Premium King Bed Sets: Luxury Cotton & Tencel for Ultimate Comfort

Understanding the Modern King Bed Set for B2B Applications

In the discerning B2B landscape, particularly within the hospitality, healthcare, and luxury accommodation sectors, the selection of a high-quality king bed set is paramount. It extends beyond mere aesthetics, encompassing critical factors such as material science, manufacturing precision, longevity, and overall guest comfort. A premium king bed set is an investment designed to enhance user experience, project an image of quality, and withstand the rigorous demands of commercial laundering and continuous use. This comprehensive overview delves into the technical specifications, industry trends, and strategic considerations for procuring superior bedding solutions.

Our focus includes not only the sheets and pillowcases but also the integration of specialized components like wholesale hotel Jacquard decorated bed skirts with elastic, which significantly contribute to the overall presentation and durability. The underlying objective for B2B buyers is to achieve an optimal balance between initial investment and long-term value, driven by performance, maintainability, and guest satisfaction.

Current Industry Trends and Market Dynamics

The commercial bedding industry is currently influenced by several significant trends. Sustainability is a primary driver, with an increasing demand for environmentally friendly materials and production processes. This has led to a surge in the popularity of organic sheets and tencel sheets, known for their reduced environmental footprint and luxurious feel. Furthermore, the focus on hygiene and ease of maintenance in high-traffic environments has led to innovations such as the coverless duvet, streamlining housekeeping operations while maintaining comfort.

Material science continues to evolve, offering advanced blends that provide enhanced durability, breathability, and wrinkle resistance. While traditional cotton sheets remain a staple, especially those with high thread counts and long-staple fibers, newer synthetic and semi-synthetic options are gaining traction for specific performance attributes. Customization also plays a pivotal role, with B2B clients seeking bespoke solutions that align with their brand identity, encompassing specific dimensions, patterns, and embedded logos. The market for larger bedding, including the queen bed set and king bed set, continues to see robust growth, driven by consumer preference for spacious sleep environments in both hospitality and residential sectors.

Technical Specifications and Parameters

A superior king bed set is defined by its meticulous technical specifications, which dictate its performance, comfort, and longevity. Key parameters include thread count (TC), material composition, weave type, dimensional accuracy, and colorfastness. For institutional use, a thread count between 300 and 800 TC is typically preferred, balancing luxurious feel with durable construction. Materials range from 100% long-staple Egyptian or Supima cotton, prized for its strength and softness, to blends incorporating Tencel Lyocell for enhanced breathability and moisture-wicking properties, or durable polyester blends for extreme resilience and quick-drying characteristics.

