resistant to fading and chemical degradation from detergents and bleach, preserving the towel's appearance.

- Care Practices: Proper washing, drying, and avoiding harsh chemicals (like excessive bleach) can significantly extend a towel's life.

For example, a premium 700 GSM hotel-grade **bath towel** can maintain its integrity and absorbency for 200-300 commercial washes, whereas a lower quality 400 GSM towel might show significant degradation after 50-100 washes. This long-term durability translates directly into cost savings for businesses.

Applications Across Industries: Where Towel for Bath Excels

The versatility of the **towel for bath** extends its utility across a multitude of sectors, each with specific requirements for performance, hygiene, and aesthetic appeal.

Fig 5: Neatly folded white **bath towel** and hand towels arranged in a luxurious hotel bathroom, emphasizing their role in enhancing guest experience and meeting hospitality standards.

Hospitality Sector (Hotels, Resorts, Spas):

In hotels and spas, the **towel for bath** is a key component of guest satisfaction. Requirements include:

- Luxury & Comfort: High GSM (600-800+), premium long-staple cotton for exceptional softness and plushness.

- Durability: Must withstand frequent industrial laundering without losing shape, color, or absorbency. Double-stitched hems are essential.

- Appearance: Pristine white or specific brand colors, maintaining a fresh and clean look.

- Absorbency: High absorbency ensures effective drying for guests.

Healthcare Sector (Hospitals, Clinics, Nursing Homes):

Hygiene and practicality are paramount. **Towel for bath** in healthcare settings must be:

- Hygienic: Able to withstand high-temperature washing and harsh sanitizers without degrading. Often white for visual cleanliness.

- Durable: Engineered for extreme durability against frequent, rigorous disinfection cycles.

- Absorbent: Essential for patient care and cleanliness.

- Cost-Effective: Balancing durability with procurement costs for large-scale operations.

Residential Use:

Consumers prioritize comfort, aesthetics, and personal preference.

- Variety: Wide range of materials, sizes, colors, and GSMs available.

- Softness & Absorbency: Key drivers for personal comfort.

- Aesthetics: Must complement bathroom decor.

- Ease of Care: Should be easy to wash and dry at home.

Fitness & Sports Facilities:

Quick-drying, lightweight, and durable towels are preferred. Microfiber and waffle weave cotton are common.

- Quick-Drying: Essential for frequent use and rapid turnaround.

- Lightweight & Compact: Easy to carry and store.

- Absorbent: Effective for sweat absorption.

Technical Advantages & Performance Benefits

A well-engineered **towel for bath** offers significant advantages beyond mere absorbency, translating into enhanced user experience and operational efficiency.

- Superior Absorbency: The unique loop structure of terry towels significantly increases the surface area, allowing them to wick away moisture rapidly and efficiently. For instance, a high-quality cotton **towel for bath** can absorb up to 25 times its weight in water, far exceeding many synthetic alternatives.

- Exceptional Softness and Comfort: Achieved through the use of long-staple fibers, advanced spinning techniques (e.g., ring-spun), and specific finishing processes that "fluff" the loops. This soft touch is critical for luxury applications and user satisfaction.

- Durability and Longevity: Robust weaving techniques, reinforced hems, and high-quality dyes contribute to a **towel for bath** that resists tearing, fraying, and fading, even after extensive use and industrial laundering. This reduces replacement costs and ensures a consistent quality presentation.

- Hypoallergenic and Skin-Friendly Properties: Especially for organic cotton and bamboo towels, the absence of harmful chemicals (as verified by OEKO-TEX Standard 100) makes them ideal for sensitive skin, babies, and medical environments.

- Quick-Drying Variants: Waffle weave or specific microfiber compositions optimize air circulation, allowing for much faster drying times. This is energy-efficient for commercial laundries and convenient for individual users, preventing mildew growth.

- Dimensional Stability: Through pre-shrinking processes like Sanforizing, high-quality towels minimize shrinkage and maintain their original size and shape, ensuring a consistent fit and appearance over time.

