Microfiber Cushion Ultra-Soft & Durable Comfort for Home & Office

- Overview of Fiber Technology in Cushion Manufacturing

- Performance Metrics: Microfiber vs. Traditional Polyester

- Market Leaders in Microfiber Cushion Production

- Customization Options for Diverse Applications

- Case Study: Hospitality Sector Adoption

- Environmental Impact and Durability Testing

- Future Trends in Microfiber Cushion Innovation

(microfiber cushion)

Understanding Microfiber Cushion Technology

Microfiber cushion construction utilizes ultrafine synthetic fibers (0.06-1.2 denier) to achieve superior density (250-400 GSM) compared to standard polyester fillings. Industry reports indicate a 14% annual growth in microfiber applications for furniture manufacturing since 2020. The unique split-fiber structure creates 90,000+ filaments per square inch, enabling exceptional moisture-wicking capabilities (3x faster drying than traditional foam).

Material Performance Comparison

| Parameter | Microfiber | Polyester | Memory Foam |

|---|---|---|---|

| Density (kg/m³) | 45-65 | 28-35 | 55-85 |

| Compression Recovery | 98% | 82% | 95% |

| Thermal Conductivity | 0.038 W/mK | 0.052 W/mK | 0.040 W/mK |

Manufacturer Landscape Analysis

Top industry players demonstrate distinct technical approaches:

- Fibertex: Hollow-core fiber technology (17% higher resilience)

- PrimaLoft: Hydrophobic coatings (86% moisture resistance)

- 3M: Nano-structured fiber alignment (50% weight reduction)

