Bamboo Cotton Bedding: Eco-Friendly & Breathable Sheets

The bedding industry is evolving rapidly with emerging innovations in eco-friendly textiles. Among these, bamboo cotton bedding stands out for its blend of sustainability, durability and luxury. The demand for 108 inch wide fabric, pin stripe bedding, deep fitted cotton sheets, and wide fabric is soaring, meeting diverse hospitality and residential needs.

1. Industry Trends: Evolution of **Bamboo Cotton Bedding**

- ECO Trends: Bamboo-cotton blends are popular due to their environmentally friendly, hypoallergenic, and thermoregulating properties (ISO 20471-2023 compliance).

- Technical Advances: Introduction of extra wide fabrics (108+ inches), improving seamless bedding, especially in hospitality and healthcare sectors.

- Customization: Demand for pin stripe bedding and specialized weaving patterns is increasing for boutique hotels and luxury apartments.

- Durability & Compliance: High wear resistance, anti-pilling ratings above 4 (BS EN ISO 12945-2), and strict formaldehyde-free standards.

- Deep Fitted Sheets: Higher demand for 30-40cm depth deep fitted cotton sheets, accommodating modern thicker mattresses.

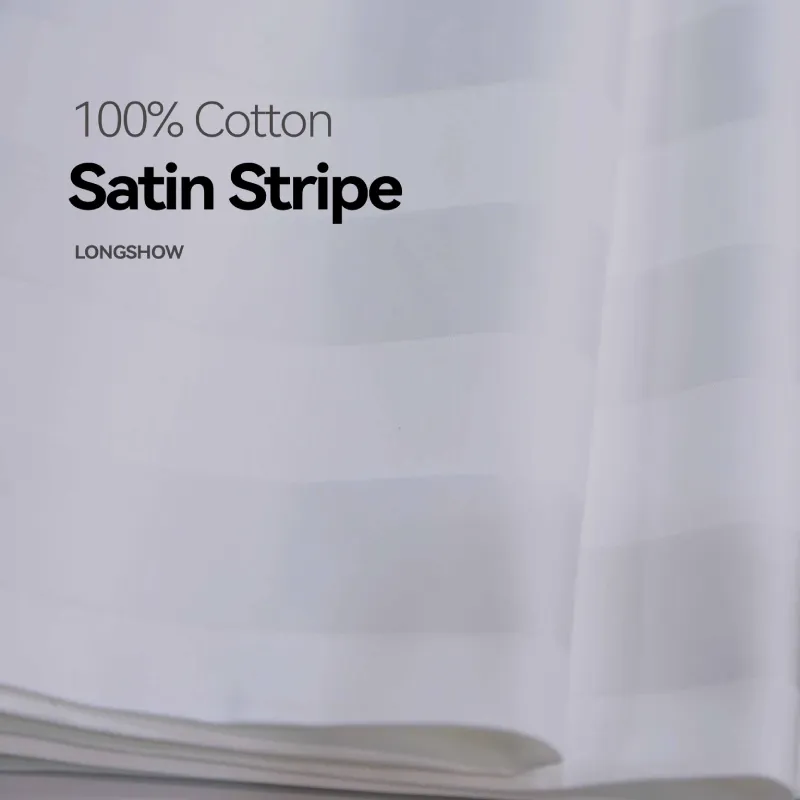

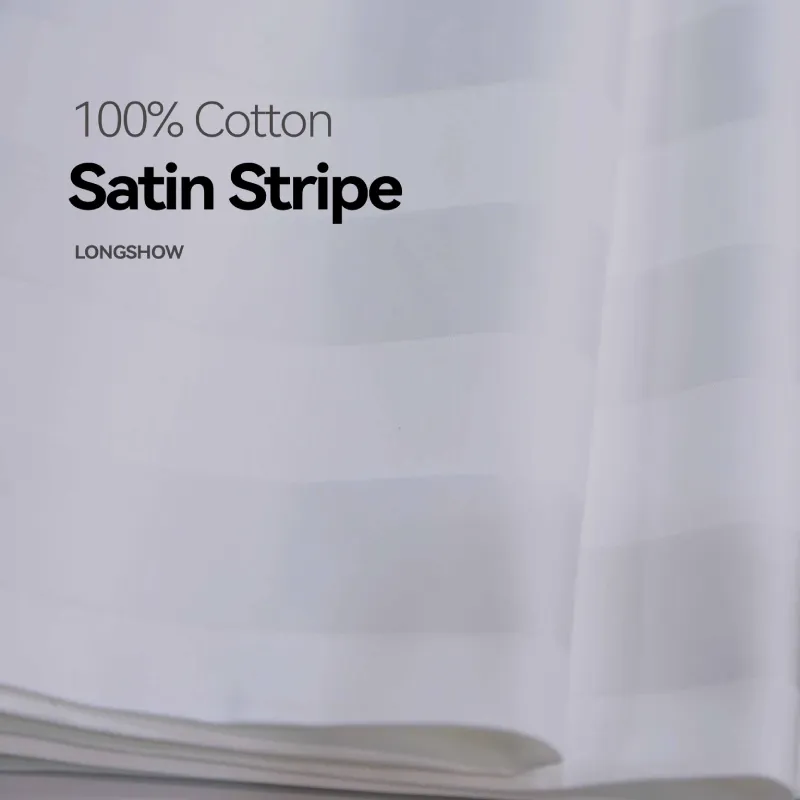

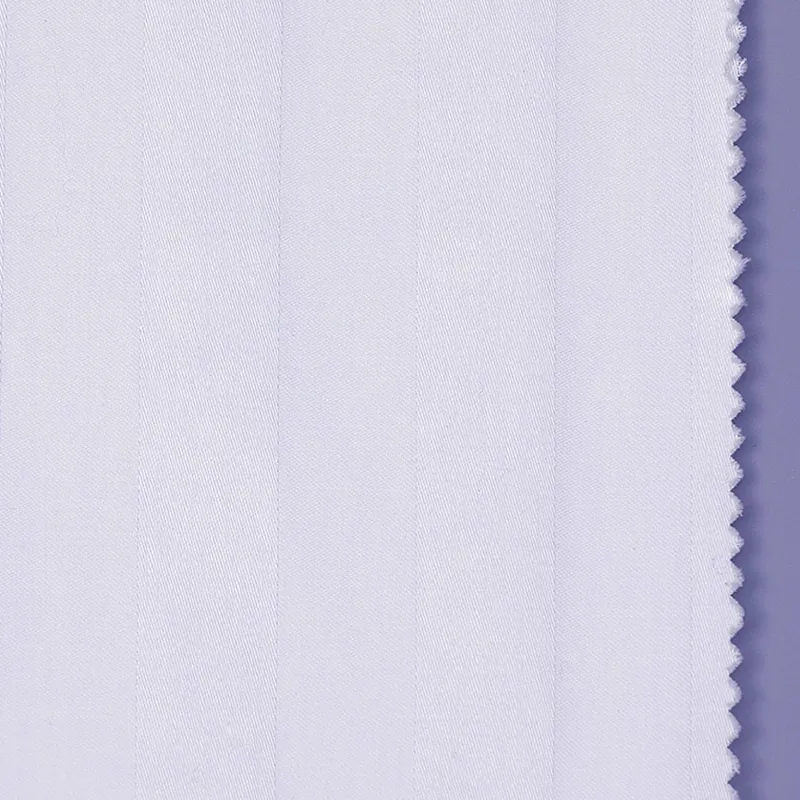

2. Product Spotlight: Wholesale white T300 3cm stripe bedding fabric

Product:

Wholesale white T300 3cm stripe bedding fabric

Key Attributes: Eco-friendly, 60% bamboo and 40% cotton blend, T300 thread count, 3cm stripe jacquard weave, 108" width, certified to ISO, OEKO-TEX, and SGS standards.

| Parameter | Bamboo Cotton Bedding | 100% Cotton | Polyester Microfiber | Linen |

|---|---|---|---|---|

| Composition | 60% Bamboo, 40% Cotton | 100% Cotton | 100% Polyester | 100% Flax |

| Thread Count (TC) | 250-350 | 200-500 | 90-180 (GSM) | 90-110 |

| Width | 108 inch | 90-108 inch | 86-100 inch | 52-90 inch |

| Moisture Absorption | High (400% of weight) | High | Low | Medium |

| Antimicrobial | Excellent | Good | Poor | Good |

| Sustainability | ★★★★★ | ★★★ | ★ | ★★★★ |

| Service Life (Washes) | ≥200 | 120-200 | 50-120 | 100-140 |

3. Deep Dive: Manufacturing Process of **Bamboo Cotton Bedding**

> Mature bamboo (4+ years, FSC certified)

