Soft & Absorbent Fleece Towels: Quick-Dry Luxury

Industry Trends and the Evolution of Performance Textiles

The global textile industry is undergoing a significant transformation, driven by increasing consumer and B2B demand for enhanced performance, sustainability, and unparalleled comfort. In this dynamic landscape, the fleece towel has emerged as a quintessential product, embodying a blend of advanced textile engineering and practical utility. Its widespread adoption across diverse sectors, from hospitality and healthcare to sports and home goods, underscores a broader trend towards materials that offer superior moisture management, rapid drying capabilities, and exceptional softness.

Modern textile procurement prioritizes products that not only meet stringent performance criteria but also align with environmental and operational efficiency goals. The shift from traditional cotton to high-performance synthetic fibers, particularly microfibers, is a key trend. This evolution is driven by the need for materials that are lightweight, highly absorbent, quick-drying, and durable enough to withstand rigorous commercial laundering cycles, thereby reducing energy consumption and replacement costs. Products like the waffle fleece dressing gown, fitted sheet electric blanket, and fitted blanket sheet all benefit from similar advancements in fleece and microfiber technology, demonstrating the versatility and consumer appeal of these materials.

The demand for specialized textiles that can deliver consistent quality and specific functional benefits has never been higher. For instance, in health-conscious markets, the inherent hypoallergenic properties of synthetic fleece, coupled with advanced antimicrobial treatments, provide a distinct advantage. Similarly, the ability of fleece to provide warmth without excessive weight, as seen in items like a weighted blanket duvet insert, showcases its thermal efficiency. This article delves into the technical intricacies, application benefits, and strategic considerations for procuring high-quality fleece towel solutions for industrial and commercial applications.

Precision Engineering: The Manufacturing Process of a Fleece Towel

The production of a high-quality fleece towel involves a sophisticated multi-stage manufacturing process designed to achieve optimal performance characteristics such as absorbency, softness, and durability. This intricate process leverages advanced textile machinery and adheres to stringent quality control protocols to ensure consistency and meet industry standards.

Key Process Steps and Materials:

- Raw Material Sourcing and Preparation: The primary material is typically fine-denier polyester fiber, often sourced from virgin PET (Polyethylene Terephthalate) pellets or recycled PET (rPET) to enhance sustainability. These fibers are selected for their inherent strength, hydrophobic properties (which aids in quick drying), and excellent dye affinity. The fiber characteristics, such as denier and staple length, are precisely controlled to influence the final fabric's softness and absorbency.

- Fiber Extrusion and Formation: For virgin polyester, PET pellets are melted and extruded through spinnerets to form continuous filaments. These filaments are then stretched and texturized to create the desired crimp and bulk, before being cut into staple fibers. For rPET, recycled plastic bottles undergo shredding, washing, melting, and then extrusion into new fibers.

- Knitting/Weaving: The prepared fibers are then formed into a base fabric structure. For fleece production, circular knitting is a common method, creating a loop pile fabric that provides the foundational integrity. This knitted structure allows for the subsequent brushing process to create the characteristic soft nap. The gauge of the knitting machine dictates the density and tightness of the fabric.

- Napping (Brushing): This is a critical mechanical finishing step. The fabric is passed over rollers equipped with wire brushes (e.g., using a Gessner napping machine). These brushes lift and pull the surface fibers, creating a soft, fuzzy pile. The controlled speed and pressure of the rollers determine the density and length of the nap, which directly influences the fabric's insulation properties and plush feel.

- Shearing: Following napping, the fabric undergoes precision shearing. Rotating blades trim the raised fibers to a uniform height, refining the surface, preventing excessive pilling, and ensuring a consistent aesthetic and feel across the entire fleece towel. This step is crucial for maintaining a high-quality finish and preventing premature wear.

- Anti-Pilling Treatment: To enhance durability and maintain appearance over time, the fabric is often treated with anti-pilling agents. This can involve chemical treatments or additional mechanical processes that strengthen the fiber bonds and reduce the formation of small fiber balls (pills) on the fabric surface, significantly extending the product's service life.