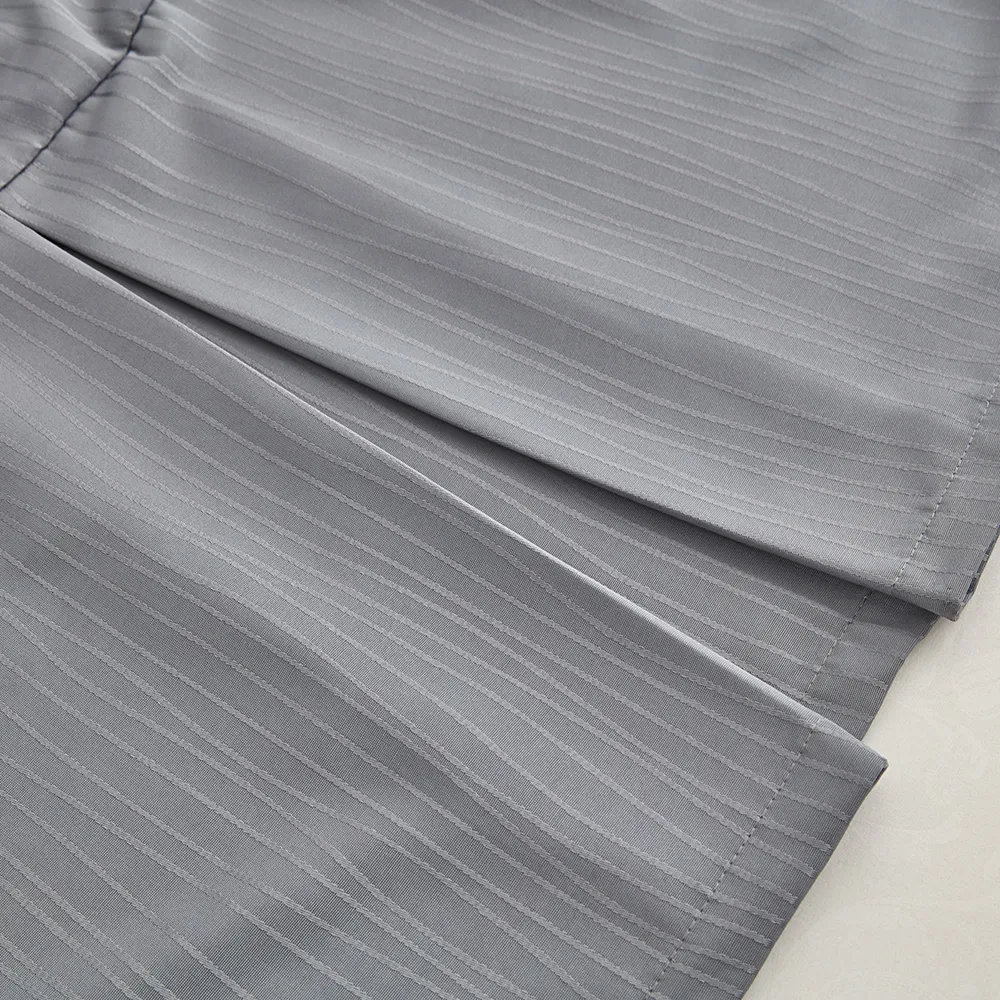

Weave types, such as sateen, percale, and twill, also contribute distinct characteristics. Sateen offers a silky-smooth finish and subtle sheen, while percale provides a crisp, cool feel. The dimensional stability, crucial for preventing shrinkage after repeated commercial laundering, is rigorously tested. Furthermore, a high-quality king bed set adheres to stringent standards for pilling resistance, tear strength, and abrasion resistance, ensuring it maintains its integrity and appearance over an extended service life. The elasticized Jacquard decorated bed skirt component often utilizes a durable polyester blend to withstand repeated stretching and maintain its decorative pattern.

Typical King Bed Set Specifications for B2B Applications

| Feature | Typical Specification (King Bed Set) | Key Performance Indicator |

|---|---|---|

| Material Composition | 100% Long-Staple Cotton, Tencel Lyocell, or Cotton/Polyester Blends | Comfort, Durability, Breathability |

| Thread Count (TC) | 300-800 TC | Softness, Density, Longevity |

| Weave Type | Sateen, Percale, Twill | Texture, Feel, Appearance |

| Duvet Cover Dimensions | 260 x 220 cm (approx. 102 x 87 in) | Fit for King Size Duvet Inserts |

| Flat Sheet Dimensions | 280 x 300 cm (approx. 110 x 118 in) | Generous Tuck-in Allowance |

| Fitted Sheet Dimensions | 198 x 203 x 35 cm (approx. 78 x 80 x 14 in) | Secure Fit for Deep Mattresses |

| Pillow Sham Dimensions | 50 x 90 cm (x2) (approx. 20 x 36 in) | Accommodates King Size Pillows |

| Colorfastness Rating | Grade 4+ (ISO 105-C06) | Resistance to Fading During Washing |

| Shrinkage Rate | Dimensional Stability | |

| Pilling Resistance | Grade 4+ (ISO 12945-2) | Resistance to Fabric Surface Deterioration |

Manufacturing Process Flow for a Premium King Bed Set

The production of a high-grade king bed set involves a sophisticated multi-stage process, meticulously controlled to ensure consistency and quality. Each step, from raw material selection to final packaging, adheres to stringent industrial standards.