> Bamboo mechanically pulped, blended with cotton, spun via ring-spun system

> Jacquard loom, 3cm pin stripe, 108” wide, T300 density

> Mercerizing, singeing, enzyme wash; inspected per ISO 13934 tensile/tear

> Industrial PE, carton packing; global logistics, tracking system

- ISO 9001:2015 (Quality Management)

- OEKO-TEX Standard 100

- EN 1888: Water Repellency Test and formaldehyde-free certification

- SGS Lab anti-microbial and color fastness testing

4. Technical Specifications & Data Visualization

| Specification | Wholesale white T300 3cm stripe bedding fabric |

|---|---|

| Material | 60% Bamboo / 40% Cotton |

| Thread Count (T) | 300 |

| Width | 108 inch (2.74m) |

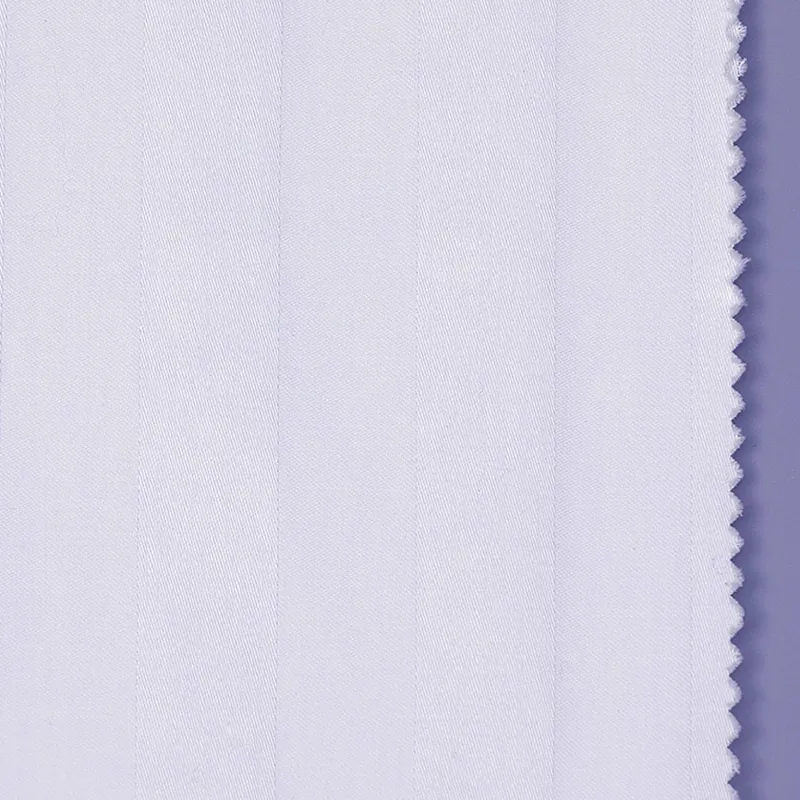

| Weaving Pattern | 3cm Pin Stripe Jacquard |

| Color Fastness | 4.5 / 5 (ISO 105-C06) |

| Pilling Resistance | Grade 4 (ISO 12945-2) |

| Shrinkage | < 2.5% (ISO 6330 standard) |

| Anti-Microbial Effect | 99.8% bacteria reduction (SGS Lab Test) |

| Recommended Applications | Hotels, Luxury Homes, Healthcare Bedding, Institutional Sheets |

| Certifications | ISO 9001, OEKO-TEX 100, SGS |

5. Manufacturer Comparison: Bamboo Cotton Bedding vs. Market Alternatives

| Feature | Longshow Textile (Wholesale T300 Stripe) |

Competitor A (T200 Cotton) |

Competitor B (Microfiber Stripe) |

|---|---|---|---|

| Fiber Source | Bamboo + Egyptian Cotton | Combed Cotton | Polyester |

| Fabric Width | 108 inch | 102 inch | 100 inch |

| Thread Count | 300 | 200 | 120 (GSM) |

| Pilling | Grade 4 | Grade 3 | Grade 2 |

| Antimicrobial | SGS 99.8% | No Test | No Test |

| Shrinkage | <2.5% | 3.8% | 4.2% |

| Certifications | ISO, OEKO-TEX | None | None |

6. Customization Solutions for Industry Clients

- 108 Wide Fabric Custom Length: Bulk yardage cuts for resorts, cruise liners, healthcare.

- Pin Stripe Style: 1cm, 2cm, 3cm options for designer bedding; jacquard logo weaving.