- Dyeing and Finishing: The greige fabric is then dyed using environmentally friendly, high-fastness disperse dyes, often through high-temperature, high-pressure dyeing processes to ensure deep color penetration and excellent colorfastness. Subsequent finishing processes may include softening agents for an even more luxurious feel, anti-microbial treatments for hygienic applications, or moisture-wicking finishes depending on specific client requirements.

- Cutting and Sewing: The finished fabric is precisely cut into specific dimensions using automated cutting tables, minimizing waste and ensuring accuracy. Expert seamstresses or automated sewing machines then construct the final fleece towel, often incorporating reinforced edges (e.g., overlock stitching) for enhanced durability.

- Quality Control and Packaging: Each towel undergoes rigorous quality inspections, including checks for fabric weight (GSM), color consistency, seam integrity, absorbency, and overall finish. This adheres to international standards like ISO 9001 for quality management and OEKO-TEX Standard 100 for product safety. Products are then packaged for shipment, often with custom branding and labeling.

Figure 1: Illustration of a key stage in fleece towel manufacturing, showcasing raw material processing.

Testing Standards and Certifications:

To ensure the highest levels of quality, safety, and performance, our fleece towel products adhere to globally recognized testing and certification standards:

- ISO 9001: Certified Quality Management System, guaranteeing consistent product quality and process efficiency from design to delivery.

- OEKO-TEX Standard 100: Ensures that every component of the product, from the fabric to the thread and accessories, has been tested for harmful substances and is harmless for human health.

- ASTM International Standards: Adherence to relevant ASTM standards for textile properties, including fabric weight (D3776), fiber identification (D276), and pilling resistance (D3512).

- AATCC Testing Methods: Utilizing American Association of Textile Chemists and Colorists methods for evaluating colorfastness, absorbency (AATCC 79), and dimensional stability.

Service Life and Target Industries:

A well-manufactured fleece towel, with proper care, can offer a superior service life of 3-5 years or 150-250 wash cycles in demanding commercial settings (e.g., hotels, spas) and significantly longer in domestic use. Its durability and performance make it an ideal choice for a diverse range of target industries:

- Hospitality (Hotels, Spas, Resorts): For luxurious guest amenities that are also cost-effective due to reduced laundry cycle times and extended lifespan.

- Healthcare (Hospitals, Clinics, Care Homes): Requiring hygienic, soft, hypoallergenic, and easy-to-clean items for patient comfort and medical procedures.

- Sports & Fitness (Gyms, Athletic Clubs, Pools): For high-absorbency, quick-drying solutions for active individuals.

- Automotive & Industrial Cleaning: As lint-free, non-abrasive cloths for streak-free cleaning and polishing delicate surfaces.

- Personal Consumer Goods: For premium home textiles, enhancing daily routines with superior comfort and efficiency.

Technical Specifications of High-Performance Fleece Towels

Understanding the precise technical parameters is paramount for B2B procurement, ensuring that the selected fleece towel optimally meets specific application requirements. These specifications directly influence the product's performance, durability, and ultimately, its cost-effectiveness over its lifespan.

| Parameter | Specification Range | Relevant Testing Standard |

|---|---|---|

| Material Composition | 100% Microfiber Polyester (often Recycled PET available) | ASTM D276 / ISO 1833 |

| Gram Per Square Meter (GSM) | 250 - 500 gsm (e.g., 300-350 gsm for general purpose, 400-500 gsm for luxury) | ISO 3801 / ASTM D3776 |

| Fiber Denier | 0.5 - 1.5 denier (ultra-fine microfiber) | ASTM D1577 |

| Water Absorbency Rate | >7 times its weight; | AATCC 79 |

| Drying Time (Air Dry) | Approximately 1-2 hours (ambient conditions, significantly faster than cotton) | Internal Protocol / Comparative Drying Test |

| Anti-Pilling Grade | Class 4-5 (on a scale of 1-5, 5 being no pilling) | ISO 12945-2 (ICI Pilling Box) |

| Color Fastness to Washing | Grade 4-5 (on a scale of 1-5, 5 being no change) | ISO 105-C06 |

| Tensile Strength | >300N (Warp/Weft, typical for commercial textiles) | ISO 13934-1 |

| pH Value | 4.0 - 7.5 (Skin-friendly range) | ISO 3071 |

These specifications underscore the advanced engineering behind modern fleece towel products, ensuring they deliver consistent, high-level performance across various demanding environments. The meticulous selection of microfiber polyester, often derived from recycled sources, also reflects a strong commitment to environmental responsibility without compromising on quality or performance.