-

Raw Material Sourcing & Selection:

This foundational step involves the procurement of premium fibers such as long-staple cotton (e.g., Supima, Egyptian), Tencel Lyocell, or high-grade polyester. Selection is based on fiber length, strength, uniformity, and adherence to environmental certifications like GOTS (Global Organic Textile Standard) for organic sheets or FSC for wood-derived fibers.

-

Yarn Spinning:

Selected fibers are cleaned, carded, and spun into fine, strong yarns. Advanced spinning techniques, such as ring spinning, are employed to produce smooth, even threads crucial for achieving high thread counts and preventing pilling in finished cotton sheets or tencel sheets.

-

Weaving/Knitting:

Yarns are then woven into fabric using industrial looms. This stage determines the weave type (sateen, percale, twill) and intricate patterns, such as the Jacquard design for bed skirts. Precision weaving ensures consistent fabric density and structural integrity, adhering to standards like ASTM D3775 for fabric width and ASTM D3776 for fabric weight.

-

Pre-treatment & Dyeing:

The grey fabric undergoes pre-treatment processes including scouring, mercerization (for cotton to enhance strength and dye uptake), and bleaching. This is followed by reactive dyeing, ensuring deep, vibrant, and highly colorfast results that meet ISO 105 standards for textile colorfastness, critical for commercial laundering cycles.

-

Finishing:

Various finishing treatments are applied to achieve desired hand-feel, wrinkle resistance, and dimensional stability. This can include sanforizing (for controlled shrinkage), calendering (for smoothness), and specialized anti-microbial or moisture-wicking finishes. This step is vital for the perceived quality and practicality of a king bed set in a hospitality setting.

-

Cutting & Sewing:

Automated CNC cutting machines precisely cut fabric into specific patterns for flat sheets, fitted sheets, duvet covers, pillow shams, and bed skirts. Industrial sewing machines with reinforced stitching (e.g., French seams, overlock stitches) assemble these components, ensuring robust seams capable of withstanding hundreds of wash cycles. Elastic components for bed skirts are meticulously integrated for a secure fit.

-

Quality Control & Inspection:

Throughout the entire process, multiple quality control checkpoints are established. Final inspection involves checking for fabric defects, stitching integrity, dimensional accuracy, color consistency, and overall compliance with product specifications and international standards like ISO 9001 and Oeko-Tex Standard 100. This rigorous testing ensures optimal service life.

-

Packaging & Distribution:

Each finished king bed set is individually inspected, folded, and packaged in protective, often vacuum-sealed, commercial-grade packaging, ready for bulk shipment to target industries such as hotels, resorts, and healthcare facilities.

Technical Advantages and Performance Metrics

The technical advantages of a well-engineered king bed set for B2B applications are manifold, translating directly into operational efficiencies and enhanced client satisfaction. Key advantages include:

- Superior Durability & Longevity: Engineered to withstand intensive commercial laundering cycles (typically 300+ washes at high temperatures) without significant degradation in fabric integrity, color vibrancy, or dimensional stability. This reduces the frequency of replacement, yielding substantial cost savings over the product's service life.

- Enhanced Comfort & Guest Experience: High thread count cotton sheets or soft tencel sheets offer exceptional breathability, moisture-wicking, and a luxurious hand-feel, directly contributing to elevated guest comfort and positive reviews for hospitality businesses.

- Low Maintenance & Operational Efficiency: Features like wrinkle-resistant finishes, quick-drying fabrics, and robust construction streamline laundry processes and reduce labor costs for housekeeping staff. The ease of applying and securing a wholesale hotel Jacquard decorated bed skirt with elastic is a practical advantage.

- Hypoallergenic & Hygienic Properties: Many premium sets utilize materials and finishes that are naturally hypoallergenic or incorporate antimicrobial treatments, crucial for healthcare and hospitality environments to ensure a sanitary sleeping surface. Compliance with Oeko-Tex Standard 100 ensures absence of harmful substances.

- Aesthetic Appeal & Brand Consistency: Precision weaving, high-quality dyeing, and design details like Jacquard patterns or embroidery ensure a consistently elegant appearance, reinforcing brand image and contributing to the overall ambiance of the room.

