Soft Cotton Bed Sheets | King Size Bedding & Sage Green

Elevating Guest Experience: The Strategic Role of Premium Bedding in Hospitality

In the highly competitive global hospitality sector, the guest experience is paramount, with bedding playing a pivotal role in comfort, perception, and repeat business. The demand for superior quality cotton bed sheets continues to surge, driven by discerning travelers who prioritize sleep quality and luxurious tactile sensations. Industry trends indicate a significant shift towards sustainable, hypoallergenic, and exceptionally durable textile solutions that withstand rigorous commercial laundering cycles while maintaining their pristine appearance and comfort. For procurement professionals, understanding these dynamics means investing in materials that not only meet aesthetic and comfort standards but also deliver long-term value through extended service life and reduced replacement costs. This strategic approach ensures operational efficiency while simultaneously enhancing brand reputation through consistent delivery of a premium sleep environment. The market also shows increasing interest in versatile color palettes, with shades like sage green bedding gaining popularity for their calming appeal, alongside timeless options like white quilt designs, which convey cleanliness and classic elegance. Furthermore, the selection often extends to seasonal adaptations, where a lightweight summer quilt might be preferred for warmer climates or specific guest preferences, emphasizing the need for a diverse inventory to cater to varied needs.

Beyond aesthetics, the intrinsic properties of premium cotton, such as its natural breathability and moisture-wicking capabilities, are critical for ensuring guest comfort across diverse climates and personal preferences. High-quality long-staple cotton, exemplified by Egyptian or Pima varieties, offers unparalleled softness, strength, and a luxurious drape that synthetic alternatives simply cannot replicate. The inherent durability of well-constructed cotton fibers means these sheets resist pilling, tearing, and fading, even after hundreds of washes, making them an economically sound choice for high-volume environments like hotels and resorts. This longevity directly translates to a lower total cost of ownership (TCO) compared to cheaper, less durable alternatives that require frequent replacement. Moreover, the tactile experience of sleeping on crisp, smooth cotton is a significant differentiator for hotels aiming for a five-star rating or a boutique luxury experience. The selection of appropriately sized king bedding or king size sheet sets is also crucial, ensuring a perfect fit and a seamless, inviting presentation in guest rooms. This detailed attention to material quality and sizing underscores the commitment to guest satisfaction and operational excellence that defines leading hospitality establishments. The underlying technical specifications, from thread count to weave type, are fundamental in determining these performance attributes, requiring procurement specialists to possess a deep understanding of textile engineering principles.

The Art and Science: Manufacturing Process of Cotton Bed Sheets

The production of high-quality cotton bed sheets is a sophisticated multi-stage process, beginning with the meticulous selection of raw cotton fibers. The journey starts with ginning, separating the fibers from seeds and debris, followed by carding and combing, which align and clean the fibers, removing shorter staples to ensure a smooth, uniform yarn. The spinning process transforms these prepared fibers into yarn, with techniques like ring-spinning yielding finer, stronger, and smoother yarns ideal for luxury bedding due to their tighter twist and less protruding fibers. Once spun, the yarn undergoes weaving, where warp (longitudinal) and weft (transverse) threads interlace to form the fabric structure. Common weaves for bedding include percale, known for its crisp, matte finish and durability, and sateen, which offers a silky smooth feel and subtle sheen due to more warp threads on the surface. Understanding these weave patterns is crucial for matching textile properties to specific comfort and aesthetic requirements in hospitality settings. The selection of materials extends beyond cotton, occasionally integrating blends or specific finishes to enhance properties, but pure long-staple cotton remains the benchmark for premium feel and durability, making it an ideal choice for durable king bedding in high-traffic environments.