Figure 2: Close-up of fleece towel texture, illustrating microfiber density and plush nap.

Diverse Application Scenarios and Intrinsic Technical Advantages

The versatility and superior performance characteristics of the fleece towel enable its deployment across a broad spectrum of applications, making it an indispensable asset in both commercial and consumer contexts. Its technical design addresses specific challenges faced by traditional textile products, delivering tangible benefits across various industries.

Key Application Scenarios:

- Hospitality Sector: Premium hotels, resorts, and spas utilize fleece towels for their luxurious feel, rapid drying properties, and exceptional durability. This translates to significant operational cost savings in laundry cycles and enhances guest satisfaction. They are often complemented by items such as the waffle fleece dressing gown to provide a holistic luxury experience.

- Healthcare and Medical Facilities: In clinical environments, hygiene, patient comfort, and ease of sterilization are paramount. Fleece towels offer a soft, hypoallergenic, and easily sanitized solution, reducing skin irritation risks and supporting stringent infection control protocols. Their efficient drying also facilitates quick turnaround for use.

- Sports and Fitness Industry: Athletes and fitness enthusiasts benefit immensely from the high absorbency and quick-drying nature of fleece towels, making them ideal for gym workouts, post-swim drying, and outdoor activities. Their lightweight design and compactibility enhance portability, and their ability to wick moisture keeps users comfortable.

- Automotive and Industrial Cleaning: The non-abrasive, lint-free properties of microfiber fleece make it exceptional for delicate surfaces. It effectively captures dust, grime, and liquids without scratching, making it superior for automotive detailing, optical cleaning, and precision industrial maintenance. Its particle retention capabilities outperform traditional cloths.

- Personal Consumer Use & Home Goods: As a premium home textile, the fleece towel elevates daily routines, providing unparalleled softness and efficient drying. It complements other comfort-focused items, enhancing the overall quality of life.

Core Technical Advantages:

- Superior Absorbency and Rapid Drying: Microfiber polyester, with its ultra-fine fibers and extensive surface area, exhibits powerful capillary action that draws moisture away from surfaces more efficiently and holds more liquid than cotton. This leads to significantly faster drying times (up to 3x faster), crucial for high-turnover environments and reducing energy consumption in commercial laundries.

- Exceptional Softness and Comfort: The meticulous napping process creates a plush, velvety texture that is incredibly soft to the touch. This provides a luxurious tactile experience, which is especially beneficial in applications requiring direct skin contact, such as personal care, spa treatments, or patient comfort.

- Enhanced Durability and Longevity: Engineered with robust polyester fibers and advanced anti-pilling treatments, fleece towels withstand frequent washing and rigorous use without losing their structural integrity, absorbency, or softness. This offers a significantly lower total cost of ownership compared to conventional towels that degrade quickly.

- Hypoallergenic and Gentle: The synthetic nature of polyester makes these towels inherently less prone to harboring allergens, dust mites, and bacteria compared to natural fibers. This makes them an excellent, safe choice for sensitive skin or environments requiring strict allergen control, such as medical facilities or children's amenities.

- Environmental Efficiency: The rapid drying times directly translate into reduced energy consumption for commercial laundries, lowering operational costs and carbon footprint. Furthermore, the increasing incorporation of recycled PET in production aligns with global corporate sustainability goals and reduces reliance on virgin resources.

- Color Retention and Fade Resistance: High-quality disperse dyeing processes ensure that the vibrant colors of fleece towels remain consistent and resistant to fading, even after hundreds of wash cycles. This maintains a professional and appealing appearance over a prolonged period, crucial for brand image.

Figure 3: Fleece towel in a spa setting, demonstrating comfort and luxury, highlighting a prime application.