Manufacturer Comparison & Selection Criteria

Choosing the right manufacturer for your **towel for bath** needs is as crucial as selecting the towel itself. A reputable manufacturer offers not just products but also reliability, quality assurance, and tailored solutions.

Fig 6: A modern textile manufacturing facility showcasing advanced machinery and organized processes, indicative of a high-quality **bathroom linen** producer.

Key Factors for Manufacturer Selection:

- Industry Reputation & Experience: Look for manufacturers with a proven track record, extensive experience in textile production, and positive industry reviews. Companies with decades of service often have deeply ingrained quality processes.

- Certifications & Compliance: Verify certifications like OEKO-TEX Standard 100, GOTS (Global Organic Textile Standard) for organic products, and ISO 9001 for quality management systems. These indicate adherence to international quality and safety benchmarks.

- Production Capacity & Lead Time: Assess their ability to meet your volume requirements and their efficiency in delivery. For large orders, understanding their production pipeline and typical lead times is essential.

- Customization Capabilities: If branding or specific design elements are required (e.g., custom sizes, colors, weaves, embroidery), ensure the manufacturer has the expertise and equipment to fulfill these unique requirements for your **towel for bath**.

- Quality Control & Testing: Inquire about their internal QC procedures, testing protocols (e.g., for colorfastness, absorbency, shrinkage), and how they handle non-conforming products.

- Pricing Structure & Payment Terms: Obtain clear, transparent quotes. Evaluate the overall value, considering product quality, service, and delivery, not just the lowest price.

- After-Sales Support & Warranty: A reliable manufacturer stands behind its products. Inquire about their return policy, warranty against defects, and customer support channels.

- Sustainability Practices: For eco-conscious businesses, evaluate their commitment to sustainable sourcing, water/energy efficiency, and waste reduction.

Manufacturer Evaluation Checklist

| Criterion | Priority (High/Medium/Low) | Evaluation Questions |

|---|---|---|

| Quality Certifications | High | Are they OEKO-TEX, GOTS, ISO 9001 certified? |

| Production Capacity | High | Can they meet our peak demand? What is the MOQ? |

| Customization Options | High | Do they offer embroidery, custom colors, specific weaves for our **bath towel**? |

| Lead Time & Logistics | Medium | What are typical production and delivery times? Do they offer global shipping? |

| Quality Control Protocol | High | What internal tests do they conduct (GSM, absorbency, colorfastness)? |

| Customer Support | Medium | Is there a dedicated account manager? How are issues resolved? |

| Pricing & Terms | High | Are their pricing competitive for the quality offered? What are payment terms? |

| Sustainability | Medium | What environmental initiatives do they have? (e.g., water recycling, organic materials) |

Customization Solutions for Your Brand's Towel for Bath

Customization allows businesses to create unique, branded **towel for bath** products that reinforce their identity and enhance customer experience. This is particularly valuable in hospitality, corporate gifting, and specialized retail.

- Custom Colors: Matching specific brand palettes using precise dyeing techniques.

- Embroidery: Adding logos, monograms, or intricate designs for a sophisticated and personalized touch. This is popular for hotel chains and luxury spas.

- Jacquard Weaving: Weaving patterns, logos, or brand names directly into the fabric during the weaving process. This offers a more integrated, durable, and premium look than embroidery.

- Custom Sizes & GSM: Producing towels to exact specifications for unique applications or to differentiate product lines (e.g., oversized **bath towel**, specific gym towel dimensions).

- Bespoke Packaging: Tailored packaging with brand elements enhances the unboxing experience for retail or gifting purposes.

By leveraging these customization options, businesses can elevate their **bathroom linen** offerings, creating a memorable impression and strengthening brand loyalty.

Real-World Application Cases & Success Stories

The practical benefits of high-quality **towel for bath** products are best illustrated through their successful application in diverse settings.

Fig 7: A pristine array of white towels, ready for use, symbolizing the successful integration of high-quality **bathroom linen** in a client's operational setting, reflecting reliability and premium service.