- Energy Saving: Modern fabric technologies and weave structures can sometimes contribute to better thermal regulation, potentially leading to marginal energy savings in climate control for large-scale operations. For example, breathable fabrics reduce the need for excessive air conditioning.

- Corrosion Resistance: While not typically applicable to textiles, the manufacturing environment for these textiles often involves machinery requiring corrosion-resistant components, ensuring reliable production and consistent quality of the final textile product.

Application Scenarios and Target Industries

The demand for high-quality king bed set solutions extends across a variety of B2B sectors, each with unique requirements:

- Luxury Hospitality (Hotels, Resorts, Boutiques): These establishments prioritize premium feel, exceptional durability, and aesthetic consistency. They often demand specific thread counts (e.g., 600-800 TC for cotton sheets), custom sizes, and specialized designs, including the Jacquard decorated bed skirt for a refined room appearance.

- Healthcare Facilities (Hospitals, Clinics, Long-Term Care): Emphasis here is on hygiene, antimicrobial properties, ease of cleaning, and robust construction to withstand medical-grade laundering. Materials like polyester blends or specially treated tencel sheets are often preferred for their resilience and quick-drying nature.

- Cruise Lines & Marine Hospitality: Products must be resistant to environmental factors (e.g., humidity), highly durable, and compliant with marine safety standards. Space optimization might also lead to demand for solutions like a coverless duvet.

- Serviced Apartments & Extended Stay Accommodations: Durability, comfort comparable to residential use, and ease of replacement are key. A complete king bed set, including all necessary components, provides a seamless solution.

- High-End Residential Developments: Bulk orders for developers to furnish luxury apartments or homes, requiring commercial-grade quality with a residential aesthetic. This often includes full packages from a queen bed set to king sizes.

- Educational Institutions (Dorms, Faculty Housing): Focus on extreme durability, washability, and cost-effectiveness for long-term use.

Vendor Comparison and Selection Criteria

Choosing the right vendor for a king bed set is a strategic decision for B2B buyers. It requires evaluating not only the product itself but also the manufacturer's capabilities, reliability, and support infrastructure. Key criteria for vendor comparison include product quality, customization capabilities, adherence to certifications, lead times, pricing models, and after-sales service. A detailed comparison ensures alignment with specific operational and budgetary requirements.

Comparative Analysis of B2B Bedding Vendors

| Feature/Criterion | Premium Vendor (e.g., Longshow Textile) | Mid-Range Vendor | Value-Focused Vendor |

|---|---|---|---|

| Product Quality & Materials | Exceptional (800TC Long-Staple Cotton, Organic Tencel sheets, Advanced Blends, Jacquard Weaves) | Good (400-600TC Cotton sheets, Standard Polyester Blends) | Standard (200-300TC Cotton/Polyester Blends) |

| Customization Capabilities | Extensive (Custom sizes, thread counts, materials, patterns, branding, Jacquard designs) | Moderate (Limited sizes, color options, basic branding) | Minimal (Standard sizes only, no custom patterns) |

| Certifications & Standards | ISO 9001, Oeko-Tex Standard 100, GOTS (for organic sheets) | Oeko-Tex Standard 100 | Basic internal quality checks |

| Lead Time (Bulk Orders) | 4-6 Weeks (optimized for efficiency) | 6-8 Weeks | 8-12 Weeks |

| Warranty & Support | Comprehensive 2-year warranty, dedicated account management, full after-sales support | 1-year limited warranty, standard customer service | 6-month warranty, basic support |

| Price Point (King Bed Set) | Premium (Higher initial investment, lower total cost of ownership) | Mid-Range | Economical (Lower initial cost, potentially higher long-term replacement) |

Customized Solutions for Specialized Needs

Recognizing the diverse requirements of the B2B market, leading manufacturers offer extensive customization options for their king bed set products. These tailor-made solutions ensure perfect integration with a client's specific operational needs and brand identity.