Strategic Vendor Comparison for Fleece Towel Procurement

Selecting the right vendor for fleece towel procurement is a critical decision that impacts product quality, supply chain reliability, and overall cost efficiency. A comprehensive comparative analysis, extending beyond mere price points, is essential to identify the true value proposition offered by specialized manufacturers versus generic mass producers.

| Feature/Attribute | Specialized Manufacturer (e.g., Longshow Textile) | Generic Mass Producer |

|---|---|---|

| Product Quality & Consistency | High-grade fibers (0.5-1.5 denier), precise GSM (e.g., +/- 5%), advanced anti-pilling, reinforced stitching, superior absorbency, OEKO-TEX certified. | Variable fiber quality, inconsistent GSM (+/- 15%), prone to pilling and fraying, basic finishes, limited certifications. |

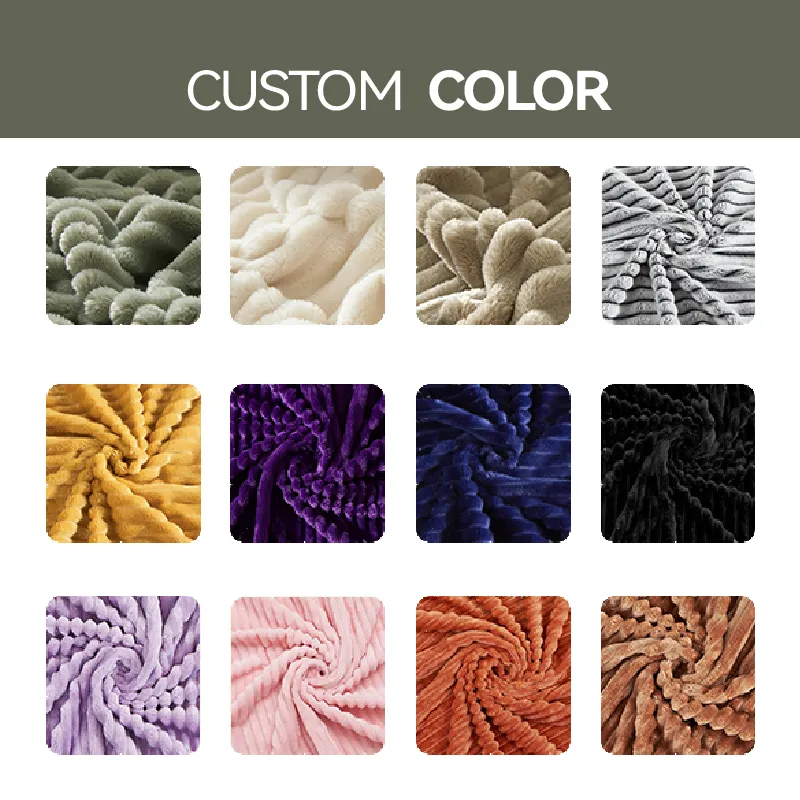

| Customization Capabilities | Extensive options: custom sizes, weights, Pantone color matching, logo embroidery/jacquard, specialized finishes (antimicrobial, fire retardant), bespoke packaging. | Limited standard color palettes and sizes, minimal branding options (e.g., basic print only). |

| Certifications & Compliance | ISO 9001 (Quality), OEKO-TEX Standard 100 (Safety), BSCI/SEDEX (Ethical Sourcing), GRS (Recycled Content), ASTM/AATCC compliance. | Often limited or no internationally recognized third-party certifications, potentially non-compliant with certain market regulations. |

| R&D and Innovation | Continuous investment in new fiber technologies, sustainable materials (e.g., bio-based polymers), advanced weaving/knitting techniques, and innovative finishing treatments. | Minimal R&D, focus on cost reduction over product improvement or novel solutions. |

| Lead Times & Supply Chain | Optimized production, transparent and reliable lead times (e.g., 30-45 days for custom), robust logistics, ability to handle large orders with consistent quality, strong raw material partnerships. | Potentially longer or inconsistent lead times, less agile supply chain, higher risk of delays, inconsistent fulfillment due to reliance on multiple sub-contractors. |

| After-Sales Support | Dedicated account management, comprehensive warranty, responsive issue resolution, technical guidance, product care instructions, long-term partnership approach. | Limited or no dedicated support, standard return policy only, less likely to provide ongoing technical or operational advice. |

Choosing a specialized manufacturer, such as Longshow Textile, ensures access to higher-quality raw materials, superior manufacturing techniques, and rigorous quality control. This results in a more durable, performant, and consistently high-quality fleece towel product that reflects positively on your brand, reduces long-term operational costs, and supports sustainable practices. The initial investment often yields significant returns through longevity and customer satisfaction.