Case Study 1: Luxury Hotel Chain Upgrade

A major international luxury hotel chain sought to elevate its guest experience by upgrading all **bathroom linen**. They transitioned to 700 GSM long-staple Egyptian cotton **bath towel** and matching **wash cloth** with custom jacquard woven logos. The immediate feedback from guests was overwhelmingly positive, citing "unparalleled softness" and "spa-like luxury." Despite a higher initial cost per unit, the towels demonstrated exceptional durability, resisting fading and maintaining plushness even after 250+ commercial washes over two years, significantly reducing replacement cycles and long-term operational costs compared to their previous suppliers.

Case Study 2: Eco-Conscious Boutique Spa

A high-end boutique spa, committed to sustainability, partnered with a certified OEKO-TEX and GOTS organic cotton **towel for bath** manufacturer. They specifically chose bamboo-blend towels for their natural antimicrobial properties and extraordinary softness, appealing to clients with sensitive skin. The spa reported reduced laundry detergent use due to the towels' easy-rinse nature and fast-drying capabilities, contributing to their environmental goals while providing a superior, health-conscious experience for their clientele.

Case Study 3: Large Healthcare System Standardization

A large hospital network implemented a new protocol for its **wash cloth** and **bath towel** inventory to enhance patient hygiene and operational efficiency. They opted for a robust, bleach-resistant, 450 GSM blended cotton **towel for bath** designed for extreme durability and rapid drying. The standardization across all facilities led to streamlined procurement, reduced instances of towel degradation from harsh sanitization processes, and improved turnaround times in their laundries, ultimately contributing to better infection control and resource management.