- Material and Blend Customization: From proprietary blends of cotton sheets and Tencel to specialized polyester fabrics with specific performance attributes (e.g., flame retardancy, extreme stain resistance), clients can specify the exact material composition.

- Dimensional Modifications: Accommodation of non-standard mattress sizes or unique bed frames, ensuring a precise fit for every component of the king bed set, including bespoke fitted sheets and duvet covers.

- Design and Pattern Development: Creation of exclusive Jacquard patterns for bed skirts or duvet covers, custom embroidery of logos on pillow shams, or unique color matching to a specific brand palette. This includes the intricate designs seen on the wholesale hotel Jacquard decorated bed skirt with elastic.

- Functional Enhancements: Integration of specialized finishes such as permanent antimicrobial treatments, advanced wrinkle resistance for reduced ironing, or quick-dry properties for faster laundry cycles.

- Packaging Solutions: Custom bulk packaging for efficient storage and distribution, or individual packaging tailored for retail distribution in a hotel gift shop.

Application Case Studies: Real-World Impact

Illustrating the tangible benefits of high-performance king bed set solutions, these case studies demonstrate their impact across various B2B environments.

Case Study 1: Luxury Boutique Hotel Chain

A high-end boutique hotel chain, seeking to elevate its guest experience and reduce linen replacement costs, partnered with a premium textile manufacturer. They implemented a custom king bed set featuring 800 TC long-staple cotton sheets with a sateen weave, complemented by a bespoke Jacquard decorated bed skirt with elastic for every king-sized bed. Post-implementation data showed a 15% increase in guest satisfaction scores related to bedding comfort and quality within the first year. Furthermore, the exceptional durability of the linens led to a 20% reduction in annual replacement costs compared to their previous supplier, demonstrating significant ROI and an enhanced brand image.

Case Study 2: Major Cruise Line

A leading international cruise line faced challenges with frequent linen replacement due to the harsh marine environment and intensive laundering. They opted for a specialized king bed set and queen bed set fabricated from an advanced polyester-Tencel blend. This blend offered superior resistance to mildew, exceptional quick-drying properties, and remarkable tear strength, extending the service life of each set by 40%. The incorporation of easy-to-manage coverless duvet options further streamlined cabin turnover times, contributing to improved operational efficiency across their fleet. The initial investment was offset by substantial long-term savings in procurement and labor.

Ensuring Quality: Certifications and Standards

Authoritativeness in the B2B textile sector is built upon adherence to recognized international standards and certifications. For a king bed set, these benchmarks guarantee not only product quality but also ethical and environmental responsibility.

- ISO 9001 (Quality Management Systems): Certification demonstrates a commitment to consistent quality production, continuous improvement, and customer satisfaction throughout the manufacturing process of every king bed set.

- Oeko-Tex Standard 100: This globally recognized certification ensures that every component of the textile product, including all threads, buttons, and other accessories, has been tested for harmful substances and is therefore harmless for human health. This is particularly vital for bedding used in sensitive environments like healthcare or children's accommodations.

- GOTS (Global Organic Textile Standard): For organic sheets and other organic textile products, GOTS certification verifies the organic status of textiles from harvesting of the raw materials, through environmentally and socially responsible manufacturing, up to labeling.

- ASTM International Standards: Various ASTM standards apply to textile testing, including those for tear strength (e.g., ASTM D1424), abrasion resistance (e.g., ASTM D3884), and pilling resistance (e.g., ASTM D3512), ensuring the physical performance of the king bed set.

Customer Experience and Feedback

Client testimonials and continuous feedback loops are integral to refining products and services. Our long-standing partners consistently highlight the exceptional durability and aesthetic retention of our king bed set offerings, even after years of rigorous commercial use. For instance, a major hotel group reported: "The transition to Longshow Textile's king bed set, including their high-quality Jacquard bed skirts, resulted in noticeable improvements in both guest comfort scores and linen lifecycle. Our housekeeping staff appreciates the ease of care and the consistent, pristine appearance, which significantly contributes to our brand's luxury perception." This feedback underscores the tangible benefits of investing in high-quality, B2B-specific bedding solutions.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Building trust with B2B clients requires transparency and robust support infrastructure. We provide clear commitments on product quality, fulfillment, and after-sales service.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for a bulk order of king bed set components?