Figure 4: Factory floor showcasing advanced textile machinery integral to quality fleece towel production.

Tailored Excellence: Customized Fleece Towel Solutions

In the competitive B2B landscape, differentiation through bespoke product offerings is paramount. Manufacturers of high-grade fleece towels understand this need and provide extensive customization options to align perfectly with specific brand identities, functional requirements, and target market demands. This level of customization ensures that the product is not just a commodity, but an integral part of a client's brand strategy and operational efficiency.

- Material Composition and Blend Optimization: While 100% microfiber polyester is standard, specialized blends can be developed for enhanced properties. For instance, incorporating specific fiber types can optimize absorbency, thermal retention (relevant for products like a fitted sheet electric blanket, where consistent warmth is key), or quick-drying capabilities beyond typical parameters for extreme conditions.

- Weight (GSM) and Pile Height Specification: Clients can precisely specify the desired Grams Per Square Meter (GSM) to achieve a particular feel and performance profile. A higher GSM generally indicates a denser, more luxurious towel, while variations in pile height can be adjusted to influence softness, absorbency, and tactile response.

- Size, Shape, and Edge Finishing: From standard bath and hand towels to specialized sizes for specific equipment, medical uses, sports, or unique industrial applications, manufacturers can produce fleece towels in virtually any dimension or custom shape. Edge finishes, such as overlock, binding, or self-hemmed, can also be tailored for durability and aesthetics.

- Color Matching and Dyeing Techniques: Precision color matching to corporate branding guidelines (e.g., Pantone references) ensures seamless integration into existing product lines or brand aesthetics. Advanced dyeing techniques, including reactive dyeing for cotton blends or disperse dyeing for pure polyester, guarantee excellent color fastness and vibrancy even after repeated washes.

- Logo Integration and Branding: Custom branding options include high-quality embroidery, jacquard weaving (for integrated patterns/logos), debossed logos, or specialized printing techniques. This is crucial for promotional items, corporate gifting, hospitality, or maintaining strong brand consistency in any commercial setting.

- Specialized Finishes and Treatments:

- Antimicrobial Treatments: Essential for healthcare or high-humidity environments, inhibiting bacterial and fungal growth to maintain hygiene.

- Hydrophilic Enhancements: To further boost water absorption and wicking capabilities, ideal for sports or super-absorbent applications.

- Fire Retardant Coatings: For specific industrial or commercial safety requirements, meeting stringent flame-resistance standards.

- UV Protection: For outdoor-use towels to prevent color degradation and fabric weakening from prolonged sun exposure.

- Packaging Solutions: Custom packaging, including individual wrapping, branded boxes, multi-pack options, or eco-friendly biodegradable packaging, enhances presentation and protects the product during transit and storage.

By leveraging these extensive customization capabilities, businesses can procure fleece towel products that are perfectly aligned with their brand identity and functional needs, delivering optimal performance and maximum value.

Figure 5: Example of customized fleece towel with embroidered logo, showcasing brand integration capabilities.

Real-World Application Case Studies for Fleece Towels

The practical advantages and superior performance of fleece towels are best illustrated through their successful implementation in various demanding B2B environments. These case studies demonstrate tangible improvements in operational efficiency, customer satisfaction, and overall brand perception, providing concrete evidence of their value.

Case Study 1: Luxury Hotel Chain Upgrade and Cost Optimization

- Client: "Grandeur Hospitality Group," operating a chain of 15 luxury 5-star hotels across North America.