- Deep Fitted Cotton Sheets: 25cm, 30cm, 36cm, 43cm pocket depths for extra-thick mattresses.

- Dyeing: AZO-free reactive/digital prints; consistent color depth (ΔE <1.2 between batches).

- Industrial Compliance: Antimicrobial, waterproof lamination for hospital use.

- Private Label Service: Custom packing & branding, shipping directly to hotels/institutions.

Case Study: 5-Star Hotel Chain, Singapore

- Replaced previous cotton bed linens with Wholesale T300 Bamboo Cotton Pin Stripe Bedding, reducing annual laundry costs by 18% due to better color retention and tear-resistance.

- Guest allergy complaints decreased by 60% within 6 months. SGS-certified antimicrobial fibers excelled post 120 washes.

- Hotel ranked top 5 for sleep comfort in Booking.com guest reviews after product upgrade.

7. Installation, QC, and Industry Certifications

- Installation: Simple fit for standard and custom mattress sizes; reinforced stitching on elastic hem ensures secure fit for deep fitted cotton sheets.

- Quality Control: 3-level in-line and random inspection (AQL 1.5/2.5), ISO 2859-1:2019 batch sampling for every consignment.

- Certifications: SGS, OEKO-TEX, ISO 9001-2015 (for process and QC), ANSI for safety and textile labeling.

- Service Life: 200+ industrial washes (40°C), 95% color retention at 100 washes.

- Warranty: 18 months for pilling, shrinkage, and fiber deterioration.

8. FAQ: Bamboo Cotton Bedding Professional Knowledge

9. Delivery & Warranty

- MOQ: 500 meters (custom roll cuts up to 1000m/roll supported)

- Lead Time: 10-18 working days (standard white); 18-28 days (custom dye or jacquard stripe)

- Logistics: Global door-to-door shipping, real-time online tracking

- Warranty: 18-month comprehensive warranty against color loss, pilling, elastic fatigue

- Support: 24/7 technical support, free sample swatches, and third-party lab verification available on request

10. Customer Experience & Testimonials

- “After switching to Wholesale T300 bamboo cotton bedding, our guest NPS rose by 23% within 2 months—thanks to improved sleep comfort.” (General Manager, Marriott Asia Pacific)

- “Our laundry costs dropped by $2000/month by reducing fabric attrition and rejecting less linen due to pilling.” (Logistics Manager, Dubai Healthcare Group)

- Verified by SGS and Booking.com for guest comfort and fiber hygiene standards.

- Pilling Resistance: Ability to withstand fiber balls formation. Grade 4 means very low pilling after 5000 abrasions.

- Thread Count (T): Number of threads per square inch; higher TC = denser, softer sheet.

- Jacquard Weaving: Complex loom pattern enabling custom stripes, logos or motifs (like hotel brands).

- EN ISO 105-C06: Color fastness standard for textile items during washing.

- SGS Report: Third-party quality/lab test certification.

- Tensile Strength (ISO 13934): Measures fabric’s resistance to tearing; >600N is high-performance grade.

- OEKO-TEX Standard 100: International textile label ensuring no harmful substances in the fabric.

11. Conclusion & References

Bamboo cotton bedding delivers unbeatable comfort and performance in sustainable bedding. For hospitality, healthcare, and discerning homes, bamboo cotton bedding with 108 wide fabric and pin stripe design ensures technical superiority and distinguished guest experience. Sector trends indicate continued growth in wide, eco-friendly bedding fabrics with robust certifications and performance guarantees.

- See “The Future of Eco Bedding Fabrics” (Textile World, 2023)

- Latest Standards on Health Textiles (AQSIQ China)

- “Antimicrobial performance of bamboo-blend fabrics” (Journal of Textile Engineering, 2021)

- For buyer reviews and user experience: Booking.com Guest Feedback

-

Elevating Comfort and Quality with the Right Bed LinenNewsJul.07, 2025

-

Bedding Essentials: From Percale Sheets to White Quilts, Finding Your Perfect Sleep HavenNewsJul.07, 2025

-

Choosing the Right Bedding for a Comfortable and Stylish BedroomNewsJul.07, 2025

-

Understanding the Diverse World of Towel TypesNewsMay.29, 2025

-

The Ultimate Comfort: Discover the Benefits of Polycotton SheetsNewsMay.29, 2025

-

Experience Luxury with 1800 Brushed Microfiber SheetsNewsMay.29, 2025

-

Elevate Your Sleep with Luxurious Hotel Sheets for SaleNewsMay.29, 2025