Post-weaving, the fabric undergoes an extensive finishing process that significantly impacts its performance and longevity. Mercerization, for instance, is a critical step where cotton is treated with a caustic solution under tension, enhancing its strength, luster, dye uptake, and dimensional stability, thereby extending the service life of the sheets. Bleaching follows to achieve a pure white base, essential for maintaining the pristine look of white quilt sets and other white linens. Dyeing, if applicable, precisely controls color consistency, vital for maintaining brand standards, especially for specific hues like sage green bedding. Subsequent treatments like sanforization prevent excessive shrinkage, ensuring the sheets retain their size and fit after repeated laundering. Calendering imparts a smooth, pressed finish. Throughout these stages, stringent quality control measures are implemented. Products are rigorously tested against international standards such as OEKO-TEX Standard 100 for harmful substances, GOTS (Global Organic Textile Standard) for organic content, and various ISO standards for quality management and environmental performance. These certifications assure hoteliers of product safety, environmental responsibility, and consistent quality, crucial for maintaining guest trust and brand integrity. The typical service life of high-quality hotel-grade cotton bed sheets can range from 3 to 5 years under proper commercial laundry protocols, demonstrating superior durability compared to consumer-grade alternatives, making them a wise investment for hospitality and healthcare sectors.

Technical Specifications and Performance Metrics for Hospitality Bedding

For B2B procurement in the hospitality sector, understanding the technical specifications of cotton bed sheets is paramount for making informed purchasing decisions that balance comfort, durability, and cost-effectiveness. Key parameters include thread count (TC), weave type, fiber staple length, and finishing treatments. Thread count, defined as the number of threads per square inch, impacts fabric softness and durability, with higher counts (e.g., 300-600 TC for hotels) generally indicating a finer, denser fabric. However, excessively high thread counts can sometimes indicate multi-ply yarns or inferior cotton, so it's critical to consider other factors. Weave types, such as percale, sateen, and twill, each offer distinct tactile properties and visual characteristics. Percale provides a crisp, breathable feel, ideal for a summer quilt ensemble, while sateen offers a smooth, luxurious drape often preferred for premium king bedding. The staple length of the cotton fiber directly correlates with quality; longer staples like those found in Egyptian or Pima cotton produce stronger, smoother yarns, leading to more durable and softer sheets. Critical finishing treatments like mercerization enhance fabric strength and dye absorption, while sanforization minimizes shrinkage, ensuring that king size sheet sets maintain their precise dimensions after repeated industrial laundering cycles. These technical details directly influence the sheets' resistance to pilling, tearing, and fading, thus extending their service life and ensuring a consistent guest experience.

Performance metrics are objectively measured through various industry tests. Fabric weight, often expressed in grams per square meter (GSM), indicates density and durability. Tear strength and tensile strength tests measure the fabric's resistance to ripping and breaking under stress, crucial for high-traffic hotel environments. Colorfastness to washing and light ensures that hues like those found in sage green bedding remain vibrant over time. Pilling resistance tests evaluate the fabric's tendency to form small fiber balls on the surface, which can detract from appearance and comfort. Shrinkage control is vital, with industrial-grade sheets designed to maintain dimensional stability within a narrow tolerance, typically less than 3%, after multiple washes. For instance, a high-quality 400 TC sateen cotton bed sheet might exhibit a tensile strength exceeding 300N (warp) and 250N (weft) (ASTM D5034), with less than 2% shrinkage (AATCC 135). Furthermore, compliance with specific flammability standards (e.g., NFPA 701 for certain applications) and hypoallergenic certifications are increasingly important for health and safety. These rigorous testing protocols and adherence to standards like ISO 9001 for quality management systems differentiate manufacturers who are committed to delivering reliable, high-performance textile solutions for the demanding requirements of hotels, resorts, cruise lines, and healthcare facilities where durability and guest satisfaction are paramount.

Key Specifications Comparison: Premium Cotton Bed Sheets

| Feature | Standard Hotel Grade (e.g., Longshow Textile) | Typical Luxury Hotel Grade | Economic Grade (for reference) |

|---|---|---|---|

| Material | 100% Long-Staple Cotton | 100% Extra-Long Staple Cotton (e.g., Egyptian, Pima) | Short-Staple Cotton or Blends |

| Thread Count (TC) | 200-300 TC (Percale/Sateen) | 400-600 TC (Sateen/Percale) | 150-200 TC |

| Weave | Percale or Sateen | Sateen, Dobby, Jacquard | Plain Weave |

| Shrinkage (Max after wash) | < 3% (Commercial Wash) | < 2% (Commercial Wash) | 5-10% or more |

| Tensile Strength (Warp/Weft) | 250N/200N (min.) | 300N/250N (min.) | < 150N |

| Certifications | OEKO-TEX Standard 100, ISO 9001 | OEKO-TEX, GOTS, ISO, Specific Hotel Brand Specs | Limited or None |

| Service Life (Estimated) | 3-4 Years (Consistent use) | 4-5+ Years (Consistent use) | 1-2 Years |