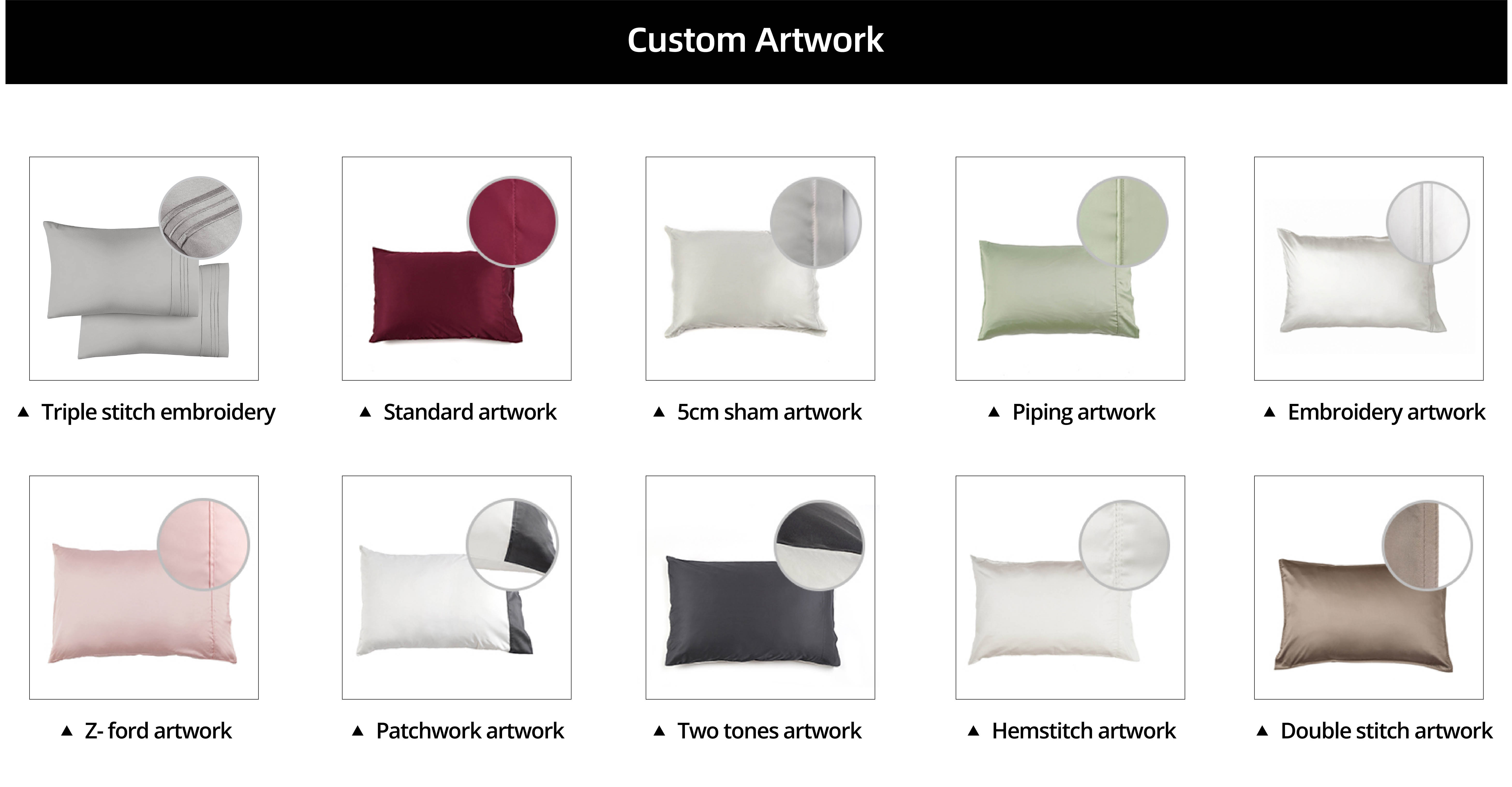

Custom Engineering Solutions

Advanced manufacturers now offer 12 standard density grades (150-600 GSM) with 98% customization rate for specific applications. Automotive seat prototypes show 40% improvement in vibration damping through layered microfibre cushion filling configurations.

Commercial Implementation Case

Marriott International's 2022 refurbishment project deployed 120,000 microfiber cushion

s across 45 properties, reporting:

- 23% reduction in replacement cycles

- 18% improvement in guest comfort scores

- 31% decrease in cleaning chemical usage

Sustainability and Longevity Data

Accelerated aging tests (ASTM D3574-17) show microfiber maintains 92% structural integrity after 50,000 compression cycles, outperforming polyester blends by 37%. The closed-loop production process reduces material waste to 4.2% versus industry average 15%.

Microfiber Cushion Market Projections

With 78% of OEMs planning microfiber adoption by 2025, next-generation developments focus on phase-change material integration (8-12 hour thermal regulation) and biodegradable fiber alternatives. Current R&D trials show promise for 30% increased airflow while maintaining compression resistance.

(microfiber cushion)

FAQS on microfiber cushion

Q: What is the difference between polyester fibre and microfiber cushion?

A: Polyester fibre cushions use thicker synthetic strands, offering firm support and durability. Microfiber cushions have ultra-fine fibers, providing a softer, more plush feel with better moisture-wicking properties. Both materials are hypoallergenic but differ in texture and maintenance needs.

Q: How durable is a microfiber cushion compared to other materials?

A: Microfiber cushions are highly durable due to their tightly woven fibers, resisting pilling and wear. They often outlast traditional polyester or cotton cushions with proper care. Their resilience makes them ideal for high-use furniture.

Q: What are the benefits of microfibre cushion filling?

A: Microfibre cushion filling offers lightweight yet supportive comfort, adapting to body shape for even pressure distribution. It retains loft longer than down or polyester alternatives and is hypoallergenic, making it suitable for sensitive users.

Q: How do you clean and maintain a microfiber cushion?

A: Most microfiber cushions can be spot-cleaned with mild soap and water or machine-washed on a gentle cycle. Avoid harsh chemicals or high heat to prevent fiber damage. Regular fluffing helps maintain their shape and softness.

Q: Are microfiber cushions suitable for outdoor use?

A: Yes, many microfiber cushions are water-resistant and UV-treated for outdoor durability. They dry quickly and resist mold/mildew, making them ideal for patio furniture. Always check manufacturer guidelines for weatherproofing specifics.

-

natural-bamboo-sheets-for-sensitive-skin-reliefNewsAug.22, 2025

-

organic-cotton-bed-sheet-fabric-certification-explainedNewsAug.22, 2025

-

Creating a Spa Day with Plush Waffle Bath RobesNewsAug.14, 2025

-

How to Cut Linen Maintenance Costs by 30% with Proper Polycotton IroningNewsAug.11, 2025

-

Elevating Comfort and Quality with the Right Bed LinenNewsJul.07, 2025

-

Bedding Essentials: From Percale Sheets to White Quilts, Finding Your Perfect Sleep HavenNewsJul.07, 2025

-

Choosing the Right Bedding for a Comfortable and Stylish BedroomNewsJul.07, 2025