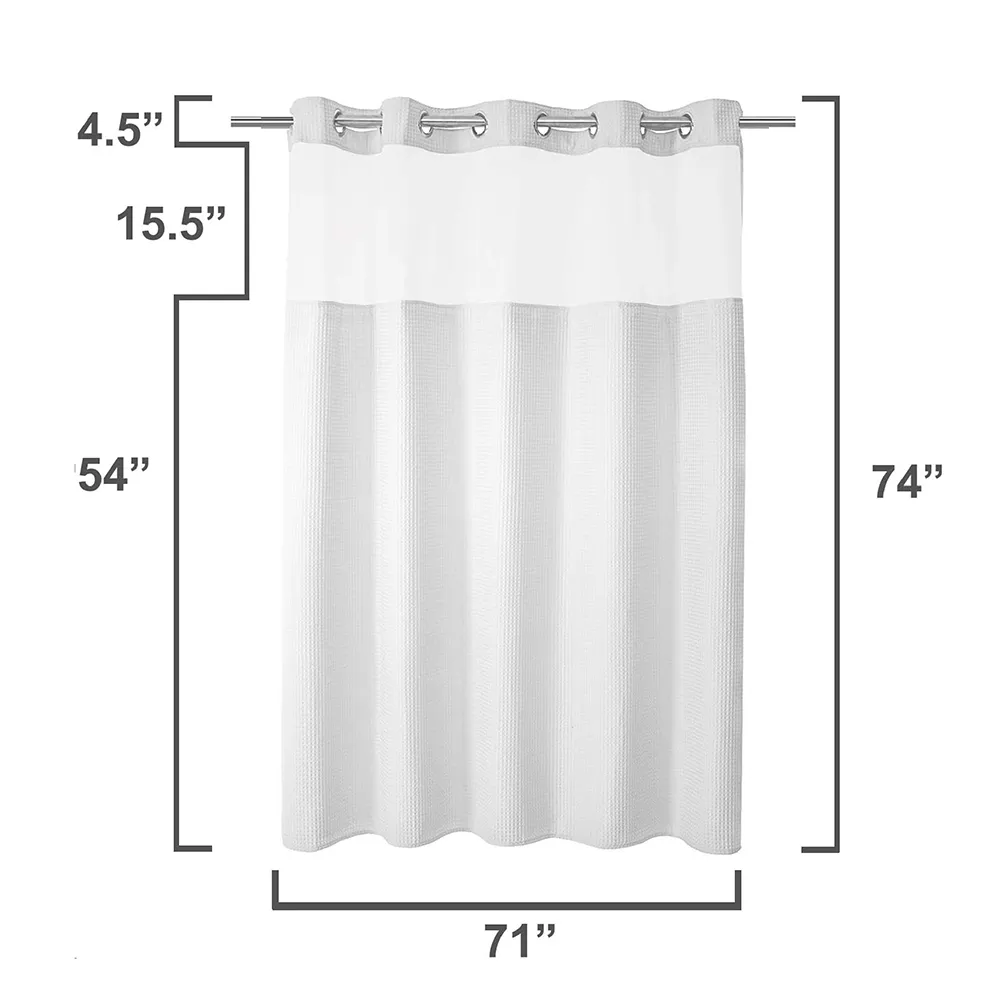

Product Highlight: Wholesale White Hotel Waterproof Waffle Shower Curtain

While our discussion extensively covers the unparalleled quality and versatility of the **towel for bath**, we at Longshow Textile are proud to extend our commitment to excellence across a full spectrum of bathroom textiles. Our featured product, the Wholesale White Hotel Waterproof Waffle Shower Curtain, exemplifies our dedication to durable, aesthetically pleasing, and highly functional solutions for the hospitality sector and beyond. Crafted with a premium waffle weave and treated for superior waterproofing, it provides both elegance and practicality, ensuring a clean, inviting, and dry bathroom environment for guests. Explore this and our other exceptional **bathroom linen** products on our website.

Trust and Reliability: Our Commitment to Excellence

At Longshow Textile, our commitment to providing high-quality **towel for bath** and **bathroom linen** is built on a foundation of transparency, unwavering quality control, and exceptional customer support. We understand that trust is earned, and we strive daily to exceed expectations.

Frequently Asked Questions (FAQ) about Towel for Bath

Q1: What does GSM stand for and why is it important for a **towel for bath**?

GSM stands for Grams per Square Meter. It is a measure of the density or weight of the fabric. A higher GSM indicates a denser, heavier, and typically more absorbent and luxurious **towel for bath**. For example, a 700 GSM towel is significantly plusher than a 400 GSM towel.

Q2: What is the difference between Egyptian and Turkish cotton for a **bath towel**?

Egyptian cotton has extra-long staple fibers, making towels incredibly soft, strong, and highly absorbent, ideal for a plush, luxurious feel. Turkish cotton has longer fibers than regular cotton but slightly shorter than Egyptian, offering a good balance of absorbency and quicker drying time, resulting in a soft, fluffy **towel for bath**.

Q3: How do OEKO-TEX Standard 100 certifications ensure product safety?

OEKO-TEX Standard 100 is an independent certification system that tests textile products at all processing stages for harmful substances. If a **towel for bath** carries this label, it means every component, from the thread to the dyes, has been tested for hundreds of chemicals and found to be harmless to human health.

Q4: What specific care instructions maximize the lifespan of a **towel for bath**?

To maximize lifespan, wash **towel for bath** in cold or warm water with a mild detergent, avoid fabric softeners (which reduce absorbency), and use non-chlorine bleach for whites. Tumble dry on low heat to prevent fiber damage. Shake towels before drying to fluff loops and reduce drying time. Do not iron terry towels as it can crush the loops.

Q5: What are the benefits of a waffle weave **towel for bath** compared to traditional terry?

Waffle weave towels have a distinctive honeycomb pattern that creates more surface area for absorption while remaining relatively thin and lightweight. This allows them to dry much faster than traditional terry towels, making them ideal for humid environments, travel, or quick turnaround laundry cycles, though they might feel less plush than high-GSM terry towels.

Q6: How does a manufacturer ensure colorfastness for colored **bathroom linen**?