Strategic Procurement: Supplier Comparison and Customization Solutions

Selecting the right supplier for wholesale cotton bed sheets is a critical decision for any hospitality business, impacting not only initial costs but also long-term operational expenses and guest satisfaction. A thorough manufacturer comparison should extend beyond mere price points to encompass product quality consistency, production capacity, adherence to international standards, customization capabilities, and after-sales support. Reputable manufacturers like Longshow Textile, with extensive experience in the hotel bedding sector, distinguish themselves through their rigorous quality control protocols and ability to meet bulk demands without compromising on the luxurious feel and durability required for premium hospitality environments. They often possess certifications such as ISO 9001 for quality management and OEKO-TEX Standard 100, guaranteeing that their products are free from harmful substances, which is increasingly important for guest health and safety. Furthermore, their expertise in sourcing specific cotton varieties, such as long-staple cotton for enhanced softness and resilience, ensures a superior end product. When considering options like a white quilt or full king size sheet sets, verifying the manufacturer's consistency in material sourcing and weaving techniques is essential to guarantee uniform quality across large orders.

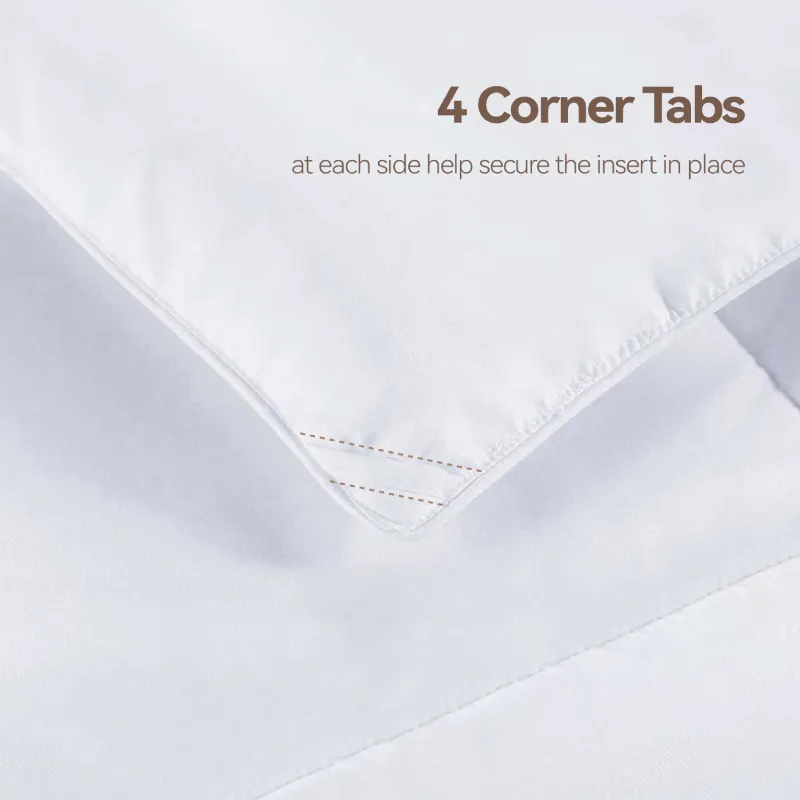

Customization is a significant advantage offered by leading bedding manufacturers, allowing hotels to differentiate their brand and meet unique aesthetic or functional requirements. This can range from bespoke sizes for specialized king bedding configurations to specific weave patterns that align with a hotel's interior design theme. Color matching is another crucial aspect of customization; for instance, a hotel seeking a specific calming ambiance might request exact Pantone matches for their sage green bedding, ensuring consistency across all textile elements. Custom branding, such as embroidered logos or woven labels on the sheets or duvet inserts, provides a subtle yet effective way to reinforce brand identity. For the product "Wholesale Hotel Bedding Comforter Duvet Insert" (URL: https://www.longshowtextile.com/wholesale-hotel-bedding-comforter-duvet-insert.html), customization might involve specific fill materials (e.g., down alternative, microfiber), varying fill weights for different climates (ideal for a lightweight summer quilt or a heavier winter option), or unique quilting patterns to complement the overall room aesthetic. These tailored solutions not only cater to specific design visions but also address practical considerations like desired thermal properties and maintenance protocols. Partnering with a manufacturer capable of delivering such comprehensive customization while maintaining strict quality controls provides a competitive edge in the luxury hospitality market, ensuring that every detail contributes to an unparalleled guest experience.

Real-World Applications and Case Studies in Premium Bedding

The application of high-quality cotton bed sheets extends across various segments within the hospitality and healthcare industries, each with unique demands. In luxury hotels and resorts, premium king bedding and king size sheet sets are foundational elements that define the guest experience. For example, a five-star resort in a tropical climate would prioritize breathable, moisture-wicking percale cotton bed sheets combined with a light summer quilt to ensure optimal guest comfort, even on warm nights. A boutique hotel focused on serene aesthetics might opt for custom-dyed sage green bedding to complement its natural design