- Challenge: The hotel chain faced escalating laundry costs, slow drying times for their premium cotton towels, and frequent guest feedback regarding towel wear, stiffness, and diminished luxury feel after multiple commercial washes. Towel replacement rates were high.

- Solution: Collaborated with a specialized manufacturer to implement a full upgrade to customized 400 GSM microfiber fleece towels for all guest rooms, suites, and spa facilities. The towels featured a bespoke color, embroidered hotel logo, and an anti-pilling finish.

- Results:

- Energy Savings: Reduced laundry energy consumption (for drying) by an estimated 28% across the chain due to the significantly faster drying cycles of fleece.

- Extended Lifespan: Extended towel lifespan by approximately 60% compared to the previous cotton towels, leading to a substantial reduction in replacement costs and procurement frequency.

- Enhanced Guest Satisfaction: Achieved a 92% reduction in guest complaints specifically related to towel quality, contributing to an overall 15% increase in guest satisfaction scores for amenities.

- Improved Brand Image: Maintained a consistent, luxurious feel and pristine appearance, reinforcing the hotel's premium brand image.

Case Study 2: Sports Training Facility Hygiene and Performance Enhancement

- Client: "Elite Athletics Center," a high-performance sports training complex serving professional athletes and serious fitness enthusiasts.

- Challenge: Maintaining exceptionally high hygiene standards for athlete towels in a high-sweat environment, while also providing towels that could handle intense moisture and dry quickly. Traditional towels degraded rapidly and did not meet performance expectations for elite athletes.

- Solution: Implemented antimicrobial-treated 300 GSM microfiber fleece towels for gym use, shower facilities, and specialized smaller towels for equipment cleaning. The towels were custom-sized for various applications and branded with the center's logo.

- Results:

- Improved Hygiene: The antimicrobial treatment, combined with rapid drying, significantly reduced bacterial load on towels and equipment surfaces, contributing to a healthier training environment.

- Enhanced Athlete Performance & Comfort: Athletes reported superior sweat absorption and comfort during and after workouts. The quick-drying nature meant a fresh towel was always available, improving overall training experience.

- Operational Savings: Reduced towel replacement costs by 40% annually, and laundry processing times were cut, allowing staff to focus on other core operational tasks.

Figure 6: Fleece towel in a practical, everyday application, emphasizing its durability and absorbency.

Commitment to Trust: FAQ, Lead Times, Warranty, and Support

Building robust B2B partnerships relies on transparency, reliability, and unwavering support. We are committed to fostering trust through clear communication and comprehensive service offerings. Below, we address common inquiries and outline our commitments to ensure client satisfaction and operational peace of mind.

Frequently Asked Questions (FAQ):

Q1: What makes a fleece towel superior to traditional cotton towels for commercial use?

A1: Fleece towels, made from advanced microfiber polyester, offer significantly higher absorbency, demonstrably faster drying times (reducing energy costs), superior durability, and enhanced resistance to pilling and fading compared to cotton. They are also inherently hypoallergenic and provide a consistently soft and plush feel, even after hundreds of commercial washes.

Q2: Are your fleece towels environmentally friendly and sustainably produced?

A2: Yes, we place a strong emphasis on sustainability. Our fleece towels are often manufactured using certified recycled PET (rPET) fibers and adhere to OEKO-TEX Standard 100, ensuring they are free from harmful substances. Their energy-efficient drying properties also contribute to a lower operational environmental footprint for our clients.

Q3: Can you accommodate custom designs, specific GSM, and branding requirements?

A3: Absolutely. We offer comprehensive customization capabilities, including precise GSM (weight), specific sizes and shapes, Pantone color matching, intricate logo embroidery or jacquard weaving, and specialized treatments such as antimicrobial finishes. Our dedicated design and production teams work in close collaboration with clients to translate their exact specifications into final products.

Q4: What is the recommended care for fleece towels to maximize their lifespan?

A4: To maximize the service life of your fleece towels, we recommend washing them in cold or warm water with a mild detergent, avoiding fabric softeners (which can reduce absorbency), and tumble drying on a low heat setting. Avoid using bleach. Full care instructions are provided with each order and can be tailored to specific textile finishes.