Manufacturers ensure colorfastness through specific dyeing processes, like reactive dyeing, which chemically bonds the dye to the fabric fibers. They also conduct rigorous testing based on international standards such as ISO 105-C06 (Colorfastness to Washing) and ISO 105-B02 (Colorfastness to Light) to guarantee the colors will resist fading and bleeding during washing and exposure to light.

Q7: Can **towel for bath** be customized for brand promotion?

Absolutely. High-quality **towel for bath** can be customized in various ways for brand promotion, including custom sizing, specific color matching, embroidery of logos or monograms, and even intricate jacquard weaving of brand patterns directly into the fabric. These options are highly popular for hotels, spas, corporate gifts, and promotional events to create a lasting brand impression.

Delivery Schedule & Lead Time

Our standard production lead time for bulk orders of **towel for bath** ranges from 4-6 weeks, depending on the complexity of customization and order volume. Expedited options are available upon request. We work with reliable logistics partners to ensure timely and secure global delivery. Specific lead times will be confirmed upon order placement.

Quality Assurance & Warranty

We stand behind the superior quality of our **bathroom linen** products. Every **towel for bath** undergoes stringent multi-stage quality control inspections, from raw material to finished product. We offer a comprehensive warranty against manufacturing defects, ensuring that our products meet or exceed industry standards for durability, absorbency, and colorfastness. Your satisfaction is our guarantee.

Dedicated Customer Support

Our expert team is available to assist you with product selection, customization queries, order tracking, and any post-purchase support. We believe in building lasting relationships through responsive and knowledgeable customer service, ensuring a seamless experience for all your **towel for bath** and **wash cloth** needs.

Conclusion: The Art and Science of the Perfect Towel for Bath

The journey through the world of the **towel for bath** reveals it to be far more than a simple textile. It is a product of sophisticated textile engineering, material science, and meticulous quality control, designed to deliver optimal performance, comfort, and longevity. From the selection of premium long-staple cottons to advanced weaving techniques, and adherence to stringent international standards like OEKO-TEX and ISO, every stage contributes to its excellence. Whether destined for the opulent suites of a five-star hotel, the sterile environment of a hospital, or the cozy comfort of a home, the right **towel for bath** embodies a blend of luxury, functionality, and enduring quality. Understanding these nuances empowers consumers and businesses alike to make choices that align with their values for comfort, sustainability, and operational efficiency, proving that even in seemingly simple items like a **bath towel**, true craftsmanship and scientific precision elevate the everyday into an experience of sublime comfort and reliability.

References & Further Reading:

- [1] Grand View Research. (2023). "Towels Market Size, Share & Trends Analysis Report By Product (Bath Towels, Beach Towels, Kitchen Towels), By Distribution Channel, By Region, And Segment Forecasts, 2023 - 2030." Available at: https://www.grandviewresearch.com/industry-analysis/towels-market

- [2] OEKO-TEX® International. (n.d.). "OEKO-TEX® Standard 100." Available at: https://www.oeko-tex.com/en/our-standards/oeko-tex-standard-100

- [3] American Association of Textile Chemists and Colorists (AATCC). (n.d.). "Test Methods & Procedures." Available at: https://www.aatcc.org/testing/methods/

- [4] ISO. (n.d.). "ISO 105: Textiles -- Tests for colour fastness." Available at: https://www.iso.org/standard/69085.html

-

Elevating Comfort and Quality with the Right Bed LinenNewsJul.07, 2025

-

Bedding Essentials: From Percale Sheets to White Quilts, Finding Your Perfect Sleep HavenNewsJul.07, 2025

-

Choosing the Right Bedding for a Comfortable and Stylish BedroomNewsJul.07, 2025

-

Understanding the Diverse World of Towel TypesNewsMay.29, 2025

-

The Ultimate Comfort: Discover the Benefits of Polycotton SheetsNewsMay.29, 2025

-

Experience Luxury with 1800 Brushed Microfiber SheetsNewsMay.29, 2025

-

Elevate Your Sleep with Luxurious Hotel Sheets for SaleNewsMay.29, 2025