theme, requiring a manufacturer with precise color matching capabilities and a commitment to maintaining colorfastness through commercial laundering. A significant case study involves a major international hotel chain that transitioned their entire linen inventory to Longshow Textile's OEKO-TEX certified, 300-thread count sateen cotton bed sheets. Over two years, this chain reported a 15% reduction in linen replacement costs due to the enhanced durability and tear resistance of the new sheets, alongside a measurable increase in positive guest reviews specifically mentioning sleep quality and bedding comfort, directly impacting their repeat booking rates.

Beyond traditional hotels, healthcare facilities, including hospitals, clinics, and long-term care homes, also represent a significant application area for specialized cotton bed sheets. Here, the emphasis shifts slightly from luxury to hygiene, durability, and patient comfort. Sheets must withstand aggressive washing cycles at high temperatures to ensure sterilization, while remaining soft enough to prevent skin irritation, particularly for bedridden patients. Flame retardant treatments and antimicrobial finishes are often specified, adding another layer of technical requirement. An example application involves a large medical center that implemented Longshow Textile's specially treated white quilt sets and cotton bed sheets, which were engineered for superior resistance to bleach and repeated high-temperature laundering. This resulted in an extended service life for their linen inventory, reducing procurement frequency by 20% annually, while maintaining stringent hygiene standards. Furthermore, the inherent breathability of cotton assists in thermal regulation, which is crucial for patient comfort and preventing pressure sores. These real-world applications underscore that the choice of cotton bed sheets is not merely a matter of aesthetics or initial cost, but a strategic investment that profoundly impacts operational efficiency, cost management, guest/patient satisfaction, and overall brand reputation within diverse professional environments.

Frequently Asked Questions (FAQ) about Wholesale Hotel Bedding

Navigating the complexities of wholesale bedding procurement often raises several common questions from B2B clients. Below are answers to frequently asked questions concerning cotton bed sheets and related products, aiming to provide clarity and build trust.

-

Q: What is the ideal thread count for hotel cotton bed sheets?

A: While luxury properties may opt for 400-600 TC, a 250-300 TC percale or sateen weave is generally considered ideal for most hotels. This range balances durability for commercial laundering with a soft, comfortable feel. Higher thread counts don't always equate to higher quality, especially if achieved through multi-ply yarns or inferior cotton. -

Q: How do you ensure the color consistency of customized bedding, like sage green bedding?

A: We utilize advanced color matching technologies and adhere to strict dyeing protocols, including spectrophotometer analysis, to ensure precise Pantone matching and batch-to-batch consistency. Our fabrics also undergo rigorous colorfastness testing against washing and light exposure to guarantee long-term vibrancy. -

Q: What certifications do your king bedding products hold?

A: Our products, including king size sheet sets and our Wholesale Hotel Bedding Comforter Duvet Insert, are OEKO-TEX Standard 100 certified, ensuring they are free from harmful substances. Our manufacturing processes are also ISO 9001 certified for quality management systems, demonstrating our commitment to consistent product quality and customer satisfaction. -

Q: Can your summer quilt options be used year-round?