A: Standard lead times for bulk orders (e.g., 500+ sets) range from 4 to 6 weeks, depending on customization requirements and current production schedules. Express options may be available upon request. - Q: What is the recommended care for these commercial cotton sheets and sets?

A: Our products are designed for commercial laundering. We recommend washing at temperatures up to 60°C (140°F) with a neutral detergent, followed by tumble drying on medium heat. Avoid harsh bleaches unless specified for white goods. Detailed care instructions are provided with each order. - Q: Do you offer samples for evaluation prior to bulk purchase?

A: Yes, we provide sample sets for B2B clients to evaluate material quality, finish, and fit. Please contact our sales team to arrange sample delivery. - Q: Can the Jacquard decorated bed skirt be customized with our hotel logo?

A: Absolutely. We offer comprehensive customization, including embroidered logos on pillow shams, custom Jacquard patterns for bed skirts, and specific color matching to align with your brand guidelines.

Lead Time and Fulfillment

Our integrated supply chain management and efficient manufacturing processes allow for optimized lead times for wholesale king bed set orders. We provide transparent communication throughout the order fulfillment process, from initial inquiry to final delivery. Logistics solutions are tailored to client needs, including international shipping and customs support.

Warranty Commitments

We stand behind the quality of our products. All commercial king bed set components, including the wholesale hotel Jacquard decorated bed skirt with elastic, come with a comprehensive 2-year manufacturer's warranty against defects in materials and workmanship under normal commercial use and care. This warranty covers issues such as excessive shrinkage, premature pilling, or seam failures not attributed to improper use or laundering.

Customer Support and After-Sales Service

Our dedicated B2B customer support team is available to assist with any inquiries, order tracking, technical support, or post-purchase concerns. We provide direct contact with account managers who understand your specific industry needs, ensuring prompt and effective resolution. Our commitment extends beyond delivery, fostering long-term partnerships built on trust and mutual success.

Conclusion

The strategic procurement of a premium king bed set is a critical decision for B2B enterprises aiming for operational excellence and superior client satisfaction. By focusing on advanced materials, precise manufacturing, adherence to international quality standards, and robust after-sales support, businesses can invest in bedding solutions that offer unparalleled durability, comfort, and aesthetic appeal. Partnering with a specialized manufacturer that understands the nuanced demands of the B2B market ensures not only high-quality products but also a long-term, value-driven relationship. This holistic approach to bedding procurement ultimately enhances brand reputation and contributes significantly to bottom-line success.

Citations

- International Organization for Standardization (ISO). ISO 9001:2015 - Quality management systems — Requirements.

- Oeko-Tex Association. Oeko-Tex Standard 100. Retrieved from oeko-tex.com.

- Global Organic Textile Standard (GOTS). GOTS Standard Version 6.0. Retrieved from global-standard.org.

- American Society for Testing and Materials (ASTM) International. Various standards for textile testing, including D1424, D3884, D3512. Retrieved from astm.org.

- Textile Exchange. "Material Change Index." (Annual industry report on sustainable materials). Retrieved from textileexchange.org.

-

Garment Washed Sheets Color Retention Prevents Fading After WashesNewsNov.14, 2025

-

Charcoal Bamboo Sheets Moisture-Wicking Property Enhances Sleep ComfortNewsNov.12, 2025

-

High Quality Satin Sheets Soft Touch Improves Hotel Guest ExperienceNewsNov.12, 2025

-

Poly Cotton Sheets Breathable Weave Reduces Skin Irritation For PatientsNewsNov.12, 2025

-

Microfiber Sheet Stain Resistant Feature Eases Hotel HousekeepingNewsNov.12, 2025

-

Polyester Cotton Bedding Durable Fabric Withstands Frequent Hotel WashesNewsNov.12, 2025

-

Microfiber Pillow Filling Even Distribution Prevents LumpingNewsNov.03, 2025