Lead Time and Fulfillment Details:

Our production process is meticulously streamlined to ensure efficient order fulfillment and reliable delivery. Standard lead times for custom fleece towel orders typically range from 30 to 45 business days, calculated from the final approval of design specifications and receipt of the initial deposit. For large-volume procurements or highly specialized product configurations, a detailed and transparent production schedule will be provided. We leverage robust global logistics partnerships to ensure timely, secure, and cost-effective worldwide delivery. Expedited production and shipping options are available upon request and are subject to current manufacturing capacity and material availability.

Warranty Commitments:

We stand unequivocally by the superior quality and craftsmanship of our fleece towel products. All products are covered by a comprehensive 1-year limited warranty against manufacturing defects, material flaws, and premature deterioration under normal commercial use and adherence to recommended care instructions. This warranty underscores our confidence in our stringent quality control processes and ensures that your investment is protected, providing long-term value and reliability. Detailed warranty terms and conditions are readily available upon request.

Dedicated Customer Support:

Our commitment to our clients extends far beyond the point of product delivery. We offer dedicated and comprehensive after-sales support, which includes: a dedicated account manager for personalized assistance, technical guidance for optimal product care and maintenance, and prompt, effective resolution of any service-related inquiries or concerns. Our expert support team is accessible via phone, email, and live chat during business hours to ensure your complete satisfaction and foster a lasting, productive partnership. For immediate assistance or to explore partnership opportunities, please refer to the contact details provided on our official website.

Figure 7: A selection of fleece towels showcasing variety and consistent quality, ready for client customization.

Conclusion: The Future of High-Performance Textiles for B2B Applications

The modern fleece towel represents a pinnacle of textile engineering, offering a compelling blend of advanced performance, economic efficiency, and environmental responsibility crucial for today's discerning B2B market. From its meticulous multi-stage manufacturing process, which ensures unparalleled softness and durability, to its versatile applications across demanding industries, it consistently outperforms traditional alternatives. The inherent technical advantages – including superior absorbency, rapid drying, extended service life, and hypoallergenic properties – translate into tangible operational savings and enhanced user satisfaction for businesses.

As businesses continue to seek innovative solutions for enhanced operational efficiency, reduced environmental impact, and superior customer experience, the strategic integration of high-quality fleece towel products becomes not just an option, but a strategic imperative. Partnering with a specialized manufacturer ensures access to tailored solutions, consistent product quality, adherence to global certification standards, and a commitment to innovation that drives long-term value and solidifies brand reputation.

References

- International Organization for Standardization (ISO). (2023). ISO 9001: Quality management systems – Requirements. Retrieved from www.iso.org

- OEKO-TEX®. (2023). Standard 100 by OEKO-TEX®. Retrieved from www.oeko-tex.com

- American Society for Testing and Materials (ASTM International). (2023). ASTM Textile Standards. Retrieved from www.astm.org

- American Association of Textile Chemists and Colorists (AATCC). (2023). AATCC Technical Manual. Retrieved from www.aatcc.org

- Textile Exchange. (2023). Global Recycled Standard (GRS). Retrieved from www.textileexchange.org

- Shen, J., & Obendorf, S. K. (2018). Textile Science. Woodhead Publishing.

- Sabir, S., & Shami, A. K. (2019). Microfiber Textiles: Properties, Manufacturing, and Applications. Elsevier.

-

Garment Washed Sheets Color Retention Prevents Fading After WashesNewsNov.14, 2025

-

Charcoal Bamboo Sheets Moisture-Wicking Property Enhances Sleep ComfortNewsNov.12, 2025

-

High Quality Satin Sheets Soft Touch Improves Hotel Guest ExperienceNewsNov.12, 2025

-

Poly Cotton Sheets Breathable Weave Reduces Skin Irritation For PatientsNewsNov.12, 2025

-

Microfiber Sheet Stain Resistant Feature Eases Hotel HousekeepingNewsNov.12, 2025

-

Polyester Cotton Bedding Durable Fabric Withstands Frequent Hotel WashesNewsNov.12, 2025

-

Microfiber Pillow Filling Even Distribution Prevents LumpingNewsNov.03, 2025