A: Our summer quilt selections are specifically designed to be lightweight and breathable for warmer climates or seasons. While they offer excellent comfort, for colder environments or winter seasons, we recommend our heavier fill duvet inserts to ensure optimal thermal regulation for guests.

-

Q: What is the estimated service life of your hotel-grade cotton bed sheets?

A: With proper commercial laundering and care, our hotel-grade cotton bed sheets are designed to last for 3 to 5 years, providing an excellent return on investment for hospitality businesses due to their superior durability and resistance to wear and tear. -

Q: Do you offer customizable options for the "Wholesale Hotel Bedding Comforter Duvet Insert"?

A: Yes, we offer extensive customization for our duvet inserts, including various fill materials (e.g., microfiber, down alternative), different fill weights for specific thermal needs, and custom sizing to perfectly fit your king bedding or other bed dimensions. We can also discuss custom quilting patterns or shell fabrics to meet your aesthetic preferences, such as for a specific white quilt look.

Commitment to Excellence: Delivery, Warranty, and Support

At Longshow Textile, our commitment to our B2B partners extends beyond providing superior cotton bed sheets and bedding products. We understand that reliable logistics, comprehensive warranties, and responsive customer support are as crucial as product quality for maintaining seamless operations in the hospitality sector. Our streamlined order processing and global distribution network are designed to ensure efficient delivery of bulk orders, whether it’s a standard shipment of king size sheet sets or a custom order of sage green bedding. Typical lead times for standard products range from 4-6 weeks for production and shipping, depending on order volume and destination. For bespoke solutions or very large quantities, a detailed timeline is provided at the quotation stage, ensuring transparency and enabling our clients to plan their inventory effectively. We pride ourselves on meeting agreed-upon deadlines, minimizing any potential disruption to our clients' operations. This logistical precision is critical for maintaining inventory levels and ensuring that guests consistently experience the comfort and luxury associated with high-quality linens, including our Wholesale Hotel Bedding Comforter Duvet Insert.

To underscore our confidence in the durability and craftsmanship of our products, Longshow Textile offers a robust warranty program covering manufacturing defects for a specified period, typically one year from the date of purchase. This warranty assures our clients of our dedication to product integrity and provides peace of mind for their investment in premium cotton bed sheets. Beyond the warranty, our dedicated customer support team is available to assist with any inquiries, from technical specifications of our king bedding to advice on optimal care for a white quilt or a summer quilt. We offer comprehensive after-sales support, including guidance on industrial laundering best practices to maximize the service life of our linens and maintain their aesthetic appeal. Our proactive communication ensures that clients are kept informed at every stage, from order confirmation to post-delivery feedback. This holistic approach to client relationships, combining superior product quality with reliable logistics, strong warranties, and expert support, solidifies Longshow Textile's position as a trusted partner for hospitality businesses seeking to elevate their guest experience through exceptional bedding solutions.

Authoritative References

- ASTM International Standards on Textiles and Materials.

- International Organization for Standardization (ISO) Quality Management Standards.

- OEKO-TEX Association: Standard 100 for textile product safety.

- Global Organic Textile Standard (GOTS) for organic fiber processing.

- American Association of Textile Chemists and Colorists (AATCC) Test Methods.

-

Garment Washed Sheets Color Retention Prevents Fading After WashesNewsNov.14, 2025

-

Charcoal Bamboo Sheets Moisture-Wicking Property Enhances Sleep ComfortNewsNov.12, 2025

-

High Quality Satin Sheets Soft Touch Improves Hotel Guest ExperienceNewsNov.12, 2025

-

Poly Cotton Sheets Breathable Weave Reduces Skin Irritation For PatientsNewsNov.12, 2025

-

Microfiber Sheet Stain Resistant Feature Eases Hotel HousekeepingNewsNov.12, 2025

-

Polyester Cotton Bedding Durable Fabric Withstands Frequent Hotel WashesNewsNov.12, 2025

-

Microfiber Pillow Filling Even Distribution Prevents LumpingNewsNov.03, 2025